Internal expanding type taper regulatable clamp

An internal expansion and taper technology, which is applied in the direction of manufacturing tools, thin wood chips, wood processing equipment, etc., can solve the problems of crushing, waste of bamboo inner ring materials, and the difficulty of rotary cutting machine rotary cutting, etc., to improve quality, Significant technical progress, full use of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

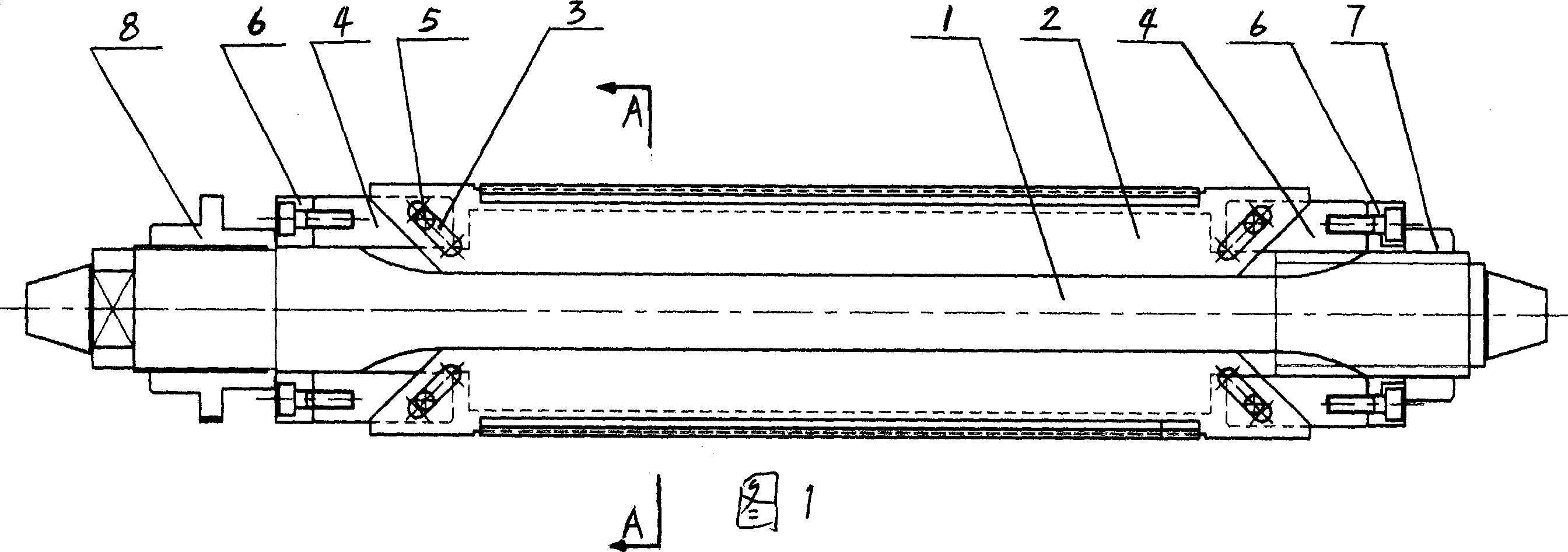

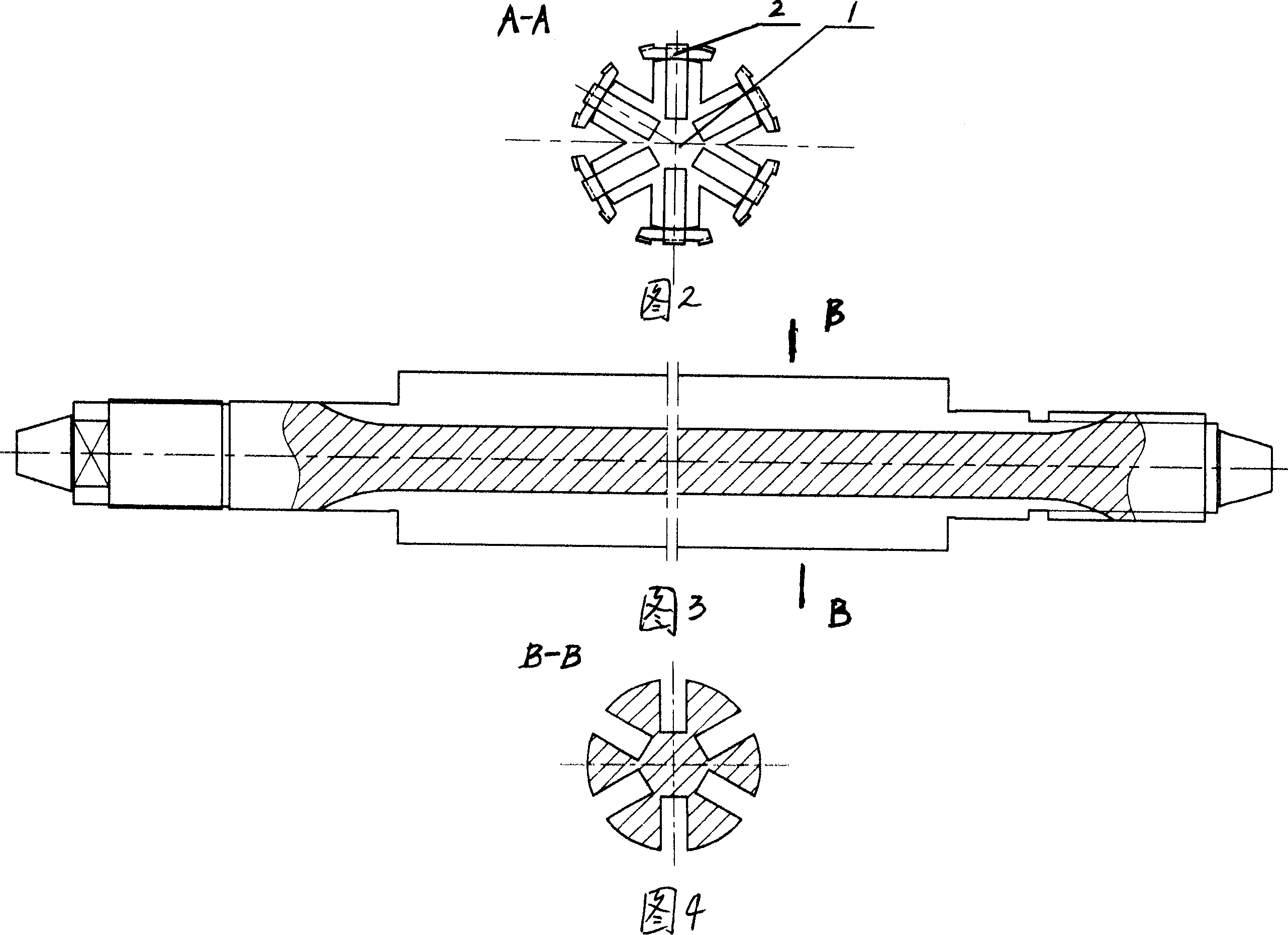

