Starting speed regulator of liquid resistance in use for squirrel cage motor

A technology of liquid resistance and electric motor, which is applied in the field of liquid resistance start speed control device and electric motor liquid resistance start speed control device, which can solve the problems of insulation and safety, difficulty in speed control technology, application of cage motor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

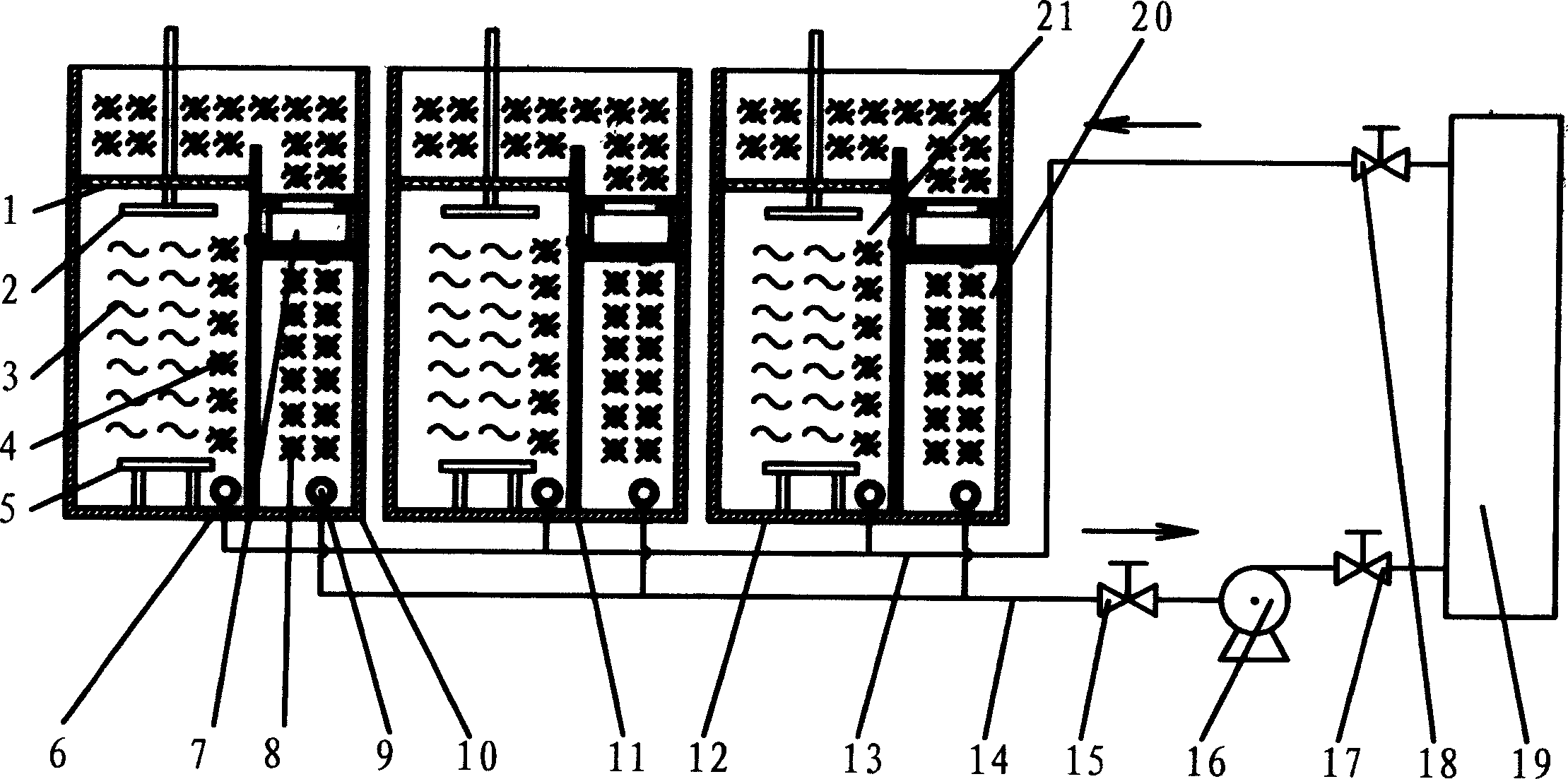

[0010] Such as figure 1 shown. Cabinet body, liquid resistance box 10, 11, 12 box body, moving pole plate 2, static pole plate 5, radiator 19, valve 15, 17, 18, water pump 16, transmission mechanism are all the same as in the existing liquid resistance governor The corresponding is the same. The vertical partition divides the liquid resistance box into a liquid resistance chamber 21 and a slow flow chamber 20. The upper part of the liquid resistance chamber 21 is provided with a filter layer 1 arranged horizontally, and the moving plate 2 and the static plate 5 are arranged in the liquid chamber below the filter layer 1. In the resistance storehouse 21, the electro-hydraulic 3 is housed in the liquid resistance storehouse 21. The lower part of the liquid resistance chamber 21 is provided with a coolant inlet 6 . The upper part of the slow flow chamber 20 is provided with double-layered horizontally arranged closed partitions, and an oil-water separator 7 is installed betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com