Middle-speed high-pressure multi-stage centrifugal blowing machine

A blower, centrifugal technology, applied in the field of multi-stage centrifugal blower, can solve the problems of increased product cost, high noise, high speed and blade load, to improve efficiency and reliability, low manufacturing cost and transportation cost, and structural tight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Although the specific implementation solutions of the present invention will be described below with reference to relevant drawings, it should be understood that the implementation solutions here are only examples and illustrations, and there are many other solutions that can be implemented according to the principle of the present invention. It will be apparent to those skilled in the art that various changes and modifications within the purview of the present invention will be considered to be within the spirit, scope and considerations of the present invention, which will be further defined in the appended claims .

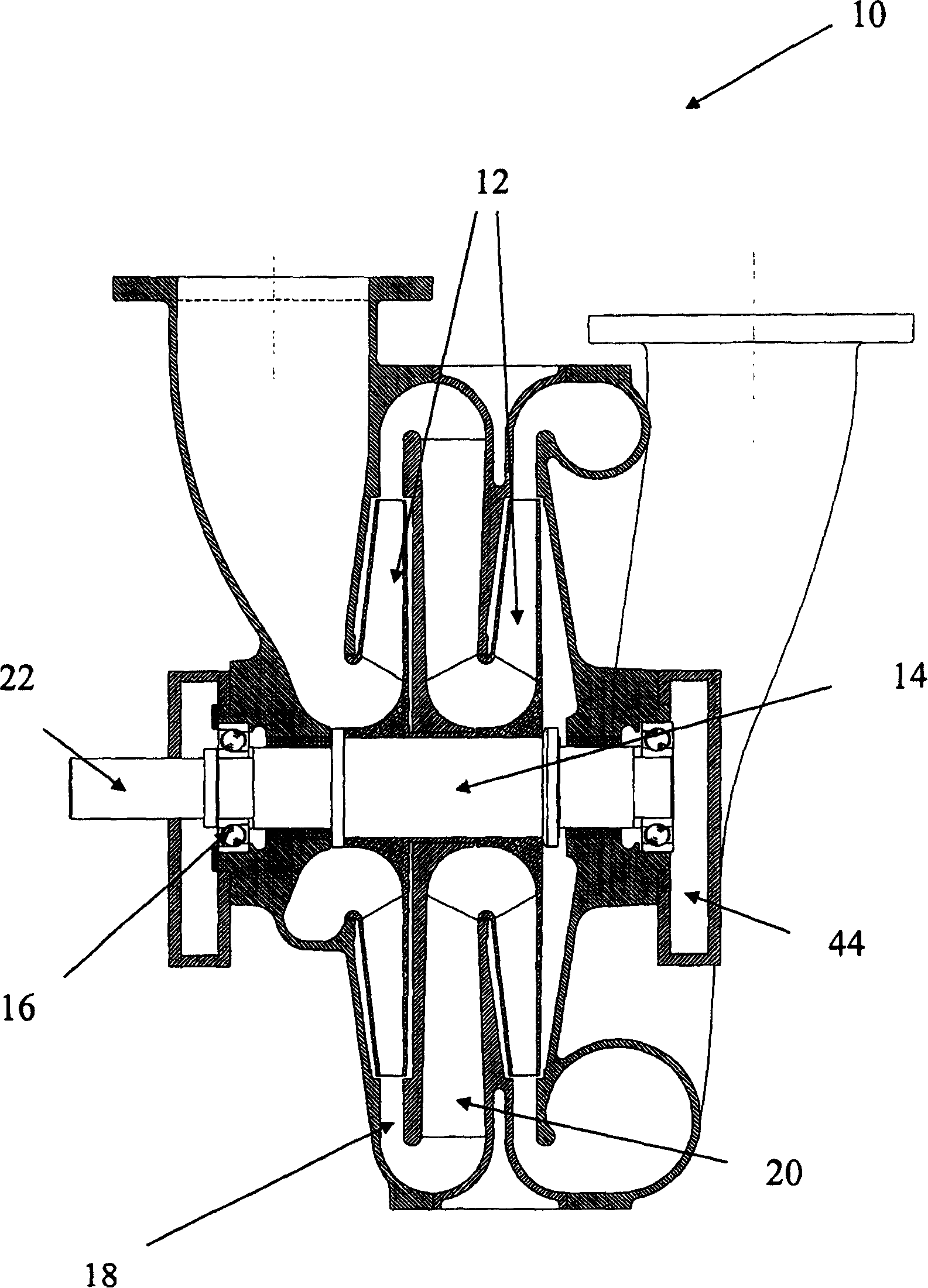

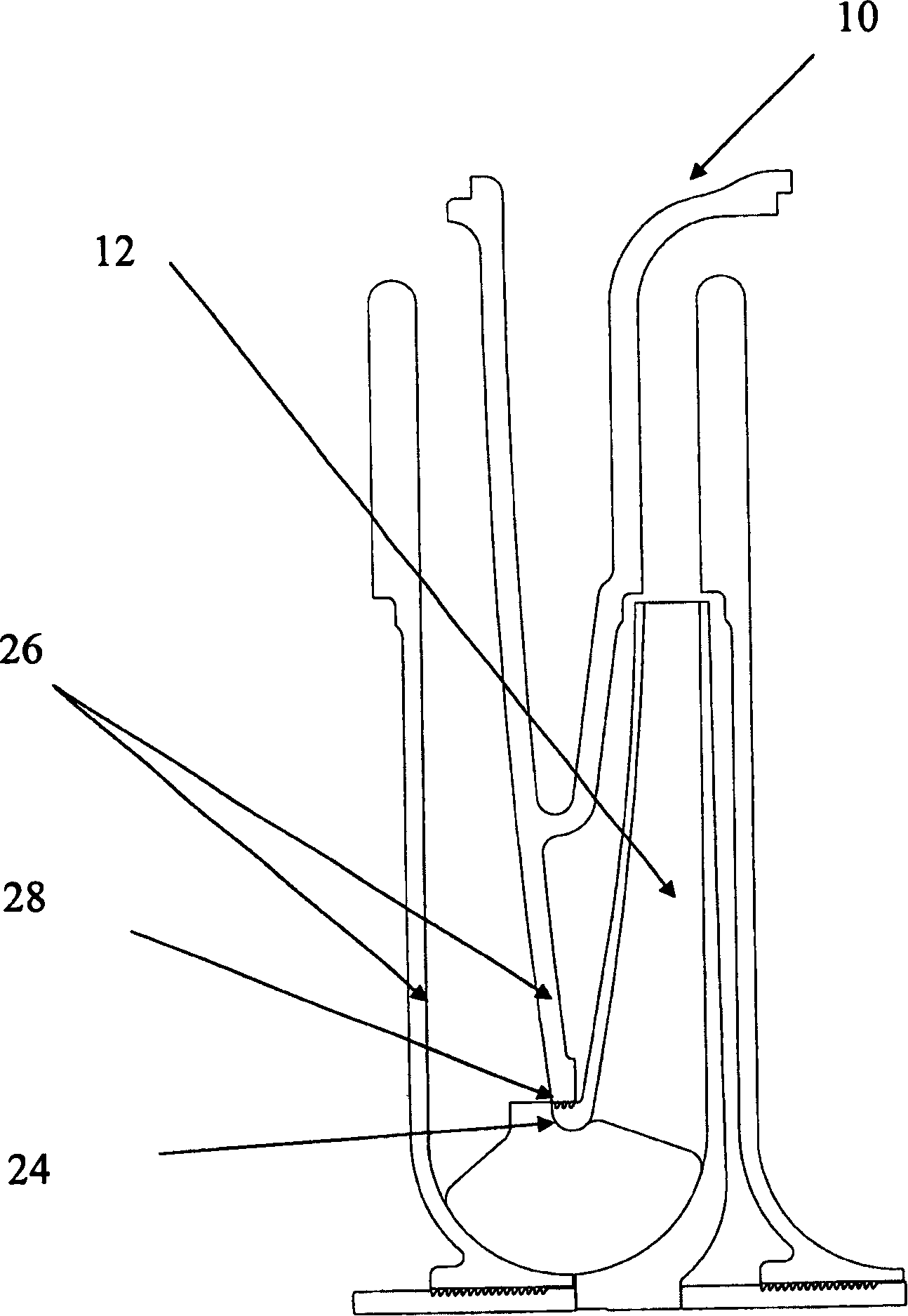

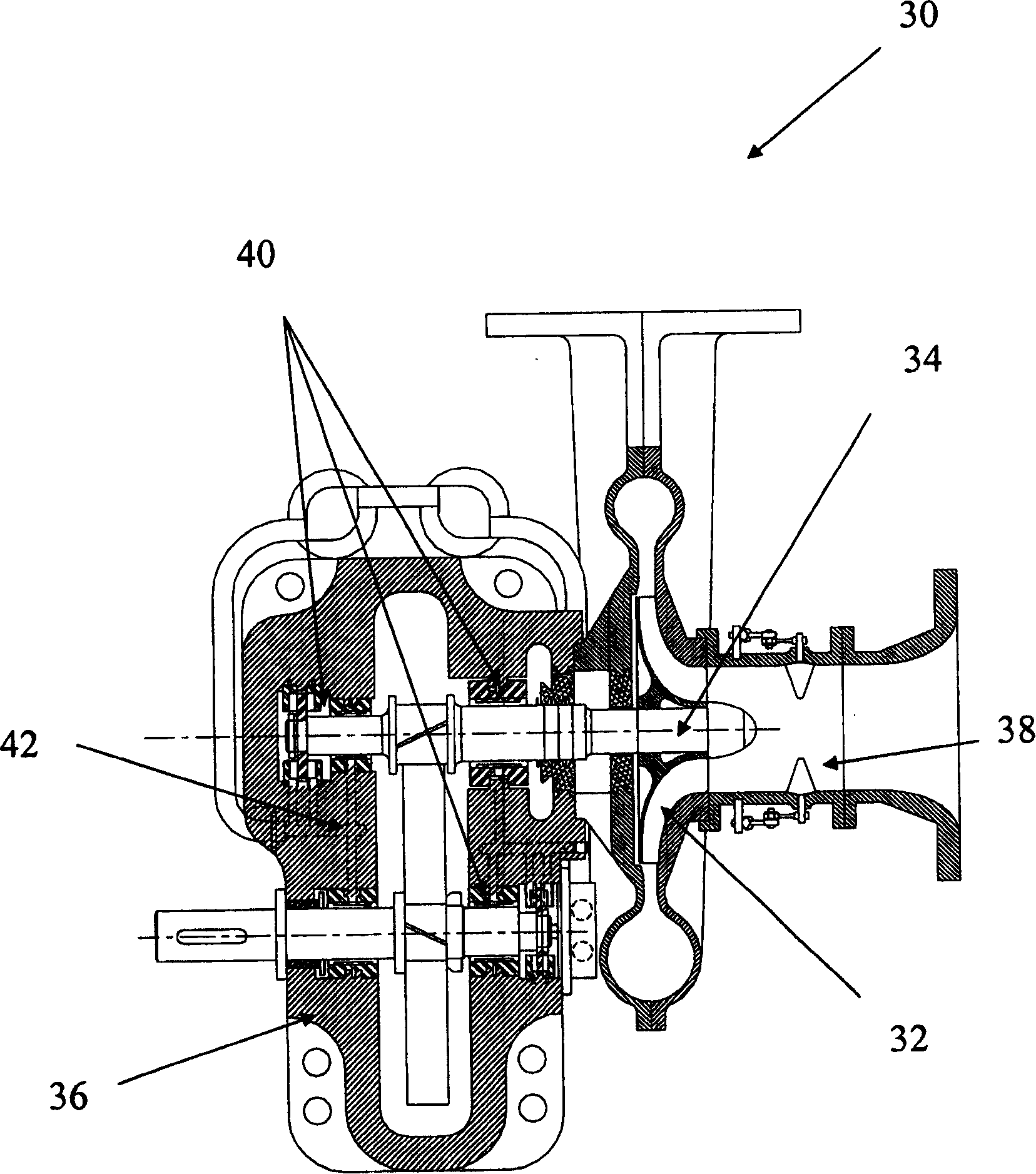

[0051] refer to Figure 4 , in 100 is the best solution to realize the high-pressure conjoined gear-driven multi-stage (IGMS) centrifugal blower of the present invention.

[0052] Such as Figure 4 As shown, the IGMS blower 100 of the present invention has several aluminum (or steel) impellers 112 arranged in series on the same high-speed gear shaft 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com