Pneumatic tire for heavy vehicle

A technology of pneumatic tires and tire shoulders, applied in heavy tires, tire parts, tire treads/tread patterns, etc., and can solve problems such as abnormal wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

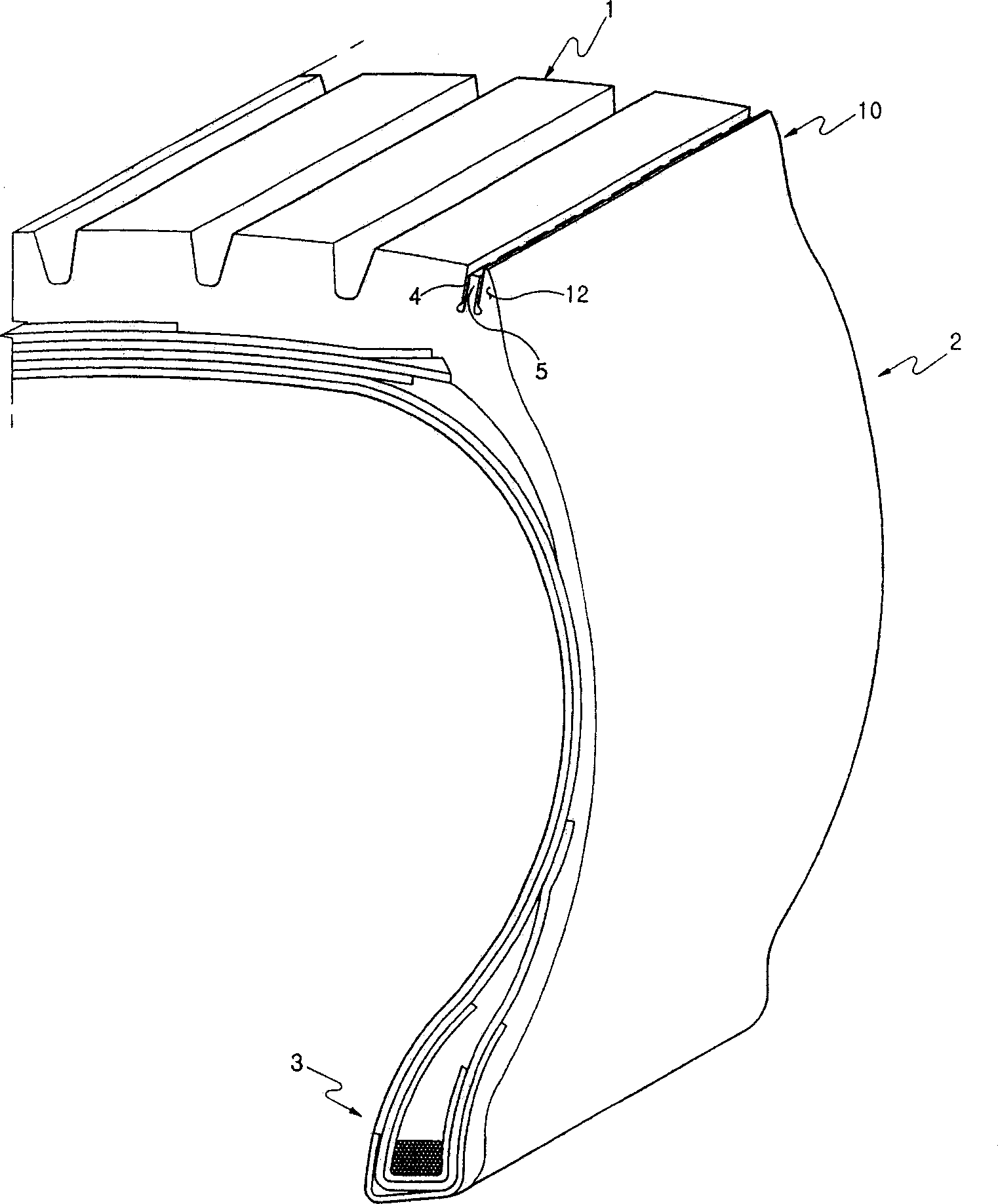

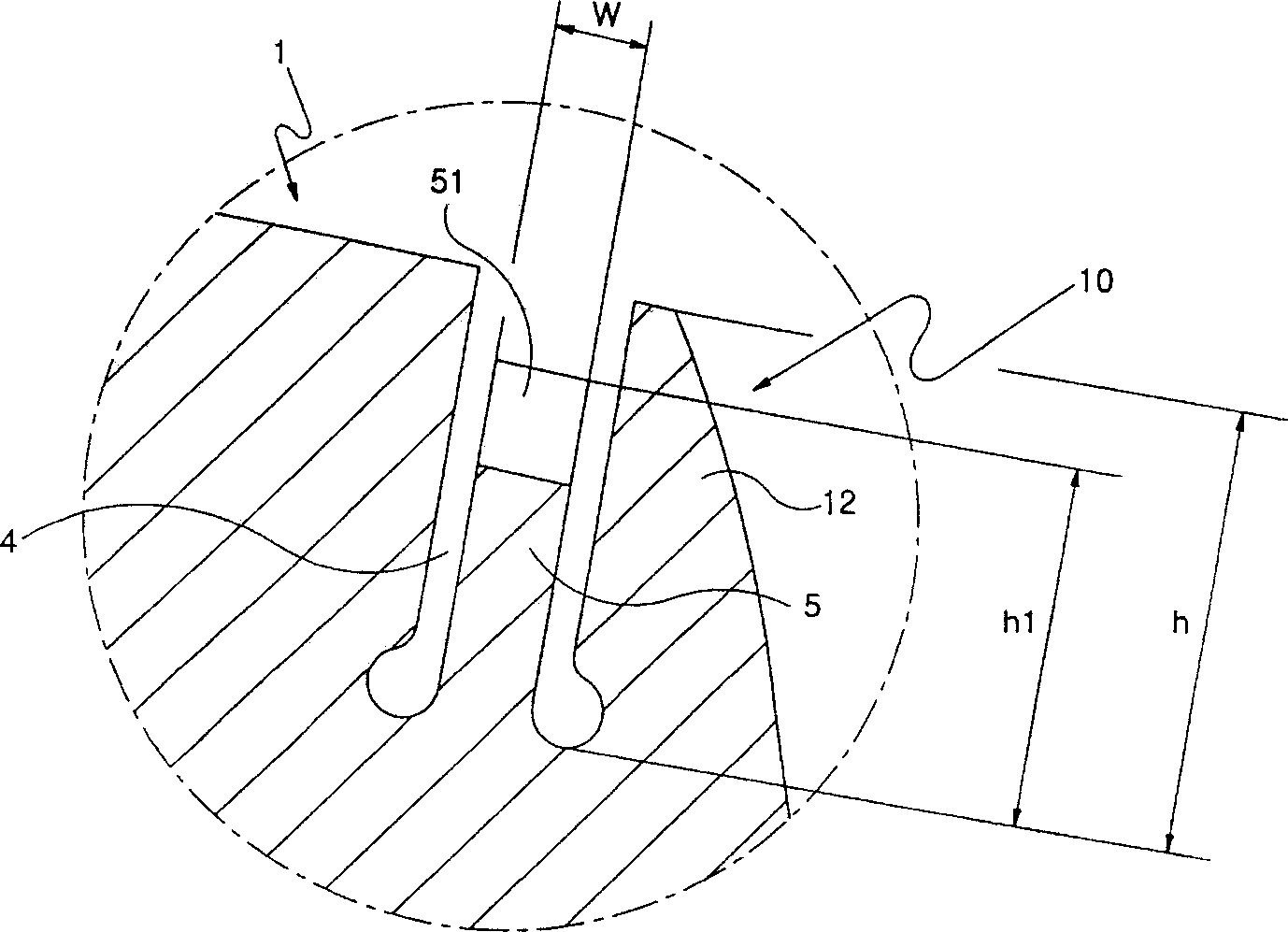

[0016] figure 1 Shown is a partial perspective view of the tire of the present invention, figure 2 Shown is a partial enlarged sectional view of the main part of the present invention.

[0017] Such as figure 1 and figure 2 As shown, the pneumatic tire for load bearing of the present invention includes a tread portion 1, a sidewall portion 2 and a bead portion 3, and a decoupling groove 4 is formed on the shoulder portion 10 of the tread portion 1, wherein, in the decoupling A sacrificial rib 5 is formed at the center inside the groove 4 .

[0018] The height h1 of the sacrificial rib 5 is lower than the height h of the rib 12 formed at the outermost end, and the height h1 of the sacrificial rib 5 is 30-90% of the height h of the rib 12 formed at the outermost end.

[0019] In addition, a plurality of grooves 51 at equal intervals...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com