Puncher

A perforating device and a technology of a rotary drive mechanism, which is applied in metal processing and other directions, can solve the problems of time-consuming and laborious wiring operations, hindering perforation operations, and difficulty in seeing, etc., and achieve the effect of reducing the number of wiring, shortening the time of wiring operations, and improving the efficiency of perforation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Hereinafter, the punching device according to the embodiment of the present invention will be described based on the drawings. The perforating device uses a rotating punch to make holes in the perforated materials such as sheets, sheet bundles, wooden boards, metal foils, and metal plates.

[0049] (Composition description)

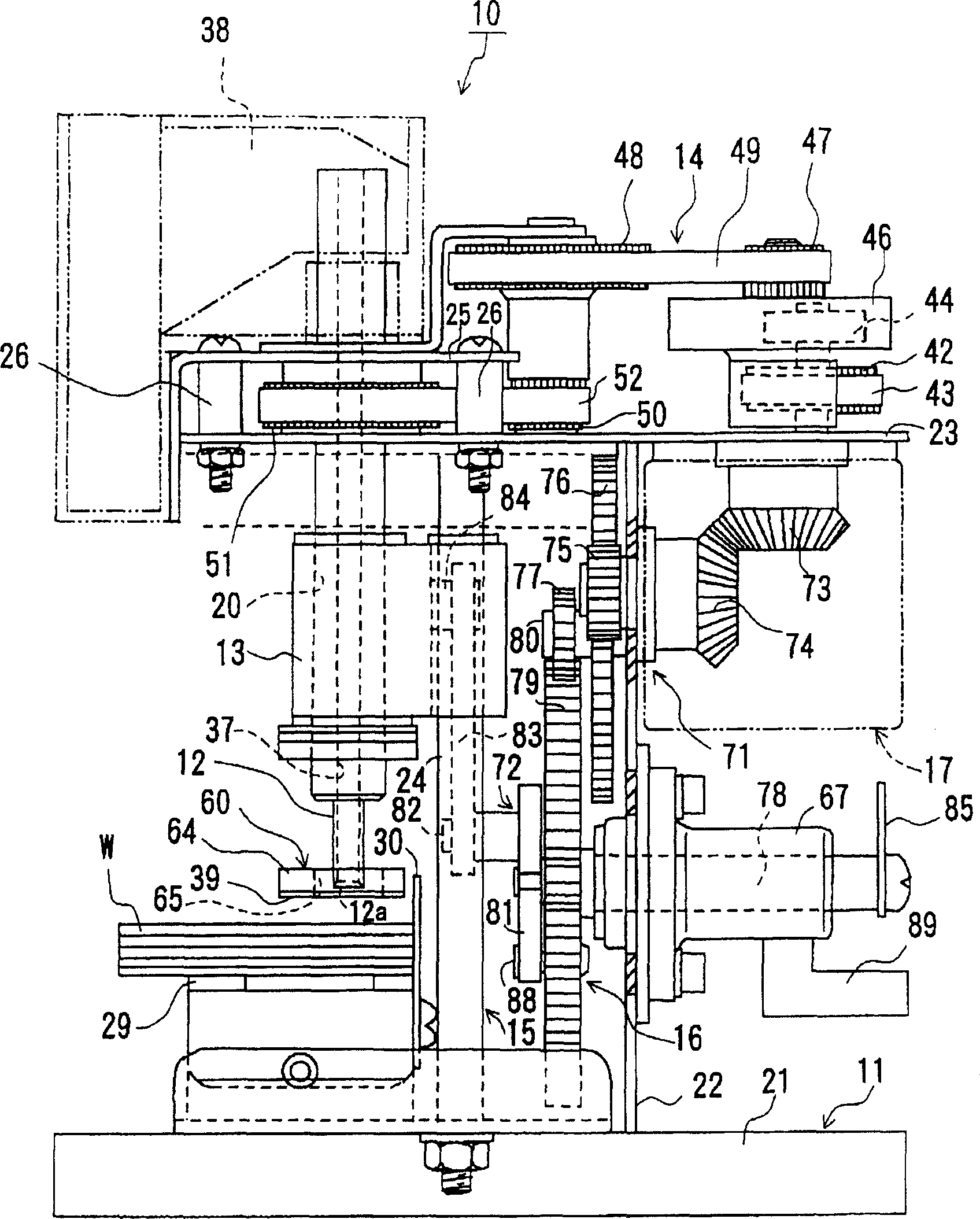

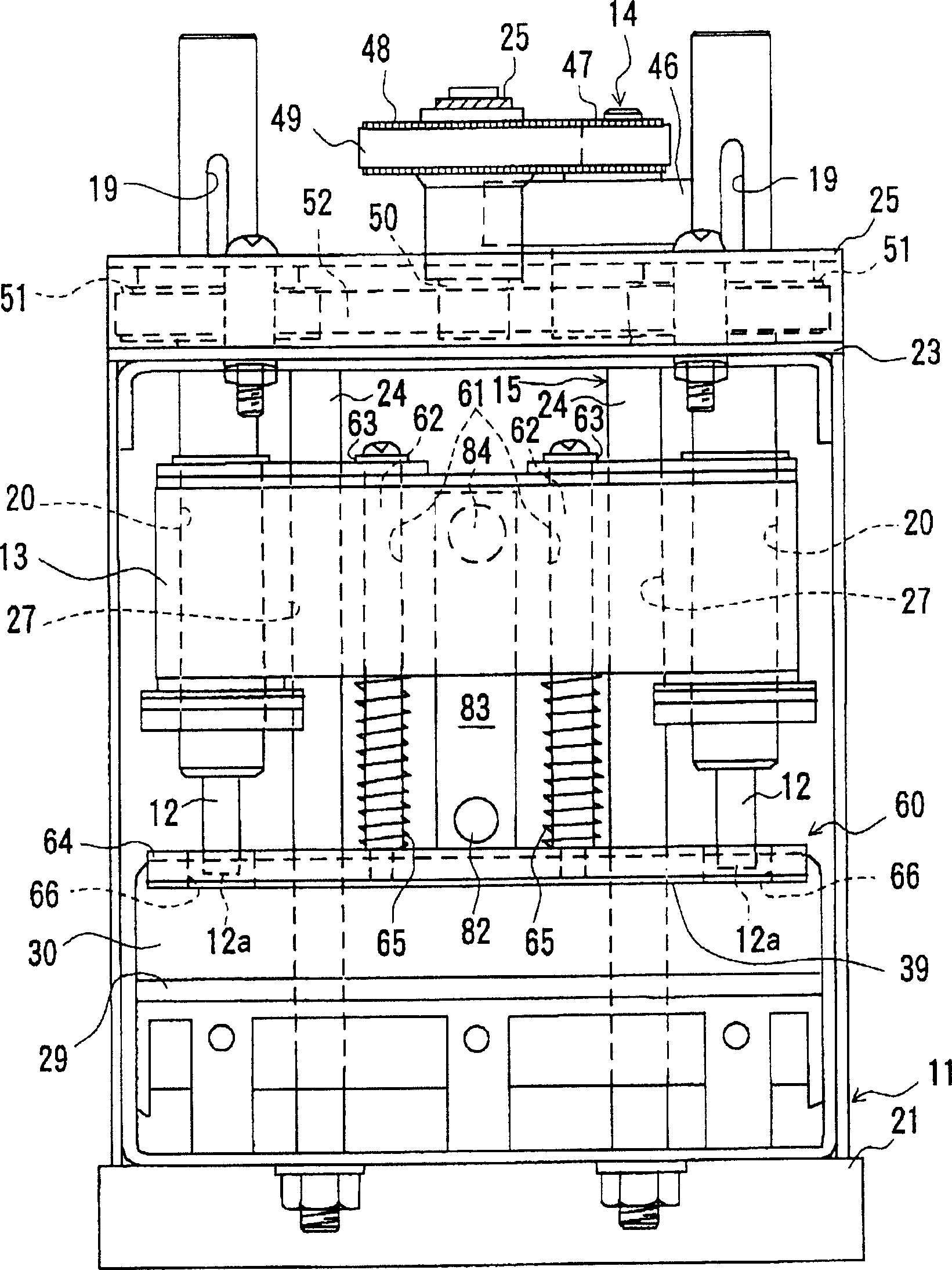

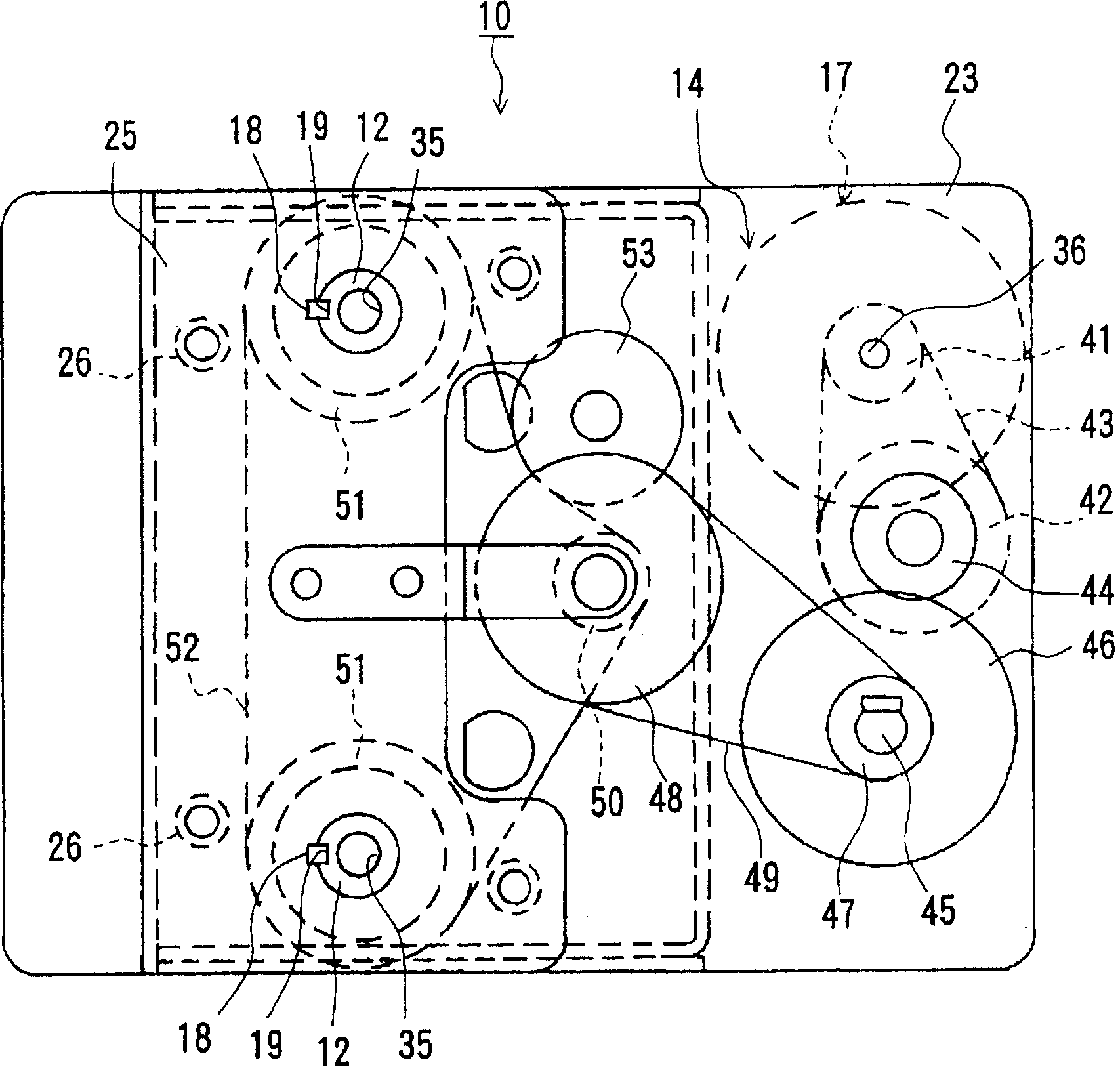

[0050] Such as Figure 1 to Figure 6 The punching device 10 shown has: a device body 11; a punch 12 that makes a hole in the material W to be punched; a lifting body (punch support) 13 that supports the punch 12 to rotate freely and cannot move axially; The rotary drive mechanism 14 for the rotation of the head 12; the reciprocating support mechanism 15 that supports the lifting body 13 freely reciprocating on the device body 11; the reciprocating drive mechanism 16 that makes the lifting body 13 reciprocate; the setting to make the reciprocating drive mechanism 16 move The motor 17 and the like in the main body 11 of the device. The piercing device 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com