Induction motor

A technology of induction motors and coils, which can be applied to the shape/style/structure of magnetic circuit, electromechanical devices, and rotating parts of magnetic circuit, etc., and can solve the problems such as the increase of the end turning part 121

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Reference will now be made in detail to the preferred embodiments of the invention, examples of which are illustrated in the accompanying drawings.

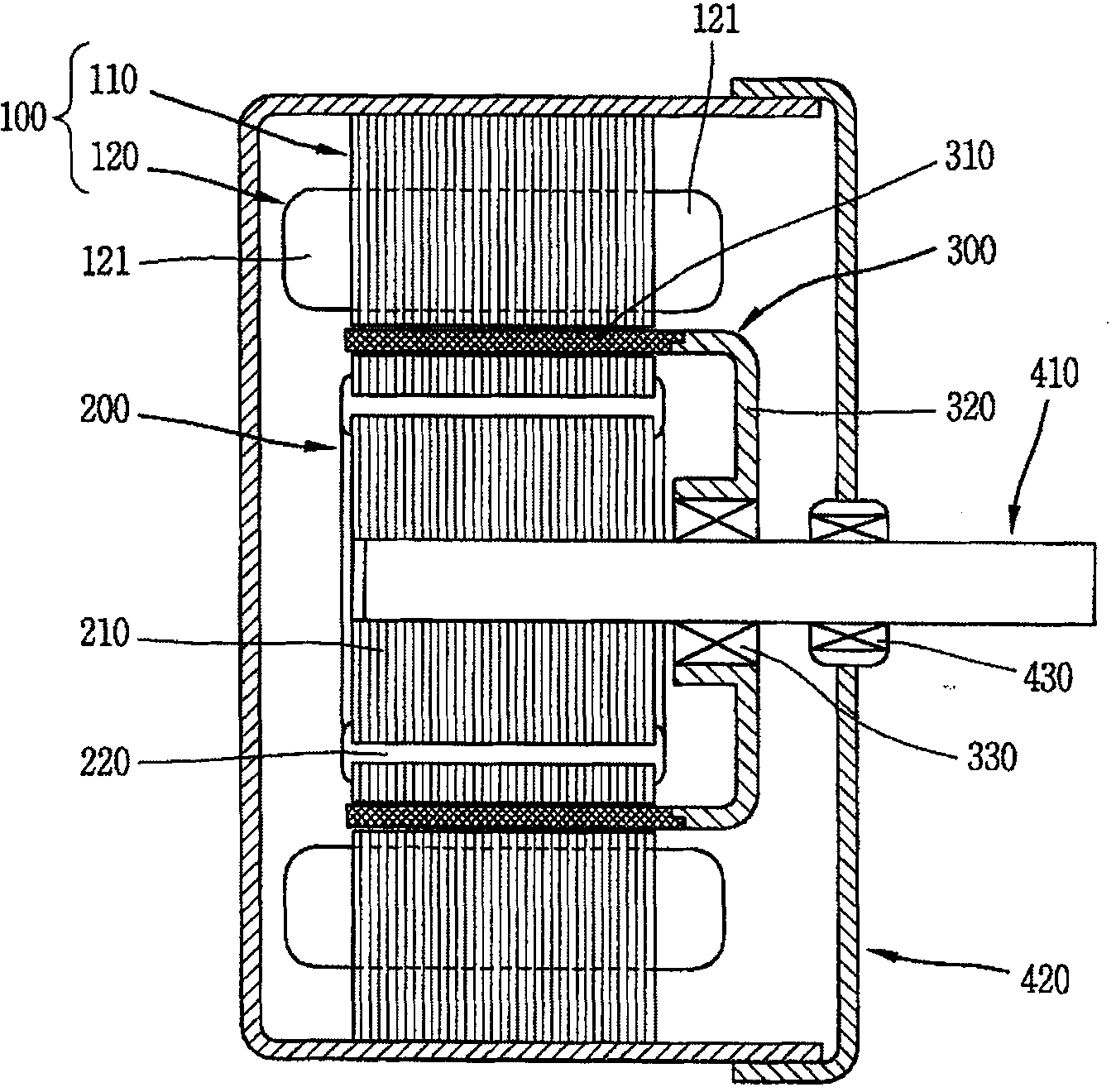

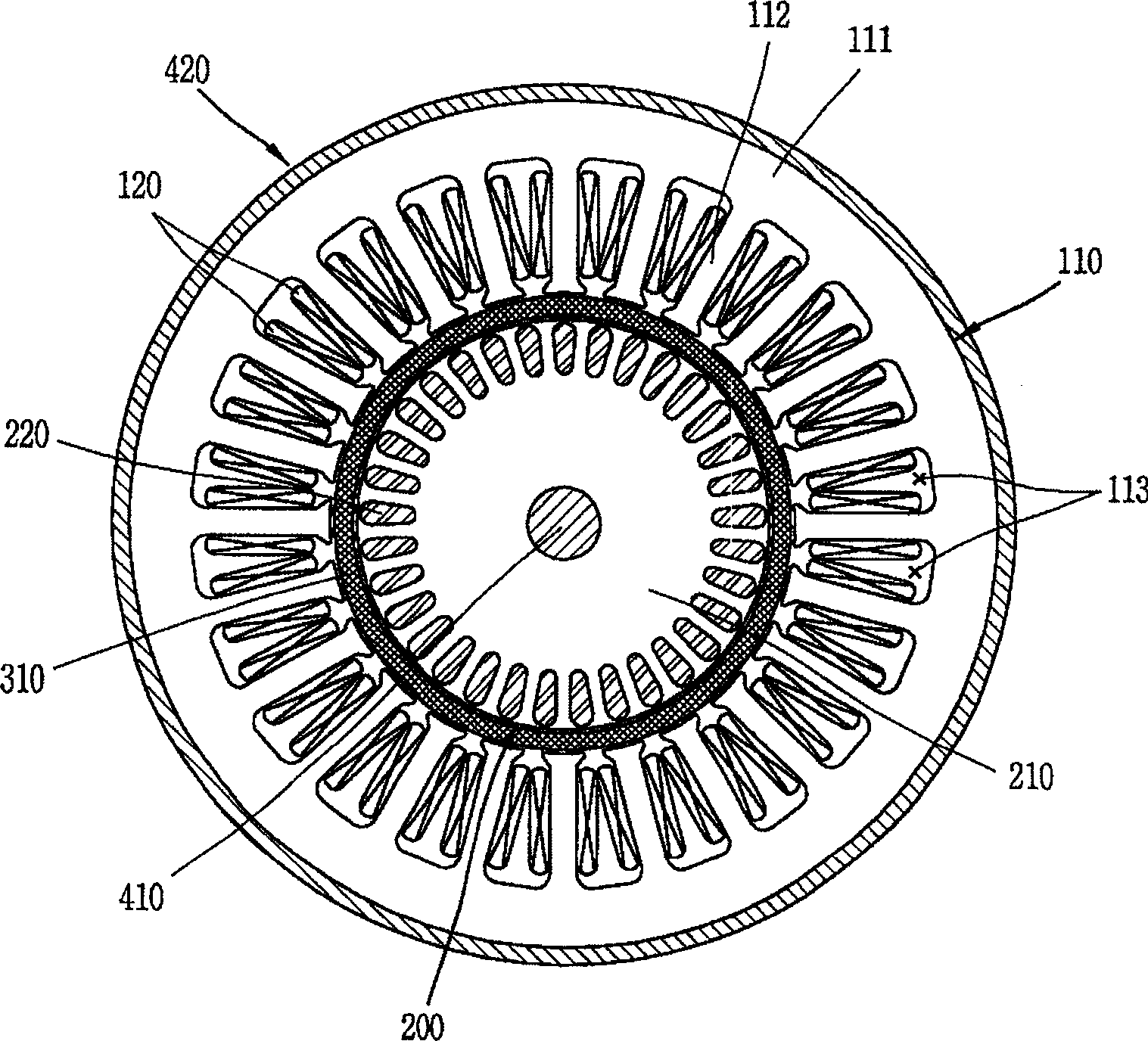

[0037] Figure 4 shows a front sectional view of an embodiment of an induction motor according to the invention, Figure 5 It is a side sectional view of the induction motor.

