Pressure compensating flow control hydraulic circuit having holding valve

A technology of flow control and pressure compensation, applied in fluid pressure actuators, servo meter circuits, gas/liquid distribution and storage, etc., can solve problems such as difficulty in coordinating the driving speed of the arm, reducing usability and maneuverability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Hereinafter, preferred embodiments of the present invention will be described with reference to the accompanying drawings. Matters defined in the description, such as specific configurations and elements, are merely specific details provided to help those of ordinary skill in the art fully understand the present invention, and thus the present invention is not limited thereto.

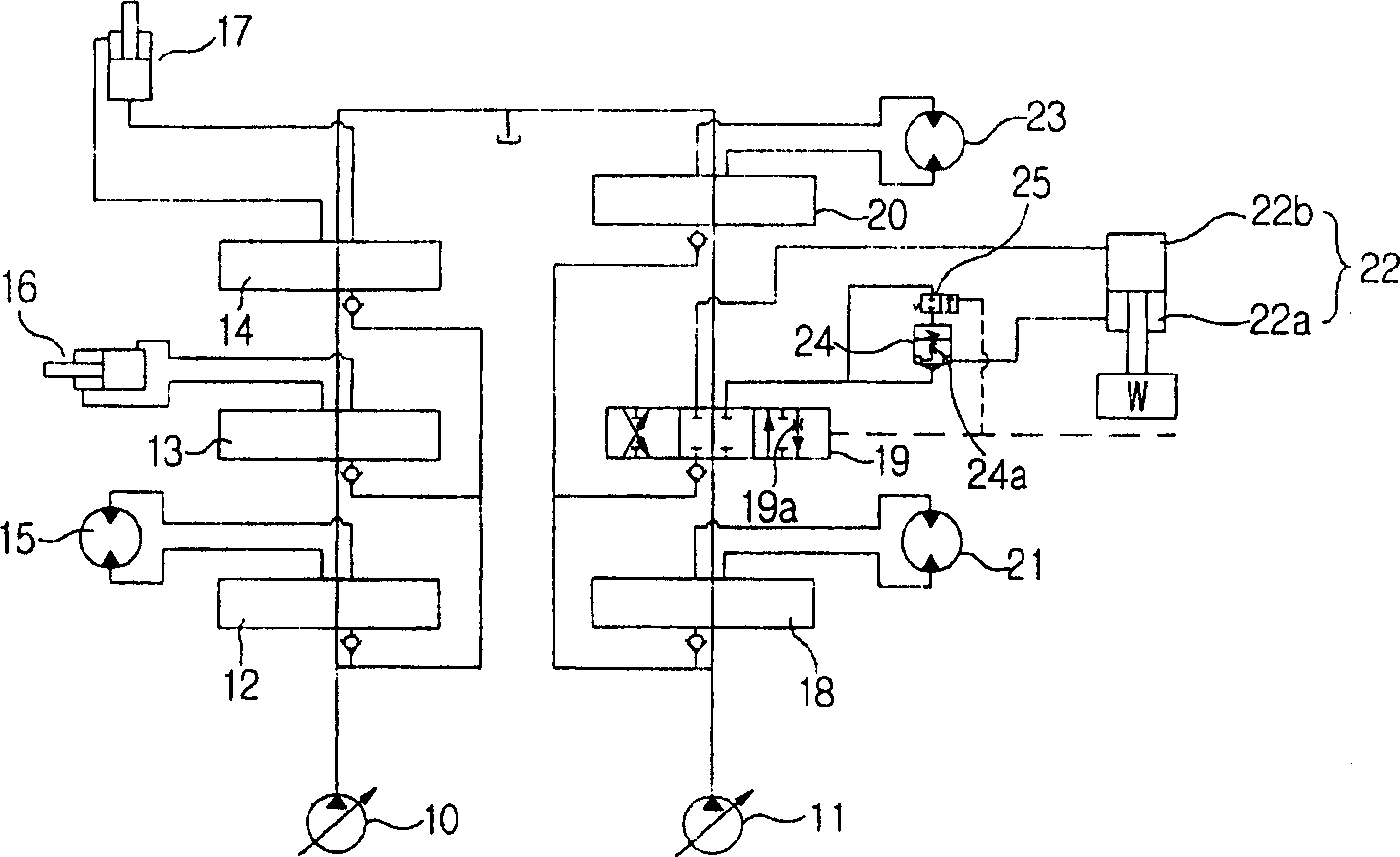

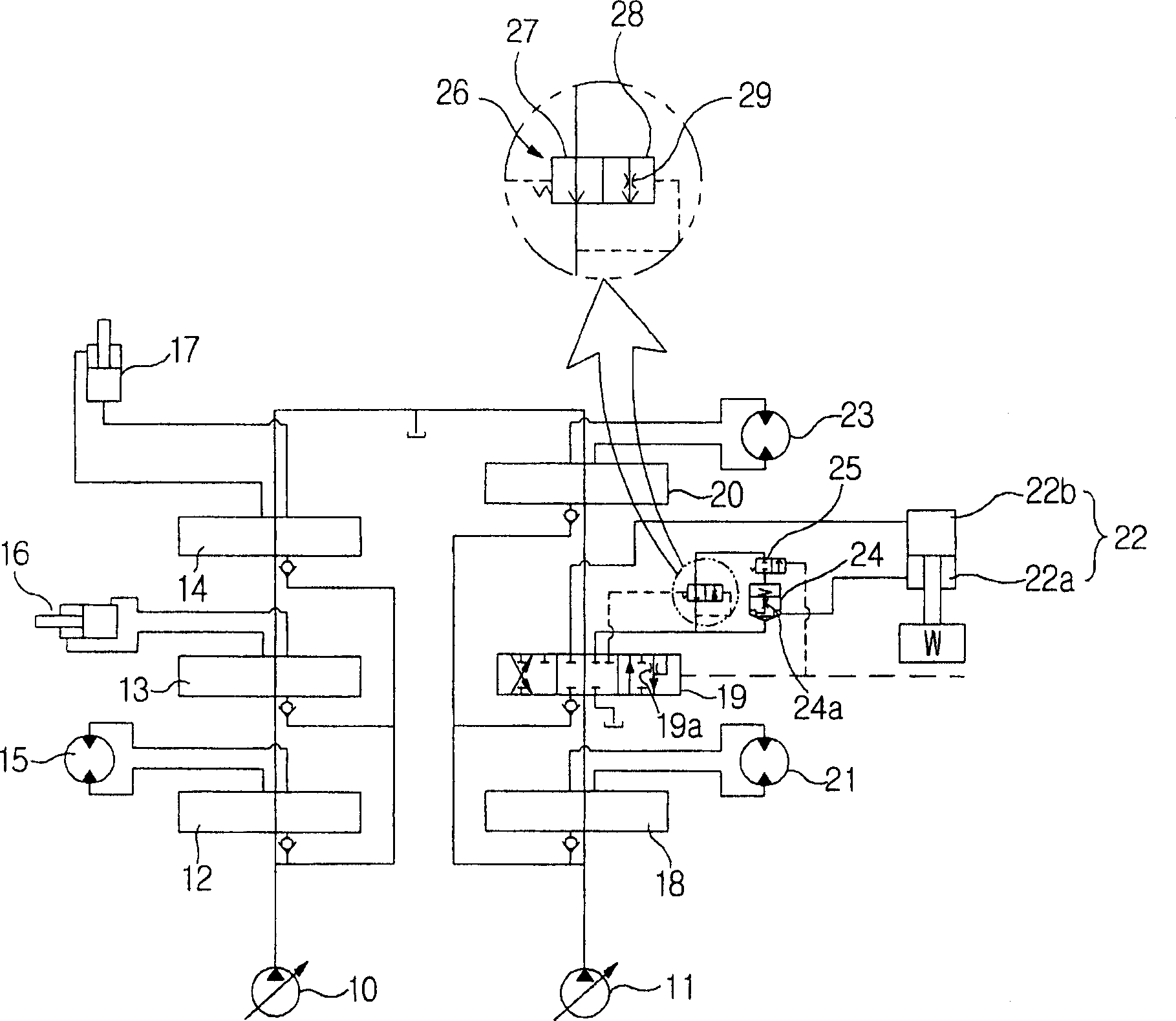

[0033] refer to image 3 , preferred embodiments of the present invention will now be explained.

