Connecting structure of rotary connector and steering angle sensor

A rudder angle sensor, rotary connector technology, applied in flexible/rotatable wire connectors, connections, steering mechanisms, etc., can solve problems such as increased cost, spring ringing, poor assembly workability, etc., to eliminate vibration sound, reduce effect of noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

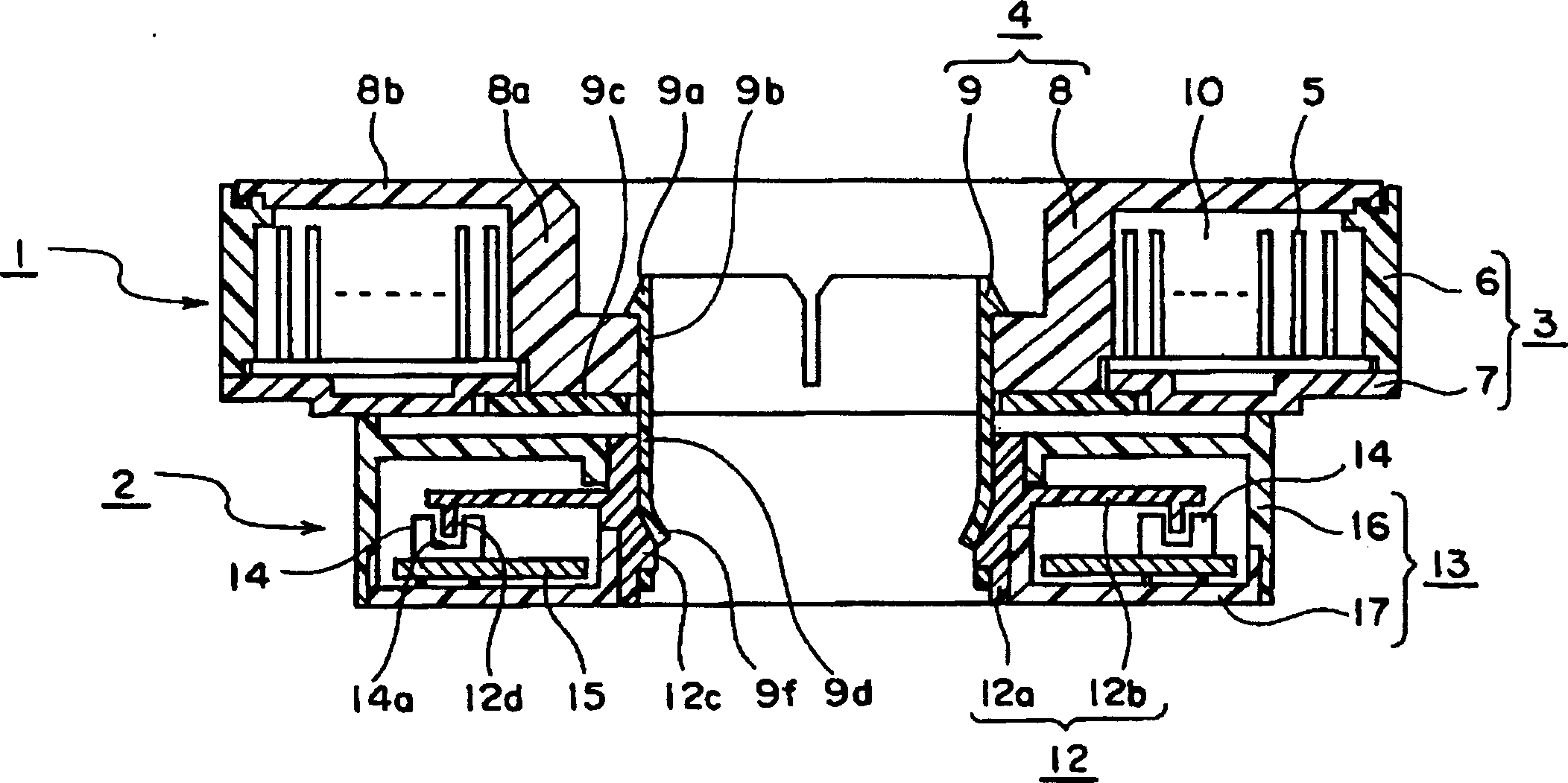

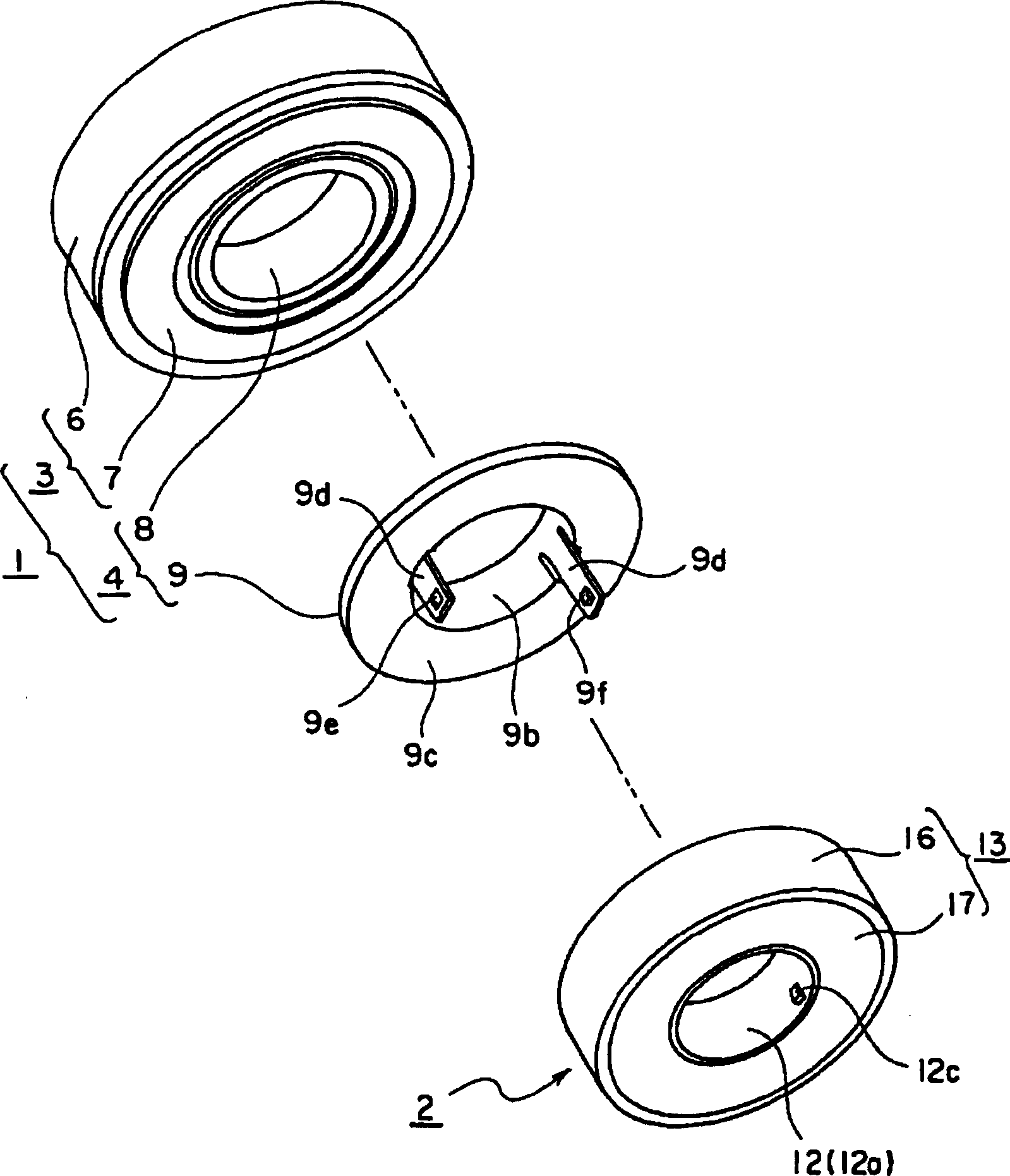

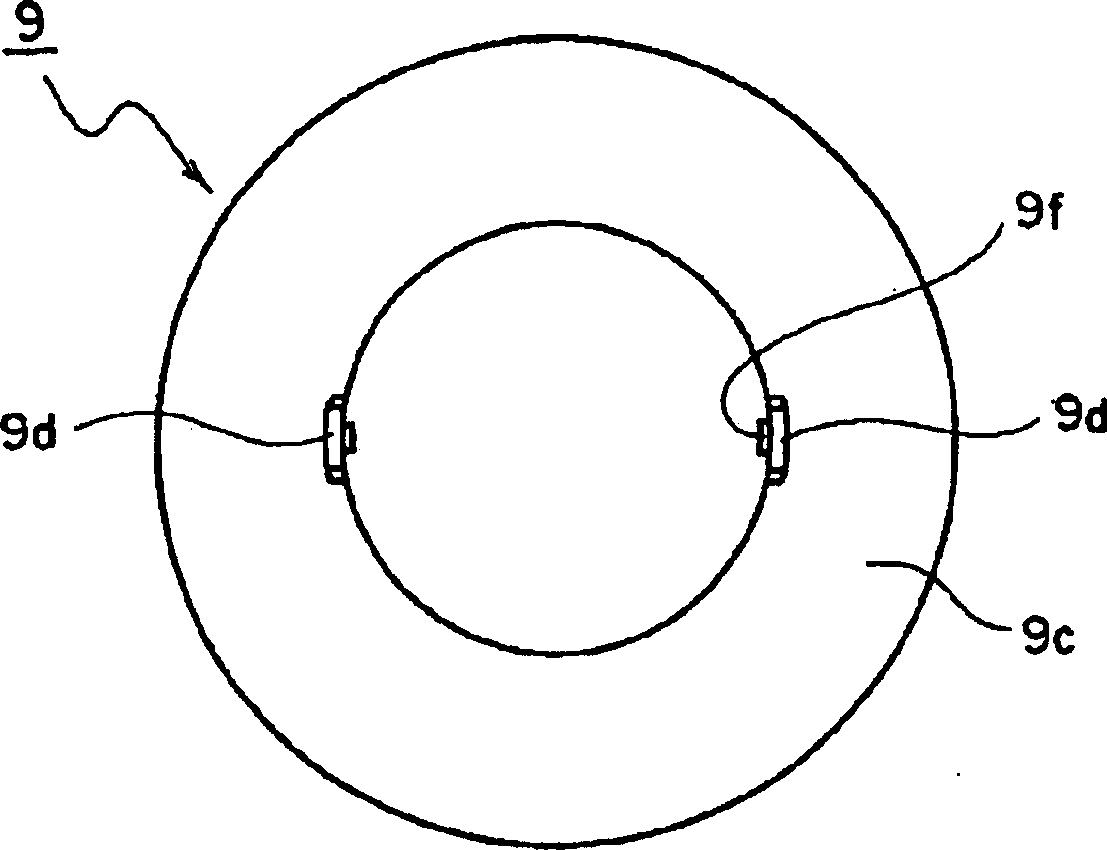

[0022] Embodiments of the invention will be described below with reference to the drawings. figure 1 It is a cross-sectional view showing a connection assembly of a rotary connector and a rudder angle sensor according to an embodiment of the present invention, figure 2 is an exploded perspective view of the connection assembly, image 3 In order to show the bottom view of the lower rotor of the swivel connector included in this connection assembly, Figure 4 is a sectional view of the lower rotor, Figure 5 It is an explanatory diagram showing the main part of the connecting portion of the lower rotor and the rotating member of the steering angle sensor.

[0023] The connecting assembly of the present embodiment is composed of a rotary connector 1 and a rudder angle sensor 2. As will be described later, these rotary connectors 1 and the rudder angle sensor 2 are assembled in a state in which they are stacked up and down in two stages. into the steering gear of the vehicle....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com