Method for pre-vulcanizing circular tread capable of regulating circumference

A tread and annular technology is applied in the field of manufacturing retreaded tire treads to achieve the effects of improving wear resistance, prolonging service life and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

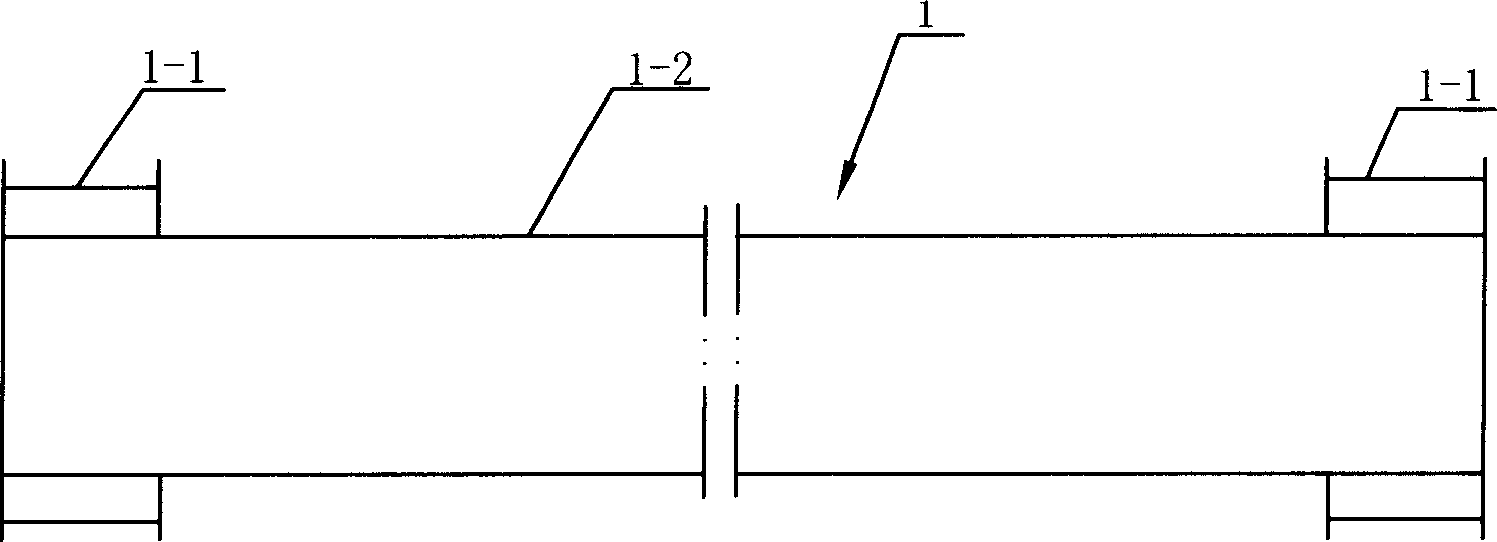

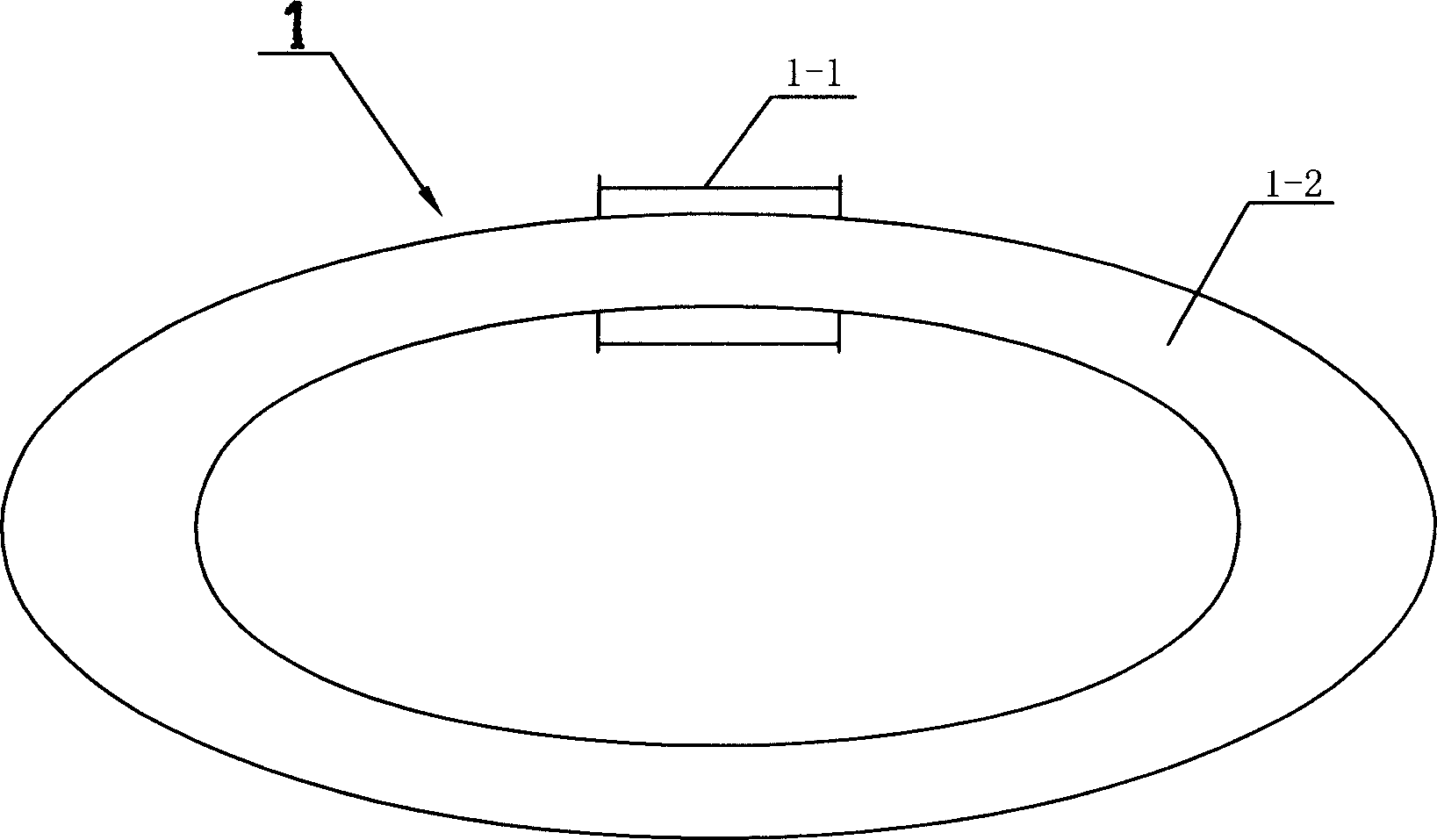

[0020] (1). The tread 1 is made into strips, the length is selected according to the requirements of the specification, vulcanized by a flat vulcanizer, and semi-vulcanized at 1-1 of the lap joints at both ends, the degree of semi-vulcanization is 30% of that of normal vulcanization. Between 70%, water is passed at both ends of the vulcanization model at 1-1 of the lap joint, and the water-passing interval is 200-500mm, so that the vulcanization temperature is 10-20°C lower than the normal vulcanization temperature, and the rest of the tread is 1-2 Bits are vulcanized.

[0021] (2). After the other parts 1-2 of the tread are being vulcanized, the semi-vulcanized overlapping surface 1-1 is roughened first, and the glue is painted, and after volatilization, supplementary vulcanization is carried out. The overlapping surface 1-1 is annularly vulcanized to achieve positive vulcanization.

[0022] In the above process method, the vulcanization pressure is 80-150kg / cm 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com