Head substrate and thermal head substrate

A head substrate and driver technology, applied in printing and other directions, can solve problems such as the difficulty of miniaturization and cost reduction of thermal heads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

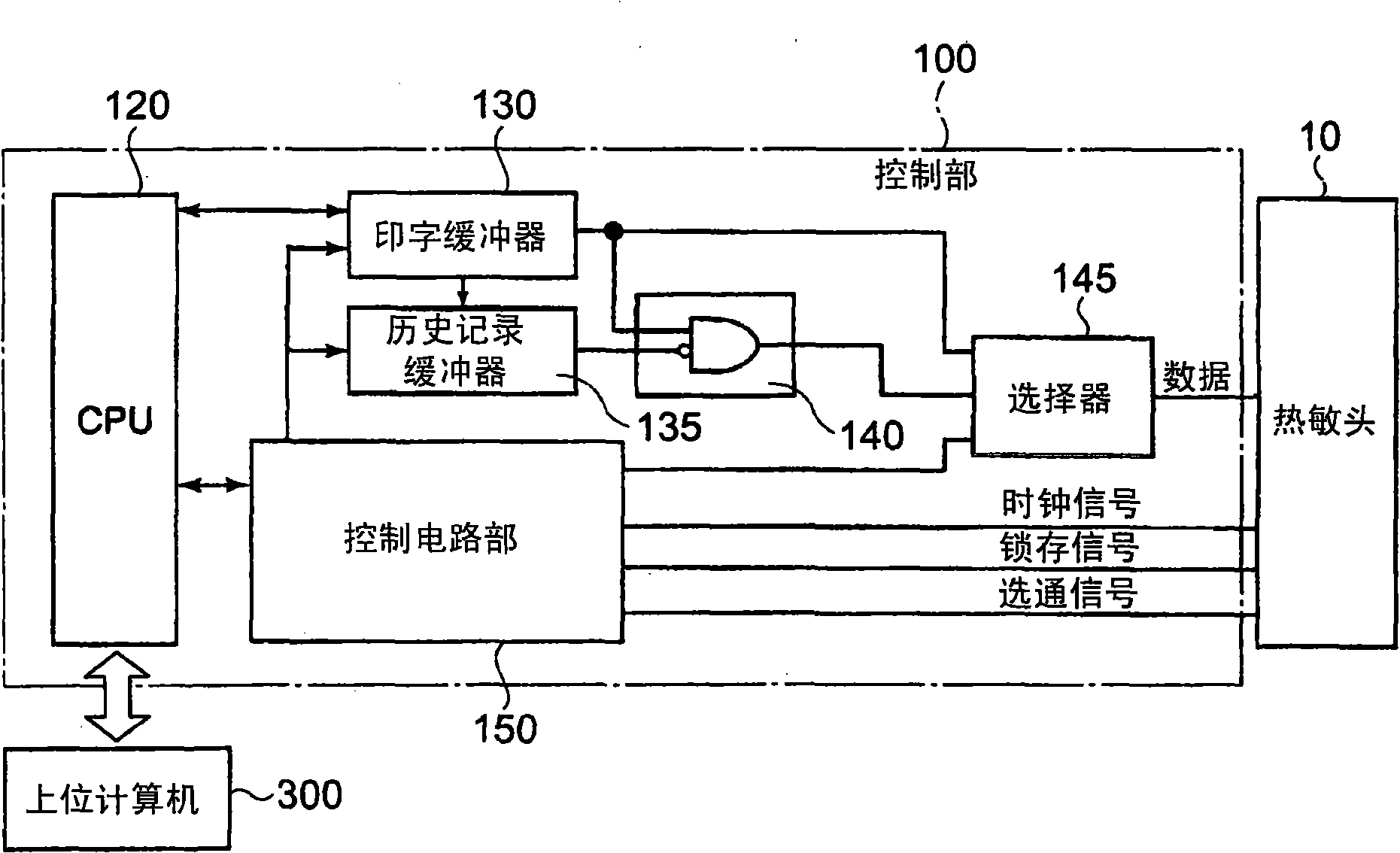

[0045] (about thermal head)

