Process for making integral elastic supports and support obtainable by said process

An elastic support and integral technology, applied in the field of support and human body support, can solve problems such as defects, affecting the performance of the completed saddle, connecting parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

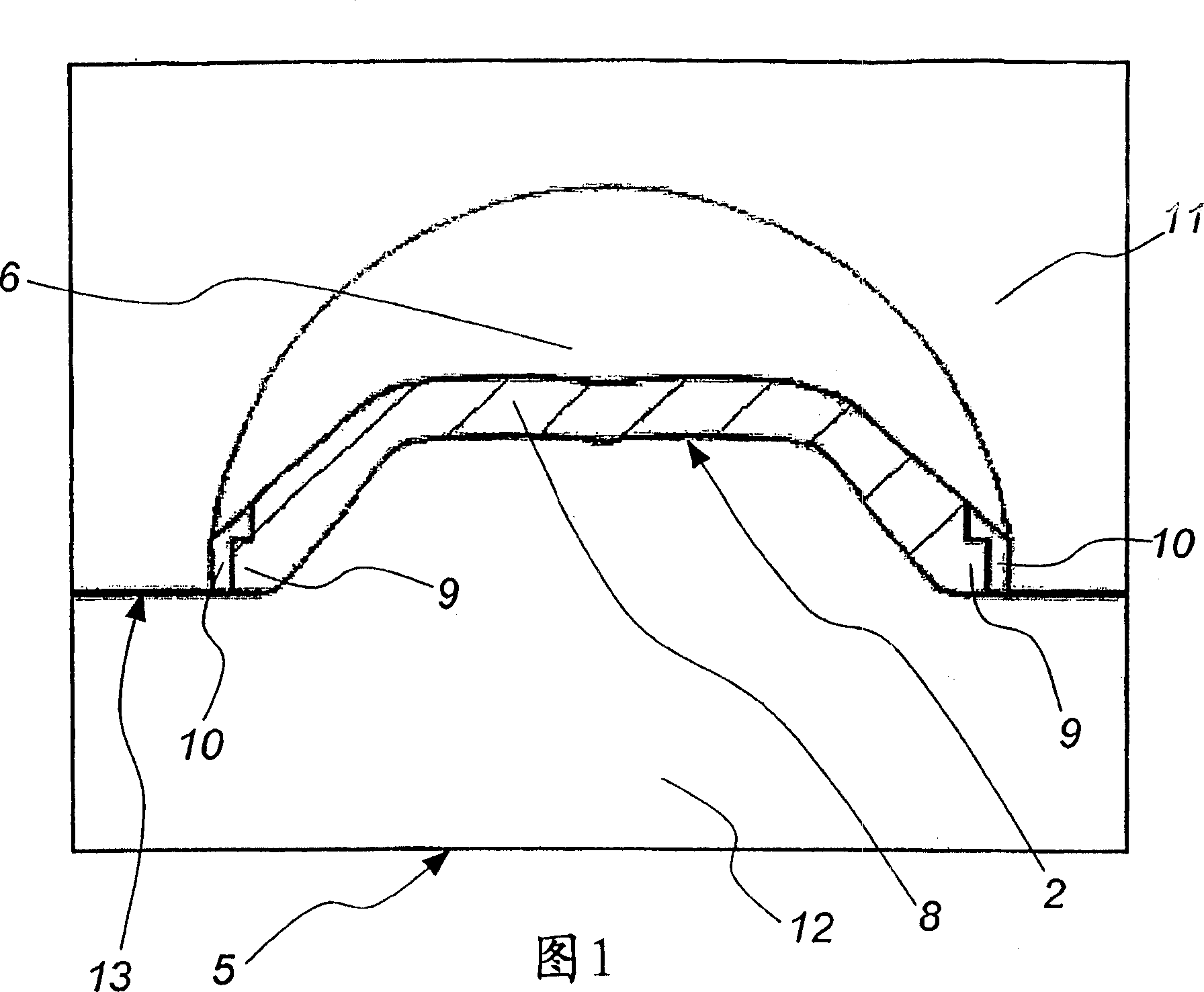

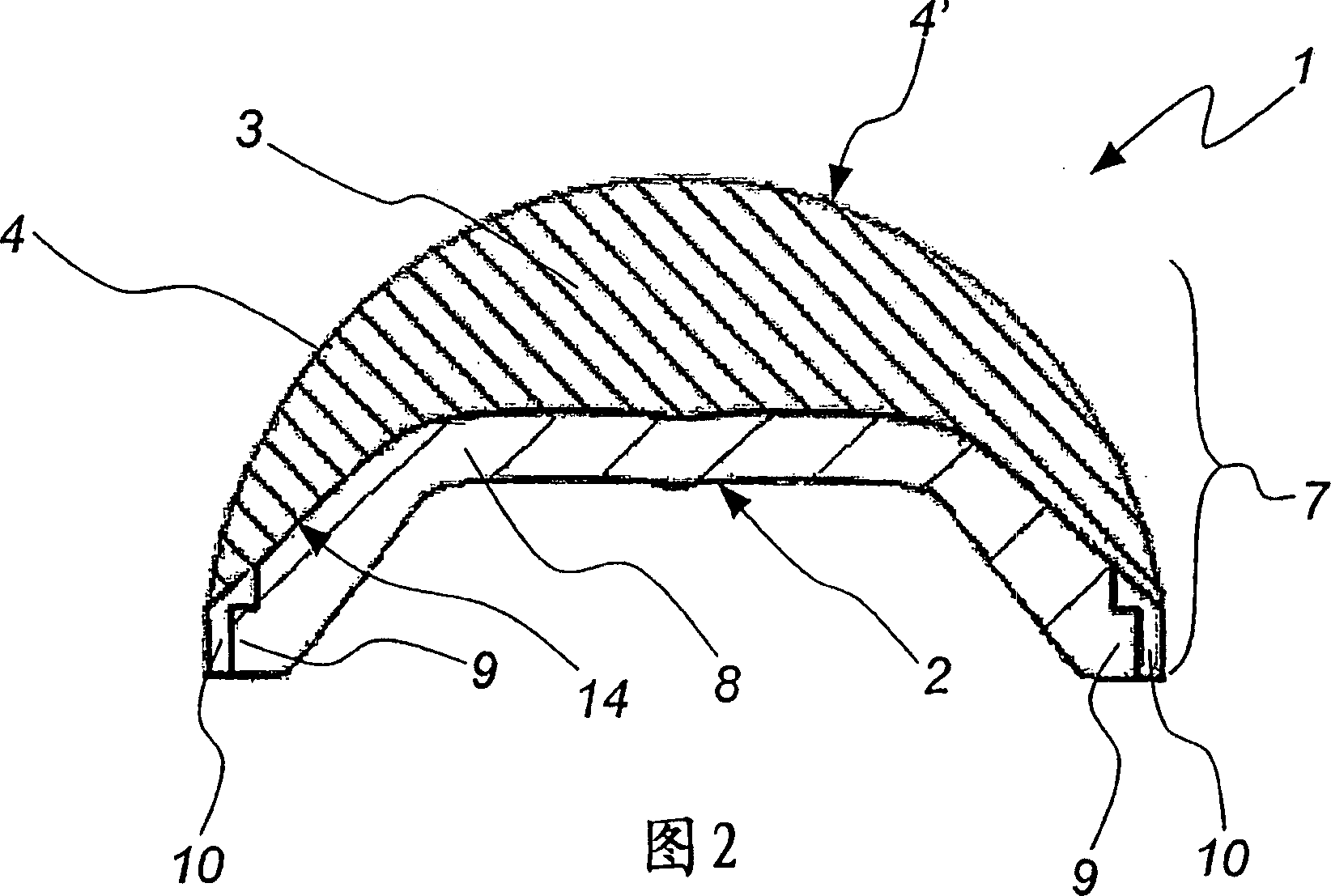

[0025] Specifically referring to the above drawings, the method for making an integral elastic support according to the present invention will be described. The overall elastic support is indicated by the numeral 1 as a whole. Various supports 1, such as seats, seat backs, armrests, saddles and seats for bicycles and similar vehicles, can be obtained in the manner described below.

[0026] In more detail, each support 1 comprises a substantially rigid or semi-rigid shell 2 and at least one layer 3 of elastic filler. A sheath 4 designed to be accessible to the user may be provided. The cover 4 defines a contact surface 4' for the user. Alternatively, the padding layer 3 with a suitably finished surface may directly define the user's contact surface 4'.

