Resonance circuit output characteristic controlling method

A resonant circuit and output characteristic technology, applied in the field of resonant circuit output characteristic control, can solve problems such as weak voltage regulation capability, affecting module performance, and inability to improve control defects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

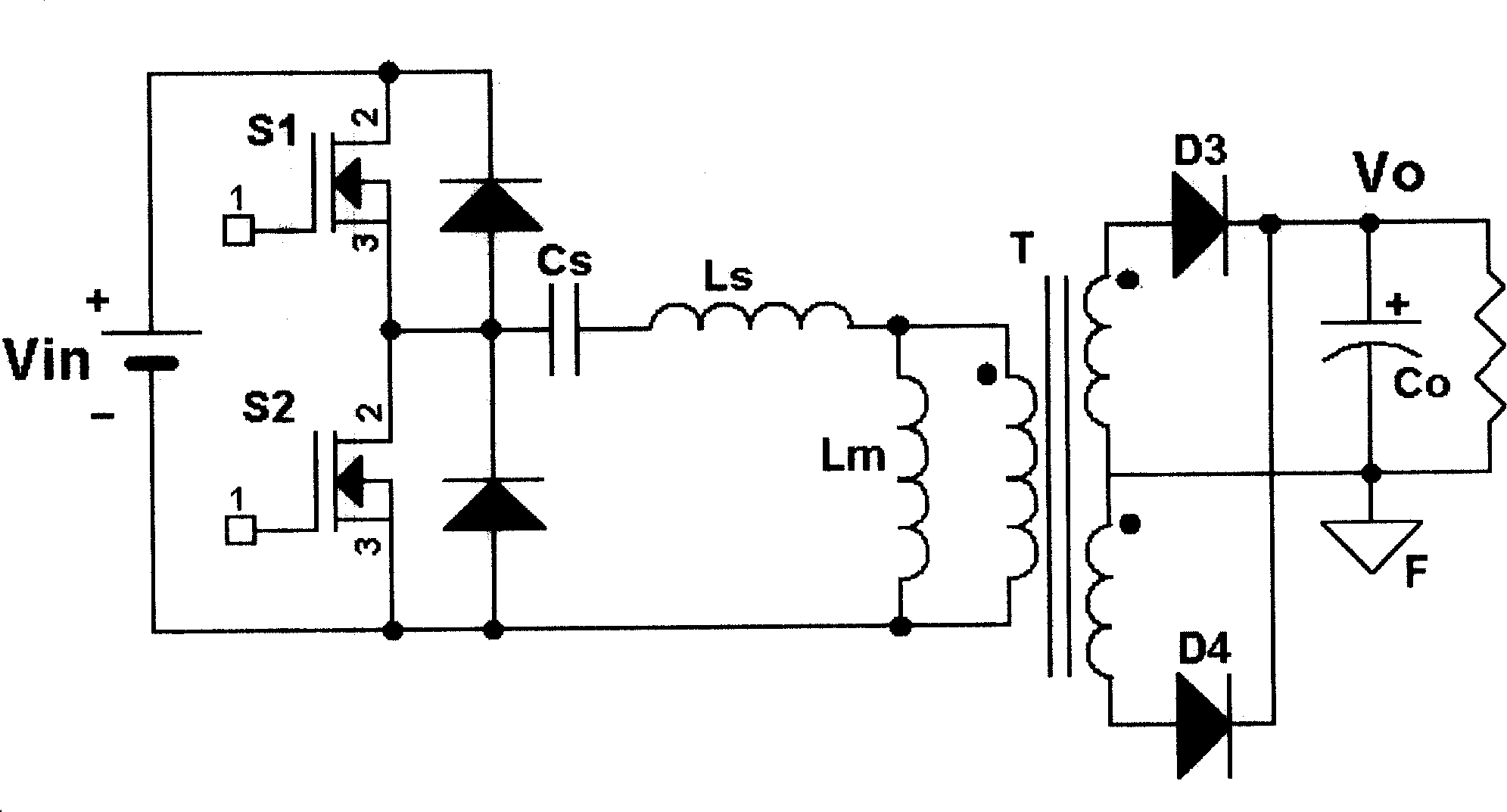

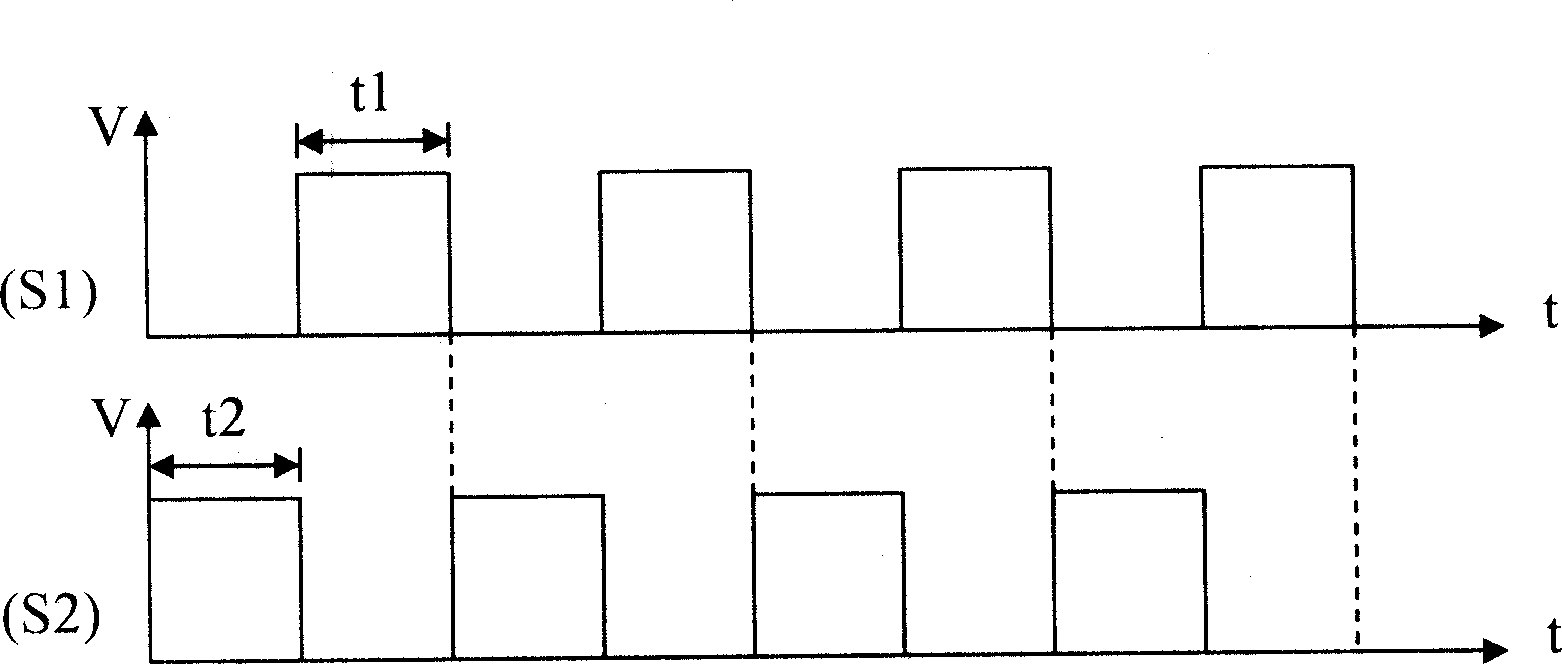

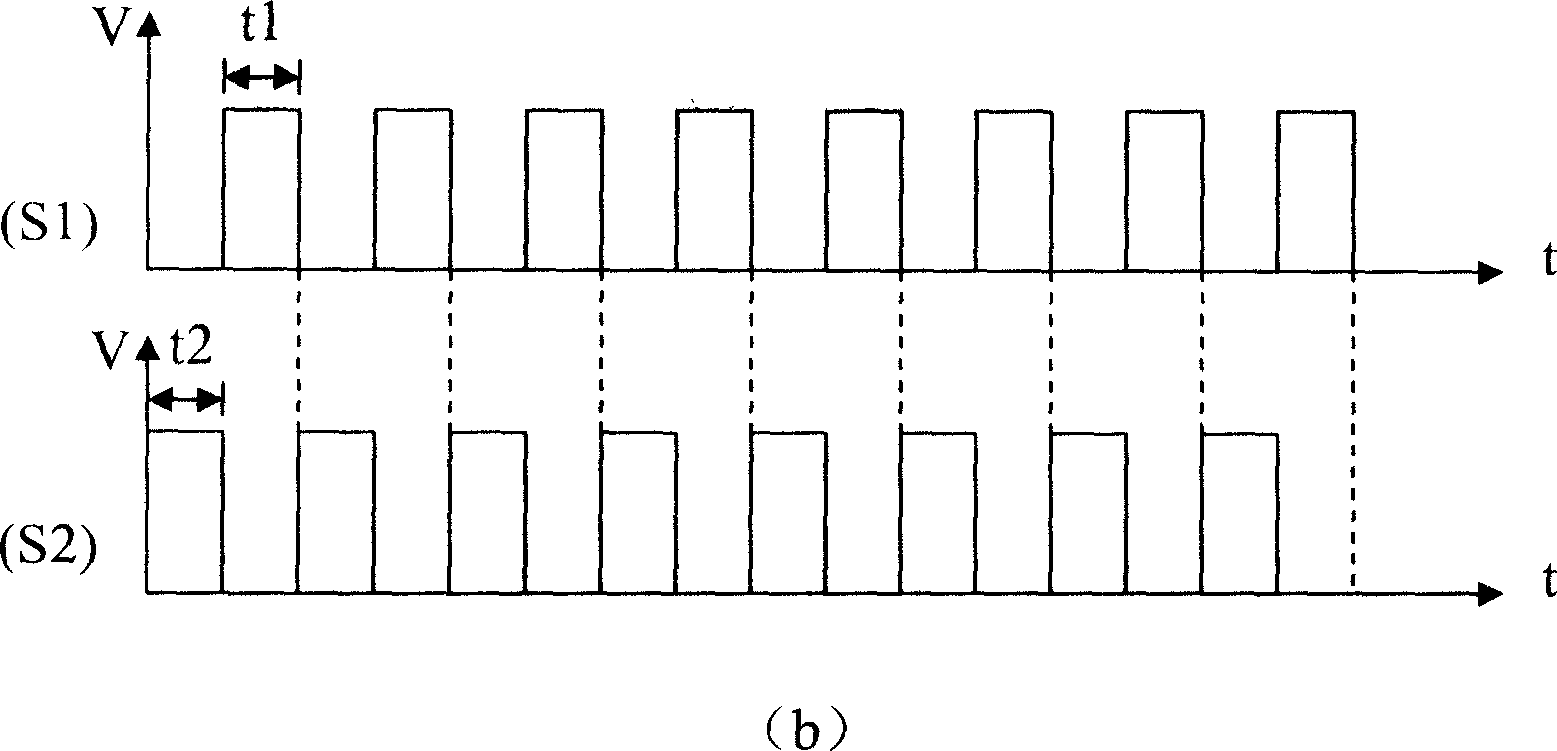

[0019] A method for controlling the output characteristics of a resonant circuit is to adjust the output voltage by comprehensively using PFM and PWM control modes to control two sets of switch tubes of the circuit, so as to improve the control of the voltage output characteristics of the resonant circuit.

[0020] still with figure 1 Take the half-bridge LLC resonant circuit in the example, Figure 4 Curve A in the figure is a schematic diagram of the characteristic curve of output voltage Vo and frequency f with a duty cycle of 50% using a separate PFM control method; Figure 4 Curves B1, B2, and B3 in the figure are schematic diagrams of the characteristic curves of the output voltage Vo and the duty cycle D when the switching frequency is 120kHz, 210kHz, and 290kHz, respectively, using a separate PWM control mode; Figure 4 The curves C1, C2, and C3 in the figure are schematic diagrams of the characteristic curves of output voltage Vo, duty cycle D, and frequency f in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com