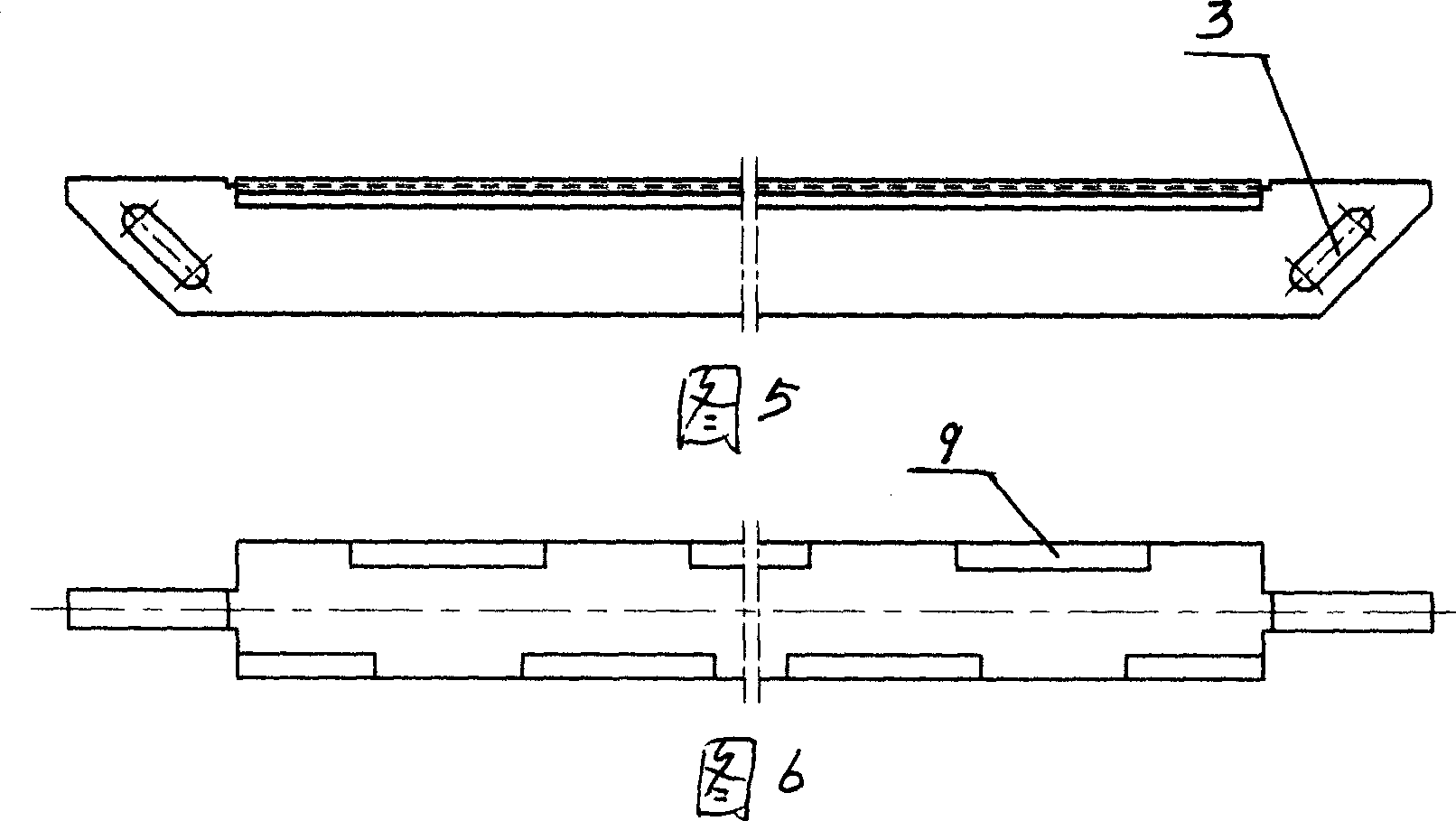

[0015] Referring to Figure 1 and Figure 2, it can be seen that the internal expansion-type taper adjustable clamp of the present invention includes a mandrel 1, and the radial position of the mandrel 1 is equipped with several "T"-shaped (longitudinal cross-section) support plates 2. The two ends of the support plate 2 have oblique (set) long grooves 3 (as shown in Figure 2, Figure 5, and Figure 6); at both ends of the mandrel 1, an umbrella rib is installed at the top of the support plate 4. A pin 5 is provided in the umbrella rib 4, and the pin 5 is sleeved in the oblique long groove 3 of the support plate 2; one end of the mandrel 1 and the outside of the umbrella rib 4 are sequentially equipped with a thrust ring 6 and a nut 7. The other end of the mandrel 1 and the outside of the umbrella rib 4 are sequentially provided with a thrust ring 6 and a nut sleeve 8 . The longitudinal section of the mandrel 1 is composed of a shaft center and several blades (as shown in Figures ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com