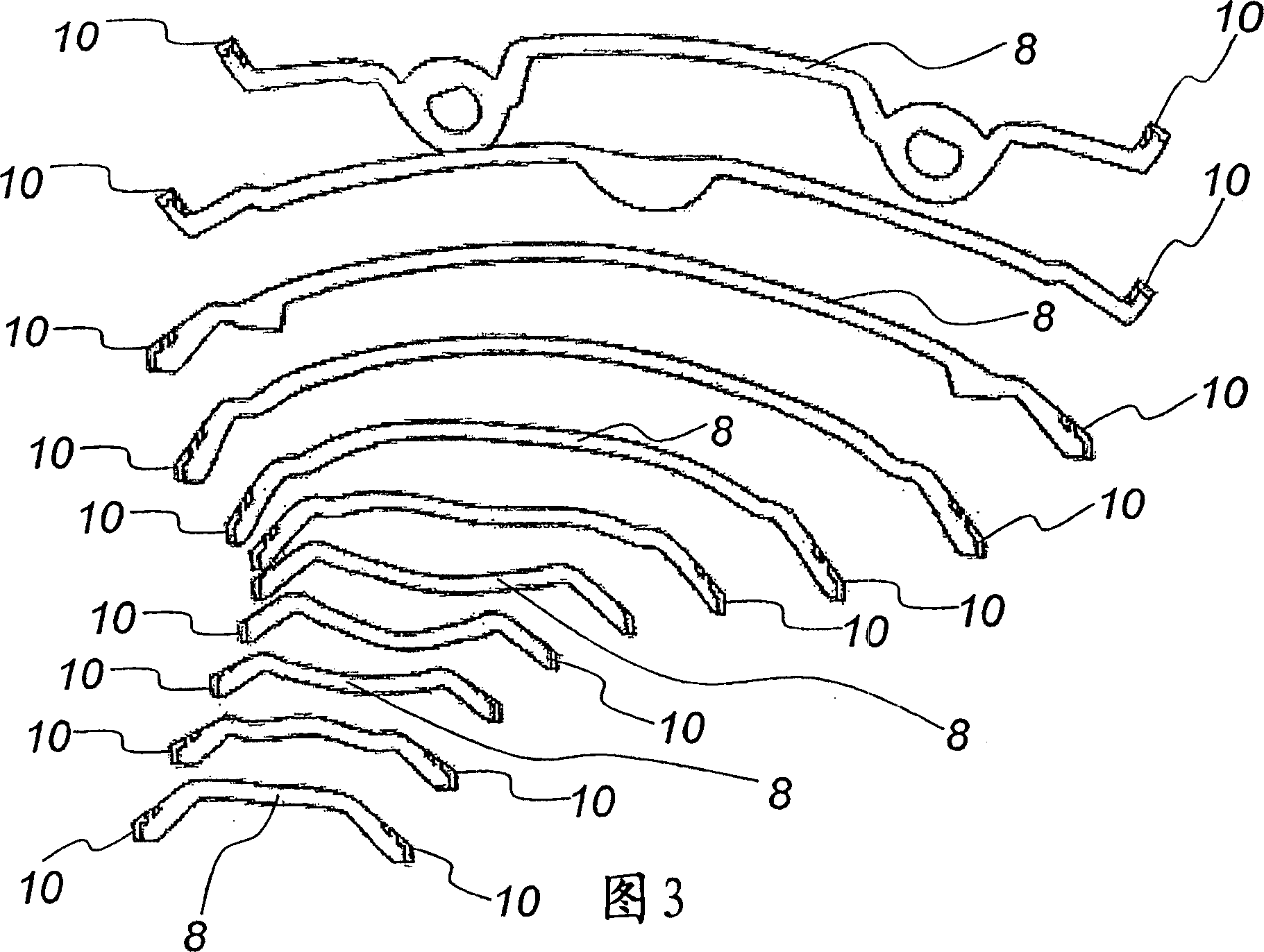

[0027] The method of the invention comprises a first step a) forming a casing 2 having a predetermined shape and structure. In a second step b), a model 5 is created for forming the filler layer 3 on the shell 2 . For this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com