Self-absorption type zero-clearance shear-flow superfine grinding machine

An ultra-fine pulverizer with no gap technology, which is applied in the direction of grain processing, etc., to achieve the effect of novel and reasonable structure and improved crushing production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

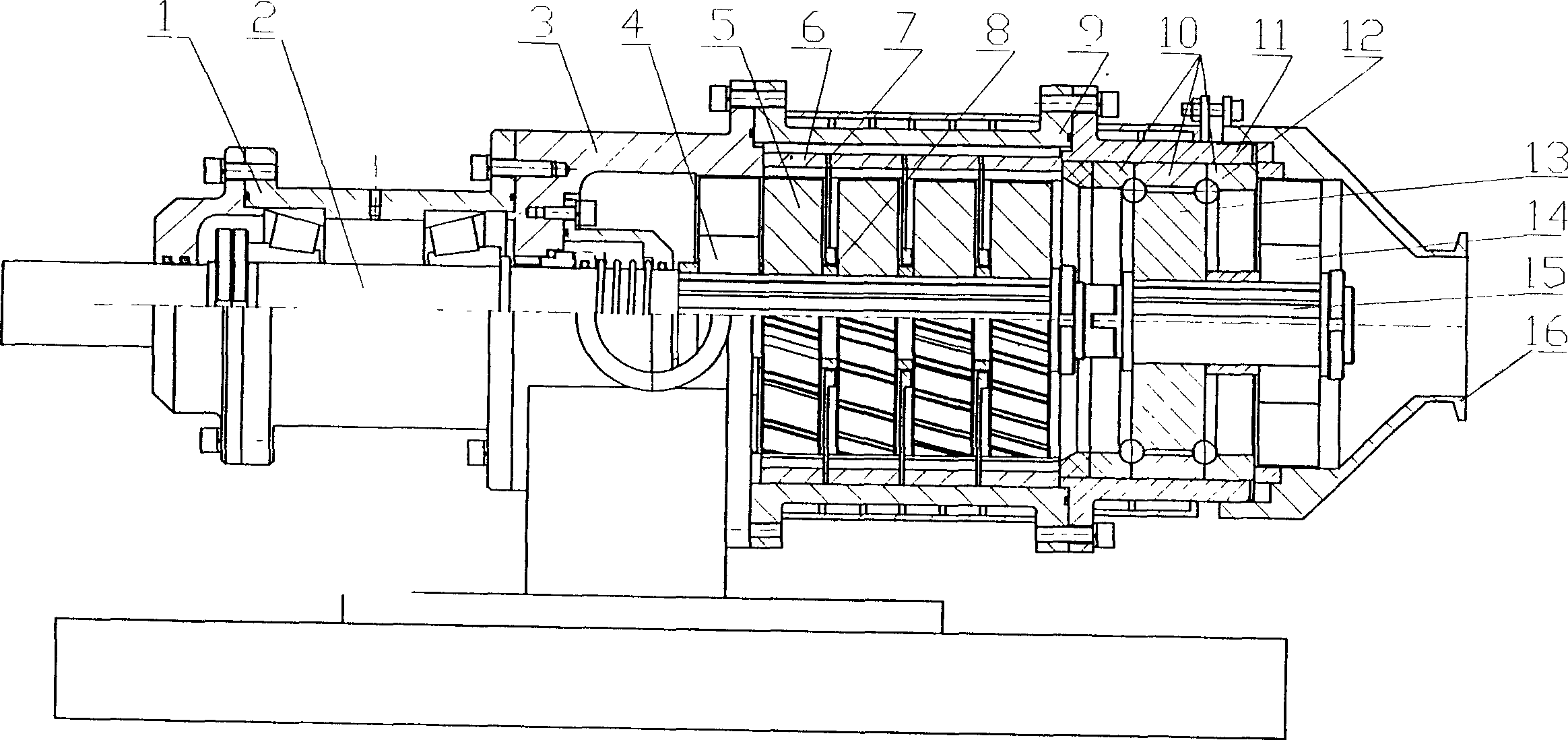

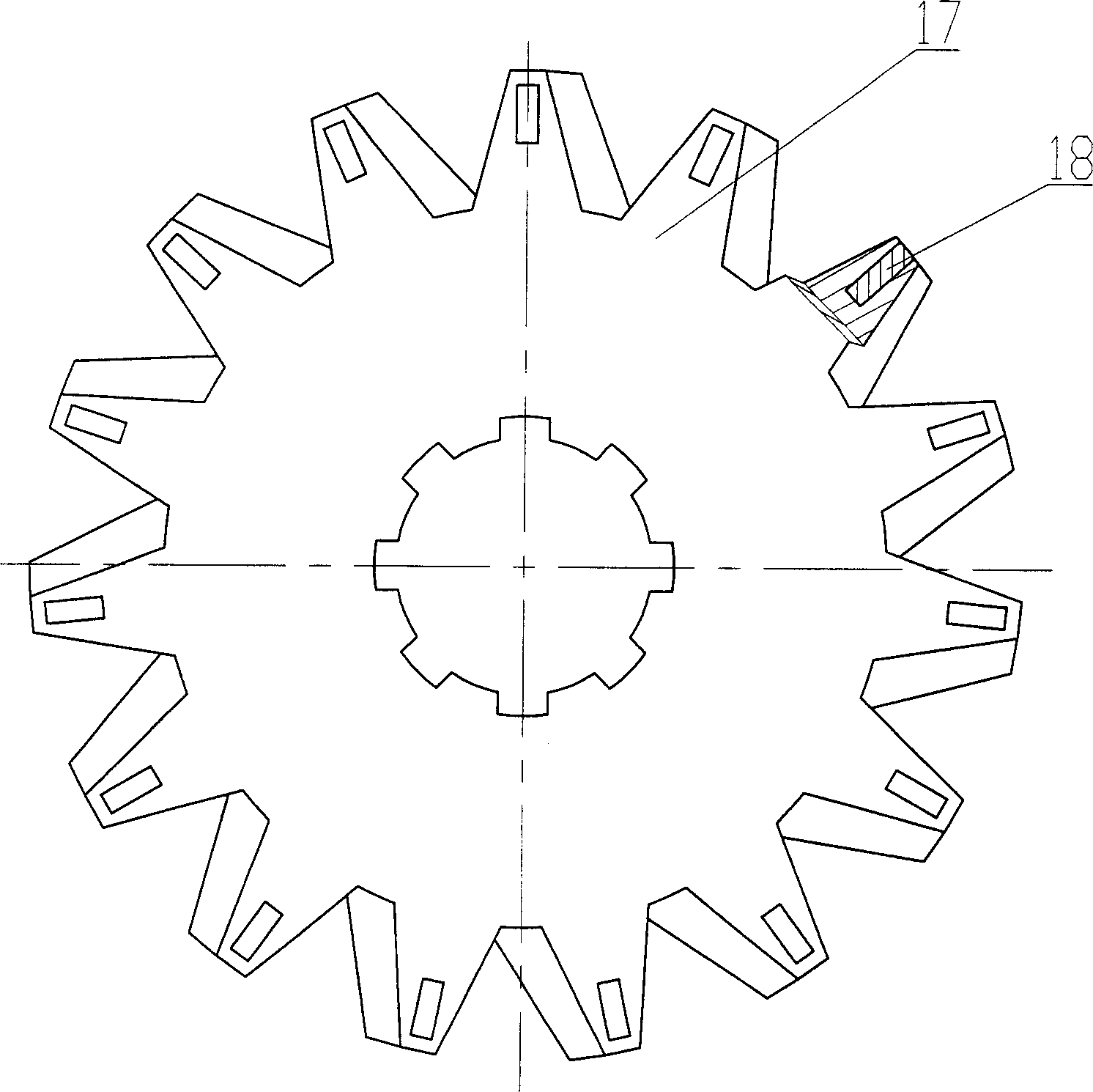

[0012] A self-priming non-gap shearing fluid ultrafine pulverizer, a feed chamber 3 is installed on the machine base, a bearing seat 1 is installed in front of the feed chamber 3, and a main shaft 2 is installed in the bearing seat 1. The feed chamber 3 is equipped with an axial flow impeller 4 . Housing 9 is installed behind feeding chamber 3, and eccentric stator 6 is installed in housing 9, and rotor 5 is installed in eccentric stator 6, and spacer 8 is installed between multi-channel rotors 5, and current limiting splint 7 is installed outside spacer 8. The housing 9 is equipped with an arc-slotted stator fixing sleeve 11, and the arc-slotted stator fixing sleeve 11 is equipped with an arc-slotted stator 10, and the arc-slotted stator 10 is equipped with an arc-slotted rotor 13, between the arc-slotted stator 10 and the arc-slotted rotor 13 The ball 12 is installed between, and the band arc groove rotor 13 is contained on the small shaft 15, and the axial flow impeller 14 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com