Roller type electric brush module of regulating transformer

A regulating transformer and roller type technology, applied in the field of regulating transformers, can solve the problems of high cost, troublesome manufacturing, large volume, etc., and achieve the effects of low cost, improved performance and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

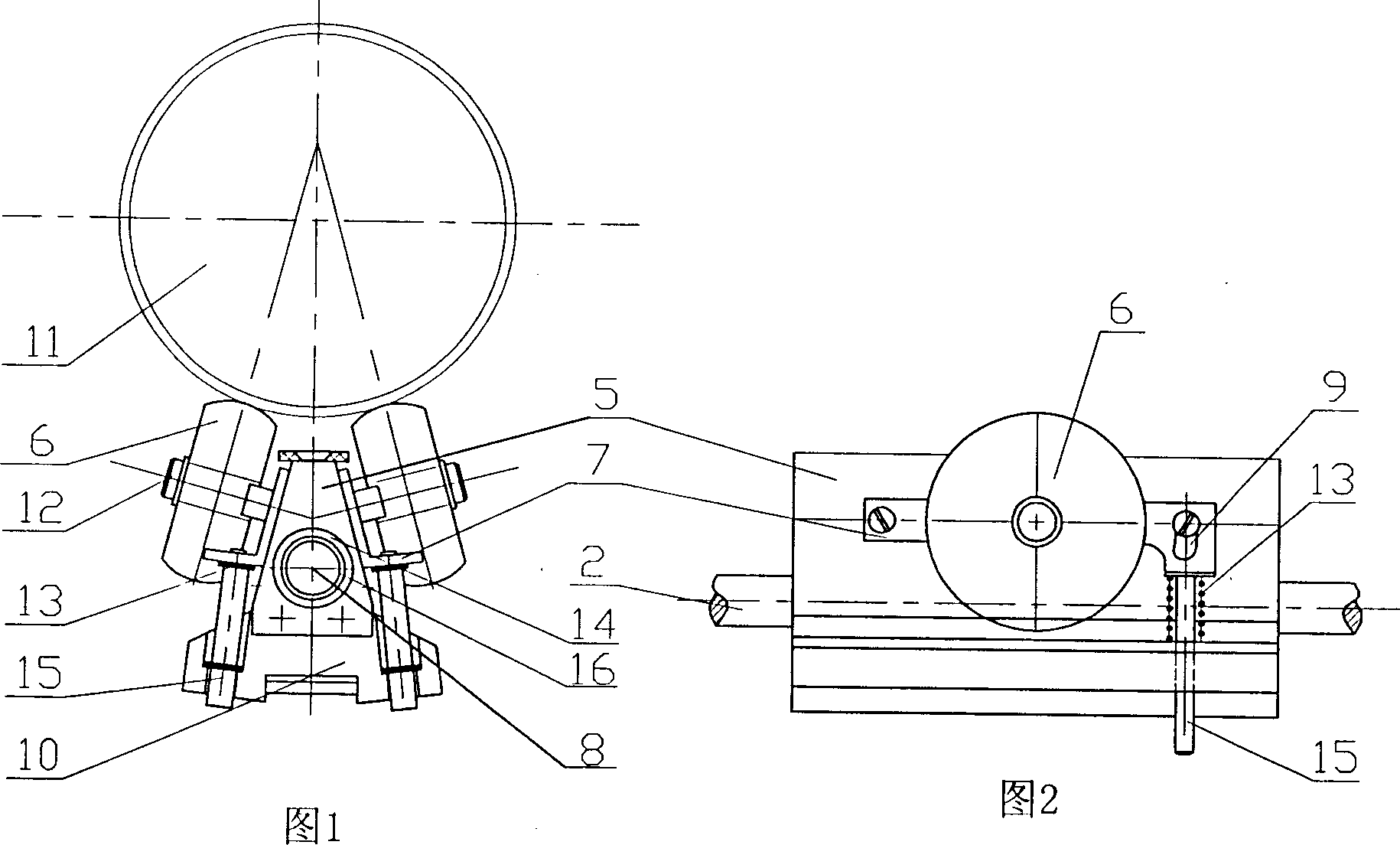

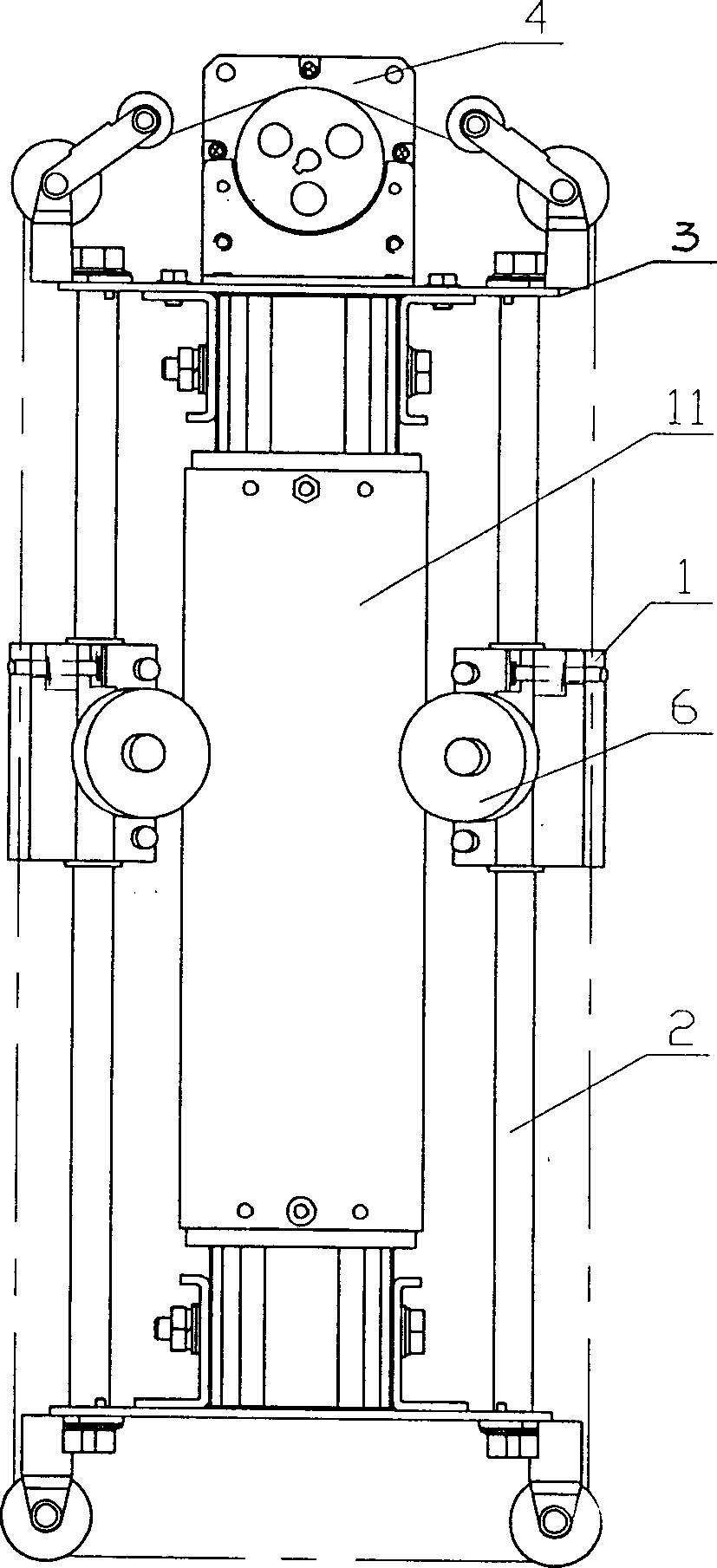

[0011] As shown in Figures 1 and 2, the roller brush assembly 1 of this embodiment includes a roller brush 6 and a slider 5. Sliding plates 7 are installed on the slopes on both sides of the slider 5, and one end of the sliding plate 7 is positioned on the slider 5. On one side of the slope, the other end of the slide plate 7 is positioned on the other side of the slide block slope through the keyway 9 provided on the slide block slope and moves along the keyway 9 of the slider 5 under the action of the pressure spring 13, and the wheel shaft 12 is fixed on the slide plate 7 , The roller brush 6 is placed on the wheel shaft 12 and can rotate around the wheel shaft. In order to enable the pressure spring 13 to perform better adjustment and guiding functions, in this embodiment, the side of the slider 5 with a keyway is provided with a guide shaft 15, the pressure spring 13 is sleeved on the guide shaft 15, and the guide shaft 15 is positioned on the slider seat 10 , the slide p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com