Injecting glue type connection method for sealing stainless steel pipe in thin wall

A stainless steel, connection method technology, applied in the direction of non-removable pipe connection, pipe/pipe joint/pipe fitting, passing element, etc., can solve the problem of inconvenient pipe installation and achieve the effect of ensuring reliability

Inactive Publication Date: 2007-02-21

阎金波

View PDF1 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] Although this technical solution solves the connection technical problems of thin-walled stainless steel pipes well through "sealing" and "sticking", special tools are required to process the pipe ends into the required conical shape when installing the pipes. Inconvenience, this is the shortcoming of the program

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

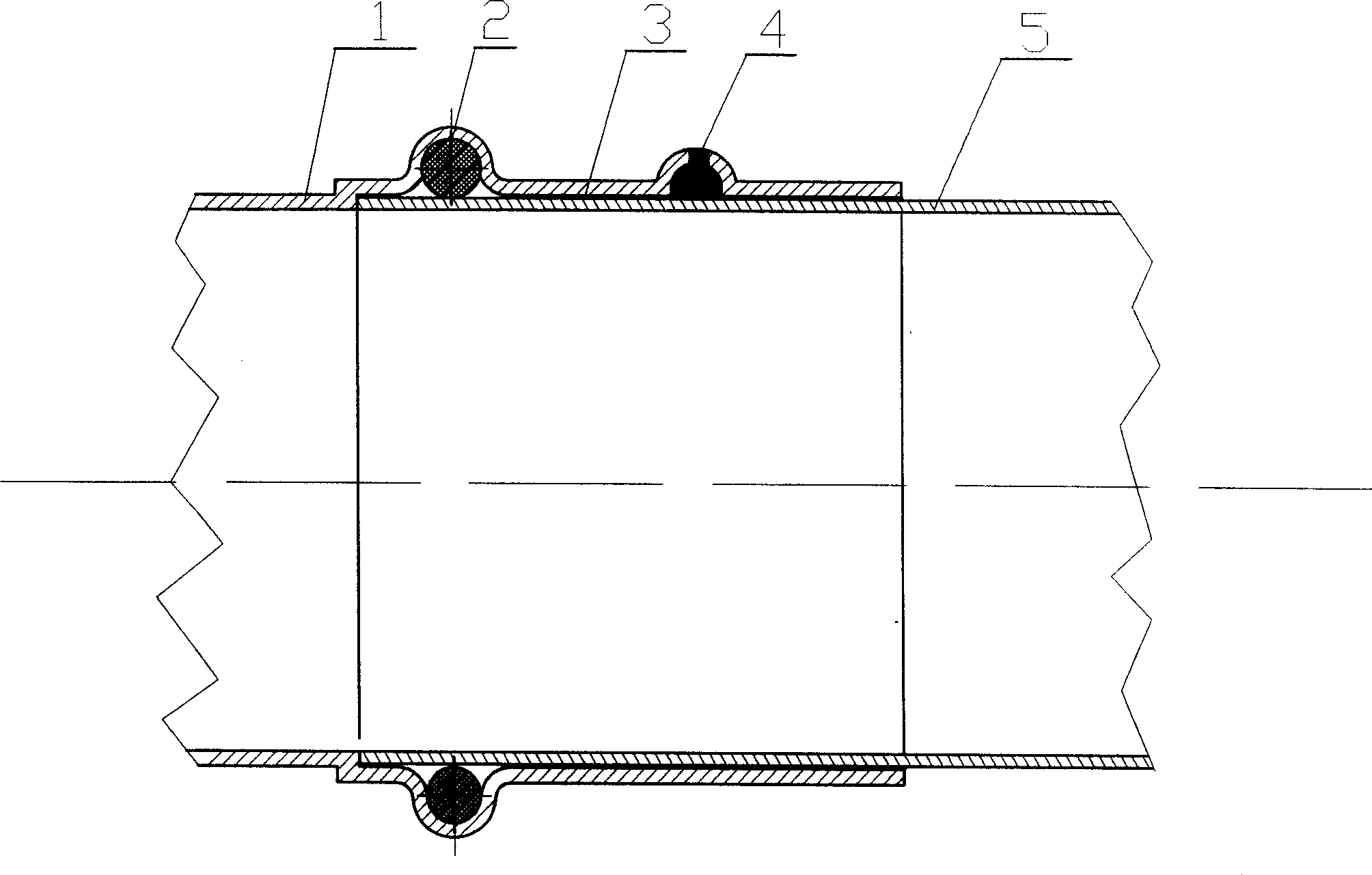

[0017] The pipe fitting body (1) is made of stainless steel with the same material as the pipe (5), and is manufactured by combining pressure processing and argon arc welding. The sealing ring (2) is made of silicon rubber. Adhesive (3) adopts Huitian brand 603 anaerobic adhesive.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

Description

(1) Technical field: [0001] The invention relates to a thin-walled stainless steel pipe sealing and bonding method, which is suitable for thin-walled stainless steel pipes transporting various fluids. (two) background technology: [0002] Disclosed in the publication number CN1587777A is the technical scheme of the thin-walled stainless steel pipe sealing and bonding method. Its pipe fittings are composed of pipe fitting body and sealing ring. The socket of the pipe fitting body is a conical shape with a large outside and a small inside. An annular groove is connected to the smallest inner end of the cone, and a sealing ring is installed in the groove. The end of the pipe is conical with the same conical degree matching the socket of the pipe body. The end of the pipe is inserted into the socket of the pipe fitting body, and the front end of the pipe end passes through the sealing ring until the outer conical surface of the pipe end contacts the inner conical surface of th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F16L13/10

Inventor 阎金波谭承信

Owner 阎金波

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com