Matching Method of Variable Rotation Speed of Second Stage Impeller with Two Stage Impellers of Contra-Cyclone Fan

A matching method, cyclone technology, applied in mechanical equipment, non-variable capacity pumps, machines/engines, etc., can solve the overload of the second stage motor, the pressure rise and power rise of the second stage impeller too fast, the second stage Impeller pressure rise and efficiency drop too fast, etc., to reduce the load, expand the blocking condition margin, and expand the efficient working range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of the present invention will be specifically described below in conjunction with the accompanying drawings.

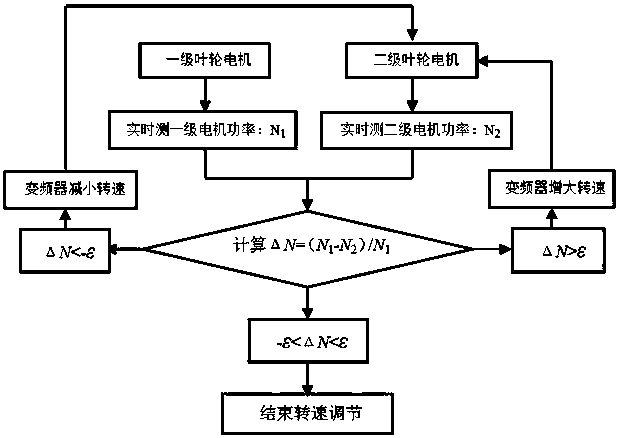

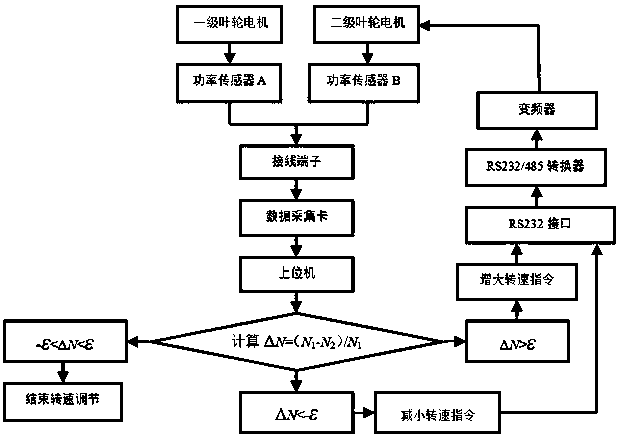

[0020] Such as figure 1 As shown, a method for matching the variable speed of the second-stage impeller with equal power to the two-stage impeller of the counter-cyclone fan according to the present invention includes the following steps,

[0021] S1: Real-time measurement of the input power N1 and N2 of the first-stage impeller motor and the second-stage impeller motor; among them, the input power of the first-stage impeller motor and the second-stage impeller motor is measured by the first power sensor and the second power sensor respectively ;

[0022] S2: Calculate the power difference between the two impellers

[0023] S3: If the power difference △N of the two-stage impellers is within the error limit, that is, when -εε, increase the speed of the second-stage impeller ; If ΔN<-ε, then reduce the speed of the second-stage impelle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com