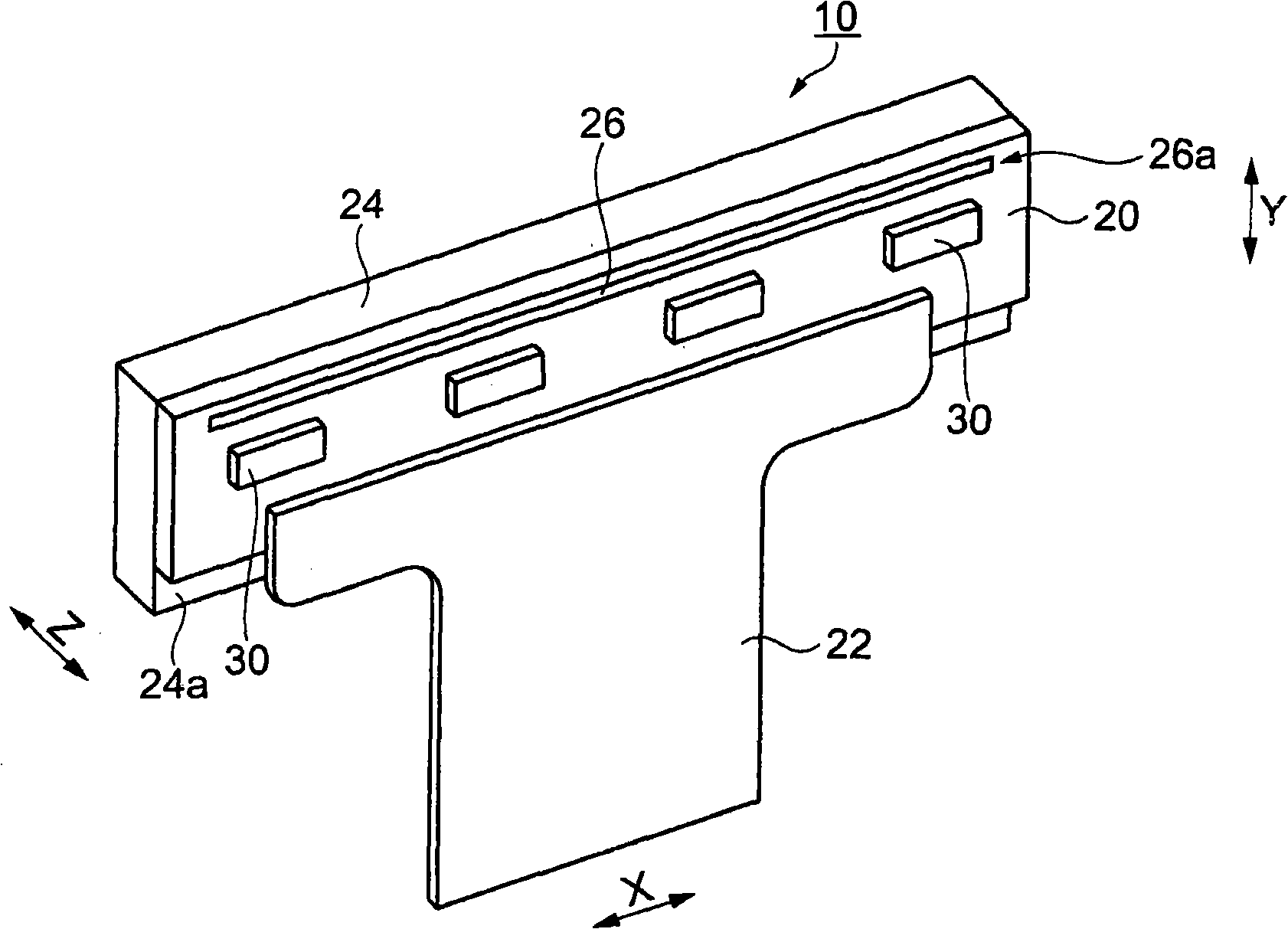

[0046] Regarding the thermal head of the first embodiment, reference will be made to figure 1 illustrate. figure 1 It is a perspective view of the appearance of the thermal head. in, figure 1 The X direction shown indicates the width direction of the thermal paper to be printed when the thermal head is used in a thermal printer, the Y direction indicates the paper conveying direction of the thermal paper in the thermal head, and the Z direction indicates the same direction as the X direction and the Y direction. vertical direction.