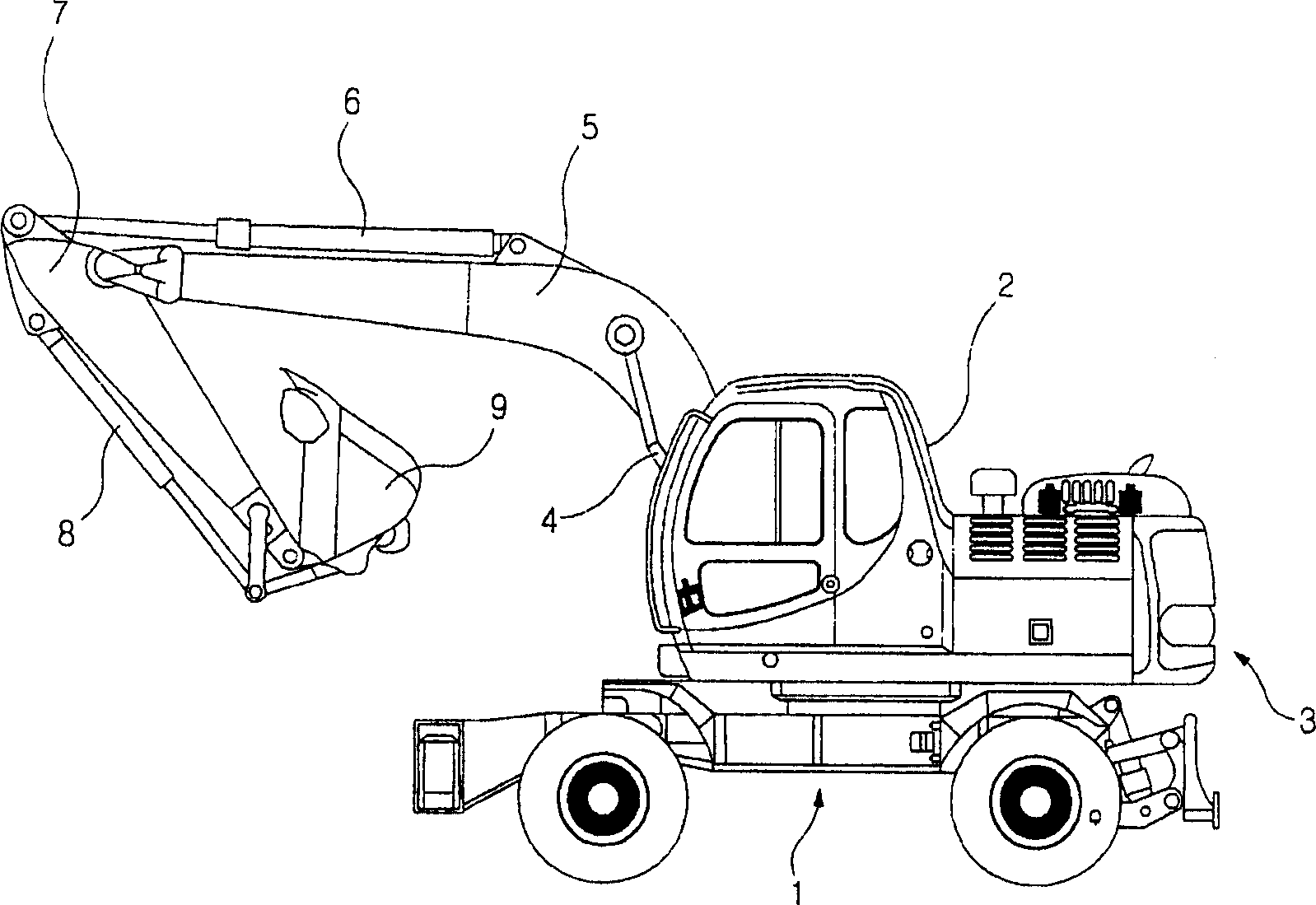

[0034] like image 3 As shown, the pressure compensating hydraulic circuit with lock valve according to the present invention includes: first and second variable displacement hydraulic pumps 10 and 11; mobile motor 15, bucket cylinder 16 and boom cylinder 17, which are respectively connected to the first variable displacement hydraulic pump 10 and hydraulic fluid is supplied to the control valves 12, 13 and 14 from the first hydraulic pump 10 when they are switched in response to a control signal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com