[0038] As shown in the figure, first, the induction motor is provided with a stator including a stator core 510, a main winding coil 520 wound on the stator core 510, and an auxiliary winding coil 530 wound on the stator core (the auxiliary winding coil 530 smaller than the volume of the main winding coil 520 ), the main rotor 600 rotatably inserted into the stator 500 , and the sub-rotor 700 including the magnet 710 and rotatably inserted into the air gap between the stator 500 and the main rotor 600 .

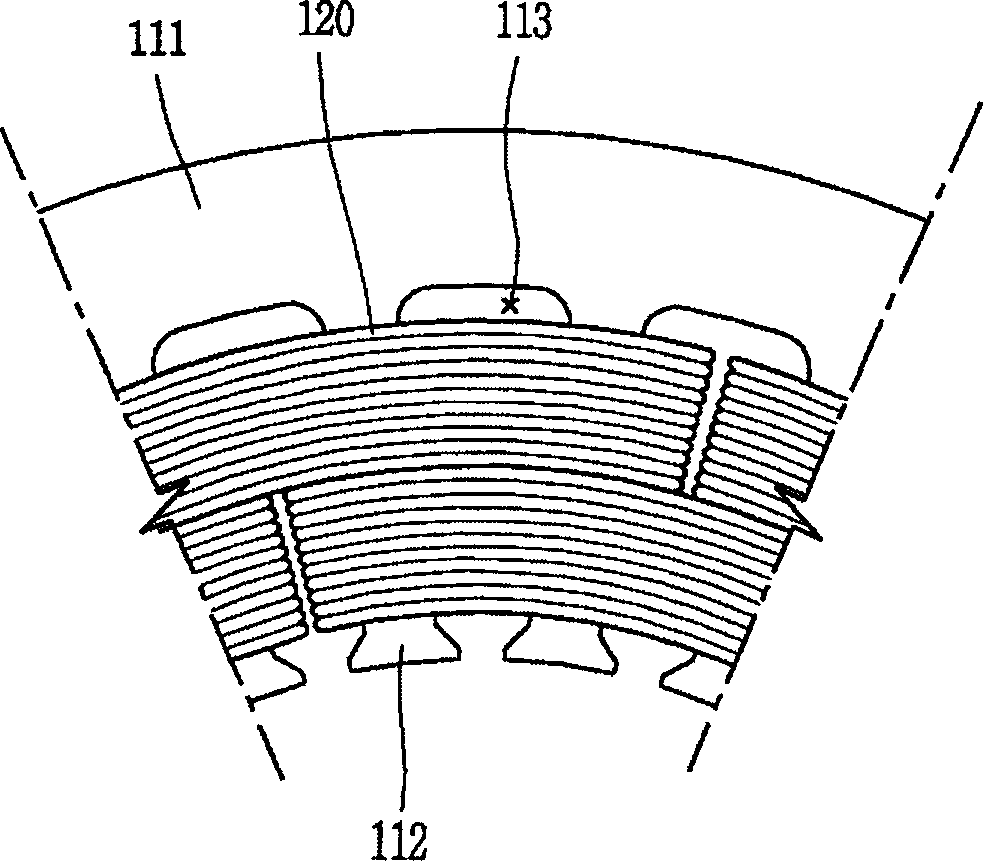

[0039] The stator core 510 includes: a yoke 511 formed in a ring shape having a certain width; and a plurality of teeth 512 formed on an inner c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com