Striking off device of magnetism stick in thread spinning

A magnetic rod and magnetic technology, applied in textiles and papermaking, etc., can solve the problems of low interruption success rate, low sensitivity, probe tipping, etc., and achieve the effect of reducing material loss, good sensitivity, and good device stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

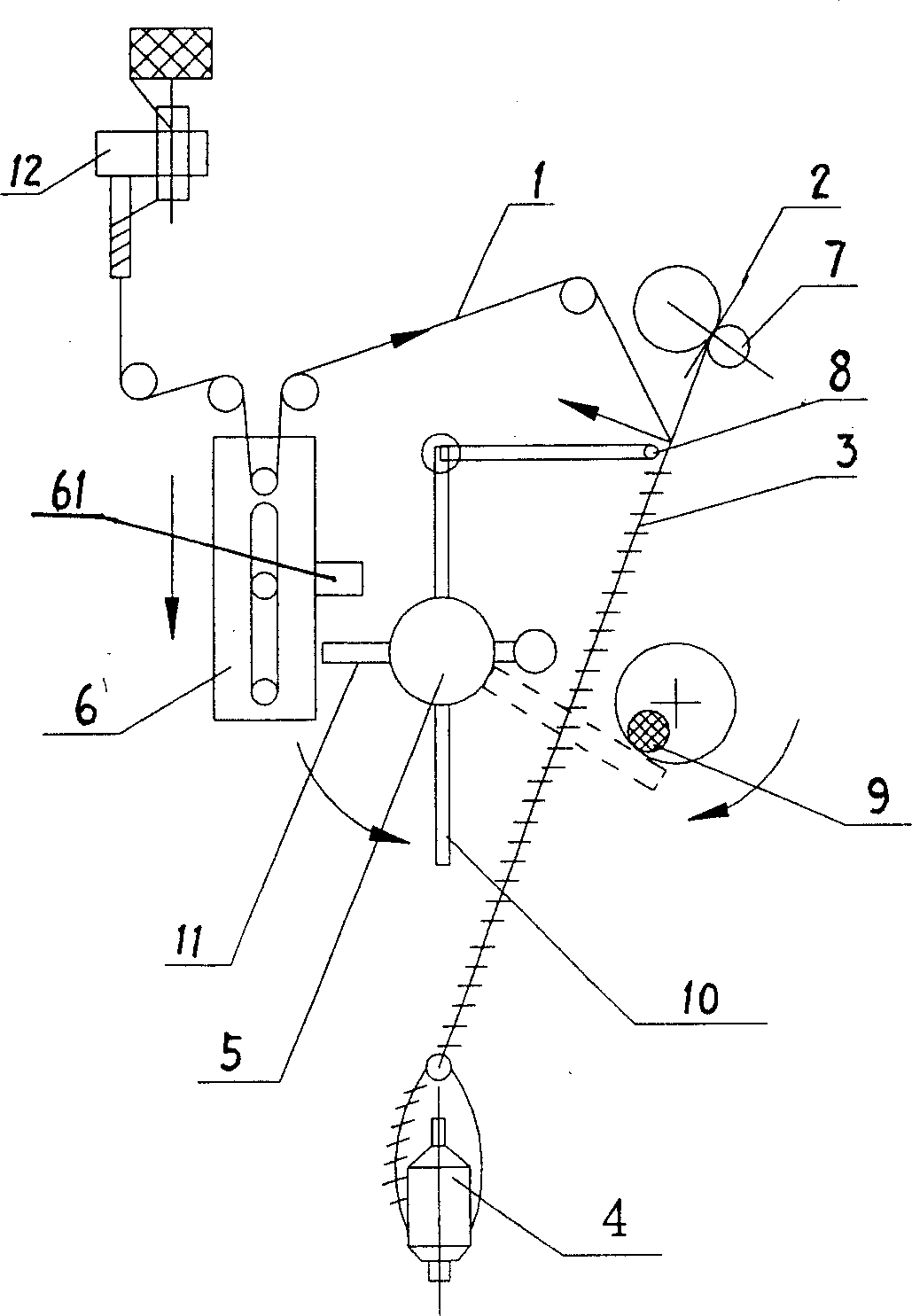

[0034] see Figure 4 As shown in the structural schematic diagram of the magnetic bar breaking device in spinning of the present invention, comprise probe and probe support, probe comprises gravity probe 6 and rotation probe 8, is fixed successively around static balance probe frame 5 support shafts. A dial needle 11, a magnetic breaking plate 10 and a rotating probe 8 are connected.

[0035] The dial needle 11 is fixed on the left side of the static balance probe frame 5, the magnetic breaking plate 10 is fixed on the bottom, and the rotating probe 8 is fixed on the top. The rotating probe 8 is a right-angle bending probe, and a right-angle side serves as a arm, the head of the other section of the right-angled side is located at the parallel twisting place of the long filament 1 and the sliver 2.

[0036] The gravity probe 6 passes through and is suspended by the filament 1 . The gravity probe 6 is provided with a raised edge 61 , and the lower part of the raised edge 61 fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com