Oscillating piston engine

A technology of piston engine and rotary motion, which is applied in the direction of rotary piston engine, swing piston engine, swing piston engine, etc., and can solve problems such as incomplete elimination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

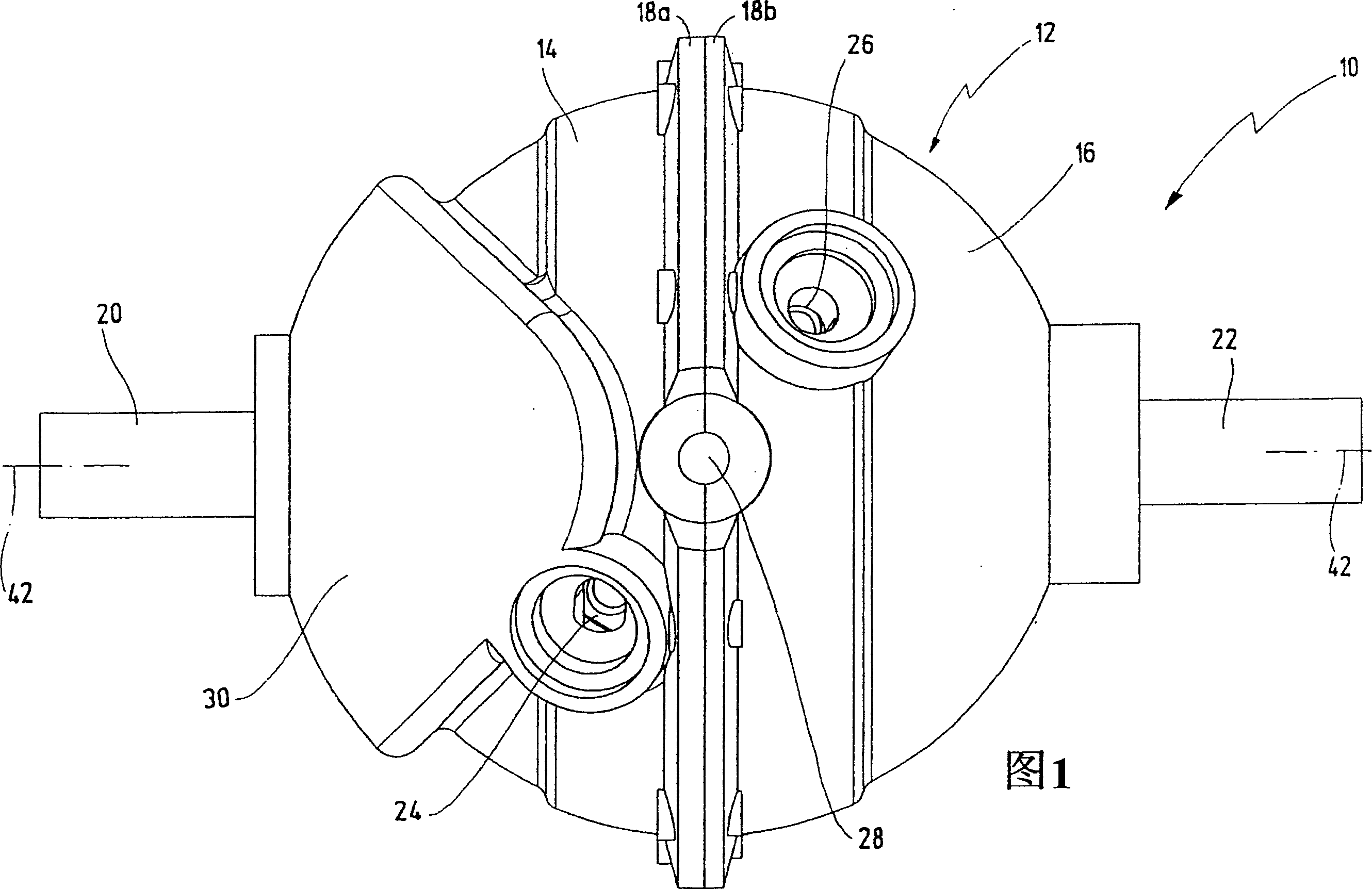

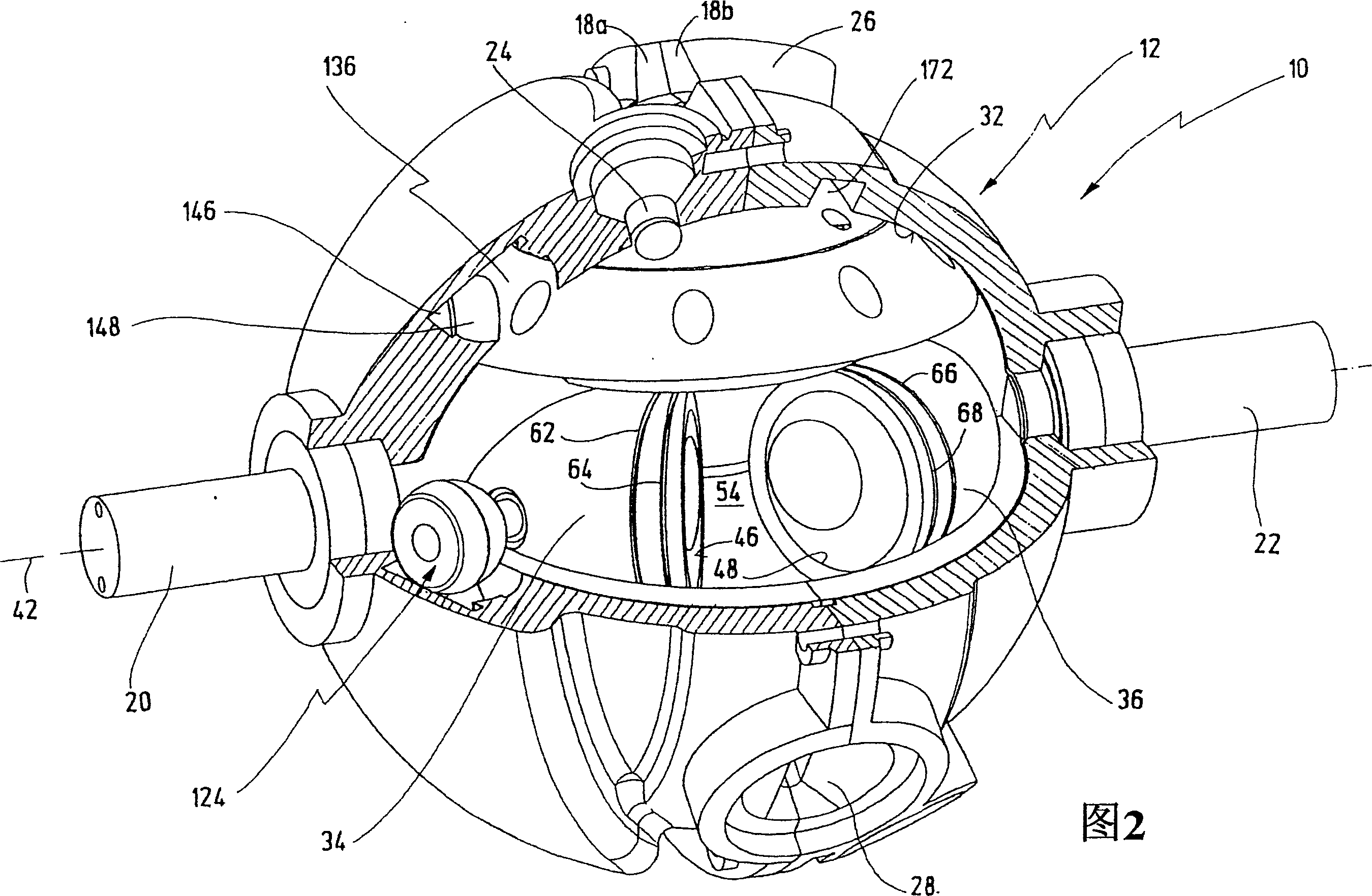

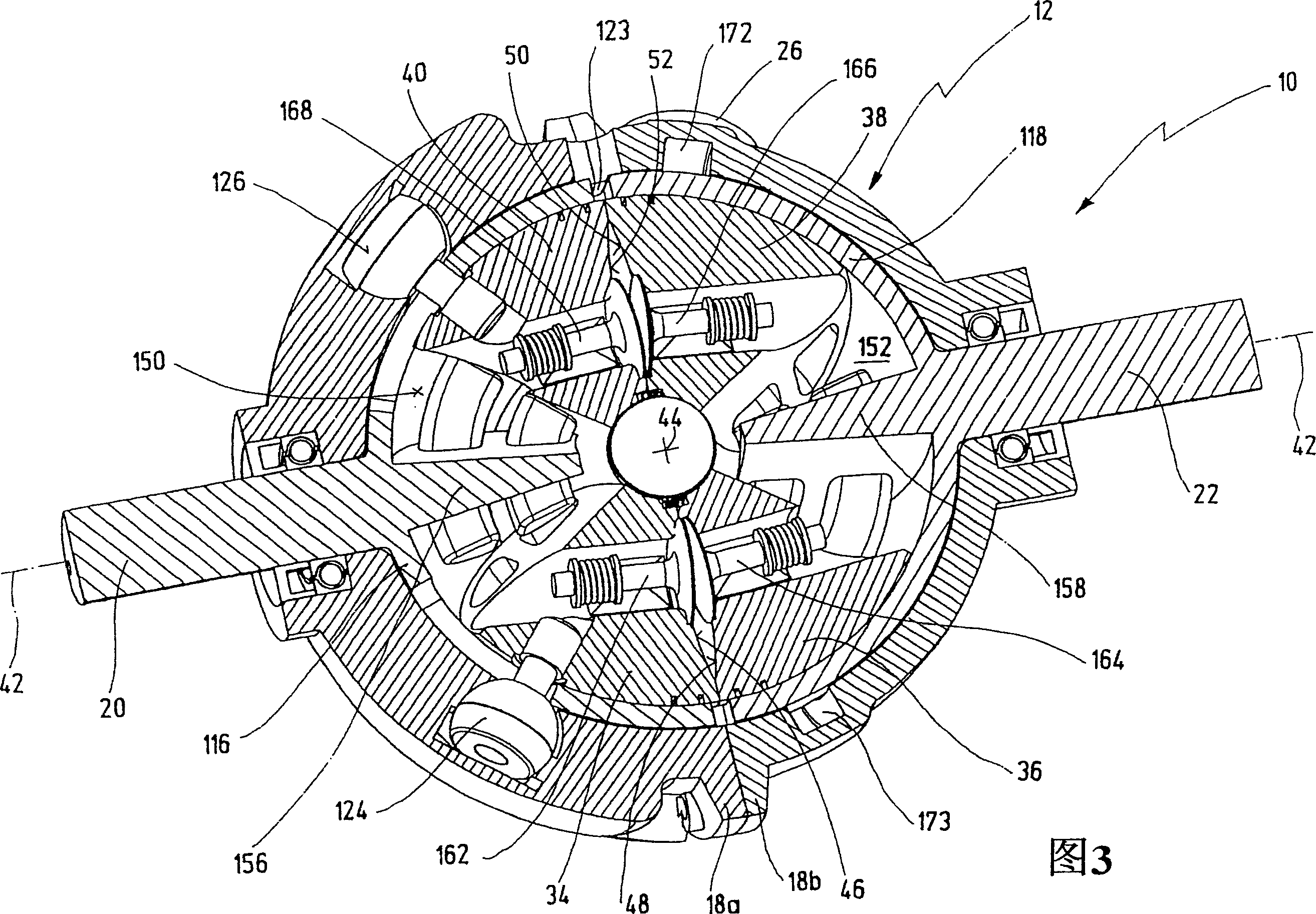

[0066] Figures 1-5, 8, 10 and 11 each show in general view a rotary piston engine having the common reference numeral 10. 6 and 7 and 9 and 12 show further details of the rotary piston engine 10 .

[0067] The rotary piston engine 10 is designed as an internal combustion engine in the present exemplary embodiment. However, in addition to the use of the rotary piston engine 10 as an internal combustion engine, it is also conceivable to slightly modify the rotary piston engine 10 for use as a compressor, a pump or the like.

[0068] The rotary piston engine 10 according to FIG. 1 has a substantially spherically symmetrical housing 12 . The housing 12 is composed of a housing part 14 and a housing part 16, which are releasably connected to one another via housing flanges 18a and 18b by screws.

[0069] The rotary piston engine 10 has a shaft 20 and a shaft 22 which protrude from the housing 12 on both sides. Instead of two shafts 20 and 22 it is also possible to have one shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com