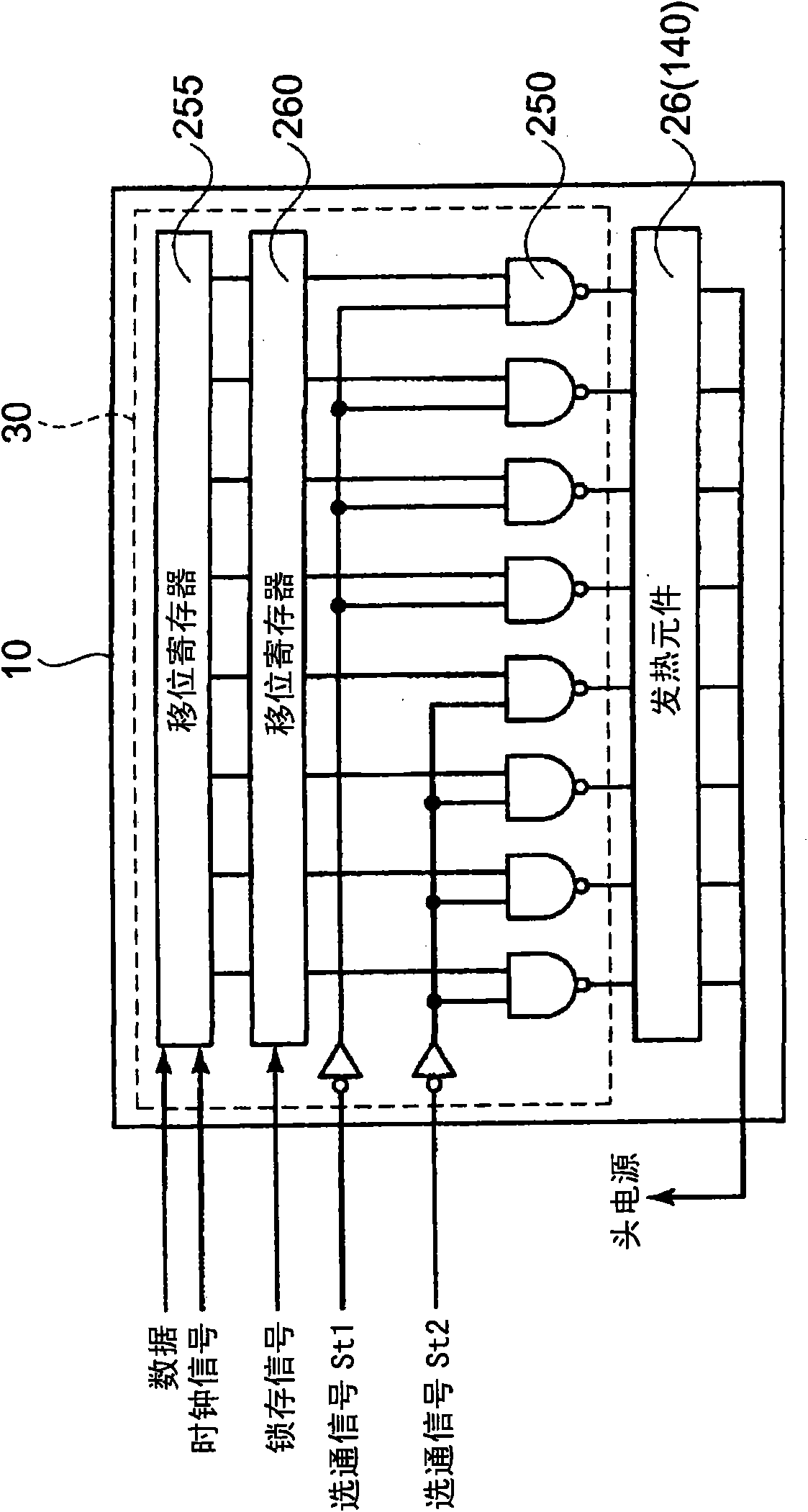

[0047] Such as figure 1 As shown, the thermal head 10 includes: a thermal head substrate 20 , a driver IC 30 , an FPC 22 and a heat sink 24 . The thermal head substrate 20 is made of an insulating material and formed in a long rectangular plate shape, and a heating element row 26a composed of a plurality of heating elements 26 is formed near the end of one long side. The driver IC 30 constitutes a control circui...

no. 2 Embodiment approach

[0097] Here, refer to Figure 7 and Figure 8 The thermal head substrate of the second embodiment will be described. Figure 7 It is a pattern pattern diagram of the thermal head board|substrate of 2nd Embodiment. Figure 8 It is a part of the input-output terminal seen from the input-output terminal side of the driver IC of the second embodiment. In addition, about the same structure and content as 1st Embodiment, the same code|symbol is attached|subjected, and the description is abbreviate|omitted.

[0098] Such as Figure 7 As shown, the thermal head substrate 20A is mounted with a driver IC 30A (refer to Figure 8 ) IC mounting part 31, on the heating element R1 ~ R512 side, from Figure 7 Starting from the right side of the center, it is arranged in a row (the first pad column) in sequence: the first latch pad LAT1, the logic power supply pad VDD, the signal output pad SO, and the output pads that conduct with 128 heating elements 26. The pads DO1 to DO128, the sign...

no. 3 Embodiment approach

[0112] Regarding the thermal head substrate of the third embodiment, refer to Fig. 9 (a), Fig. 9 (b) and Figure 10 to illustrate.

[0113] FIG. 9( a ) shows a pattern layout diagram related to the IC mounting portions 31 c and 31 d , and FIG. 9( b ) shows a pattern layout diagram related to the IC mounting portions 31 a and 31 b. Figure 10 It is a figure which shows a part of the input-output terminal of the driver IC of 3rd Embodiment, Specifically, it is a figure seen from the input-output terminal side. In addition, about the same structure and content as 2nd Embodiment, the same code|symbol is attached|subjected, and the description is abbreviate|omitted.

[0114] As shown in Fig. 9 (a) and Fig. 9 (b), the thermal head substrate 20B is equipped with a driver IC 30B (refer to Figure 10 ) in the IC mounting portion 31, on the side of the heating elements R1 to R512, from the right in FIG. The pad SO, the first latch pad LAT1 , the output pads DO1 to DO128 electrically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com