High heat-stage non-pinhole polyesterimide enamelled wire insulating paint modifier

An enameled wire insulation, polyester imide technology, applied in the coating and other directions, can solve the problems affecting the service life and safety performance of motors and electrical appliances, the decline of elasticity and soft flexibility, and the decline of the pinhole performance of the paint film, so as to improve the needle-free performance. effect of hole performance, improved continuity, improved pinhole performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

[0011] High thermal grade non-pinhole polyesterimide enameled wire insulation paint modifier, containing 20-30% phenolic resin, 10-20% amino resin, 10-20% acrylic resin, 2-5% silicone surfactant and 30 -60% m-p-cresol mixture. Specific examples are as follows:

[0012] Modifier 1 Modifier 2 Modifier 3 Modifier 4 Modifier 5

[0013] Phenolic resin 20 20 25 25 30

[0014] Amino resin 10 15 15 20 20

[0015] Acrylate copolymer 10 15 15 20 10

[0016] Polyester Modified Silicone 5 3 3 2 2

[0017] m-p-cresol 55 47 43 33 38

[0018] The components are mixed, the temperature is raised to 40-60°C, and the mixture is uniformly stirred to prepare a compound mixture.

[0019] Wherein, the phenolic resin used is an etherified phenolic resin, the amino resin used is a polycyanamide-based amino resin, and the acrylic resin used is a solvent-based acrylic resin.

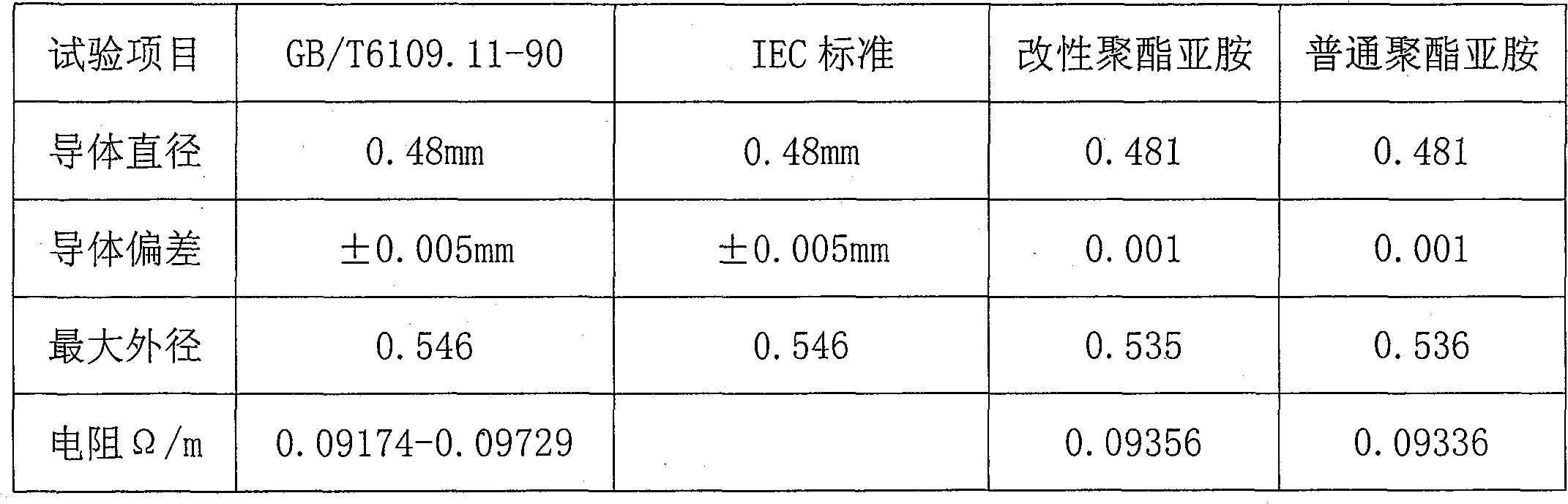

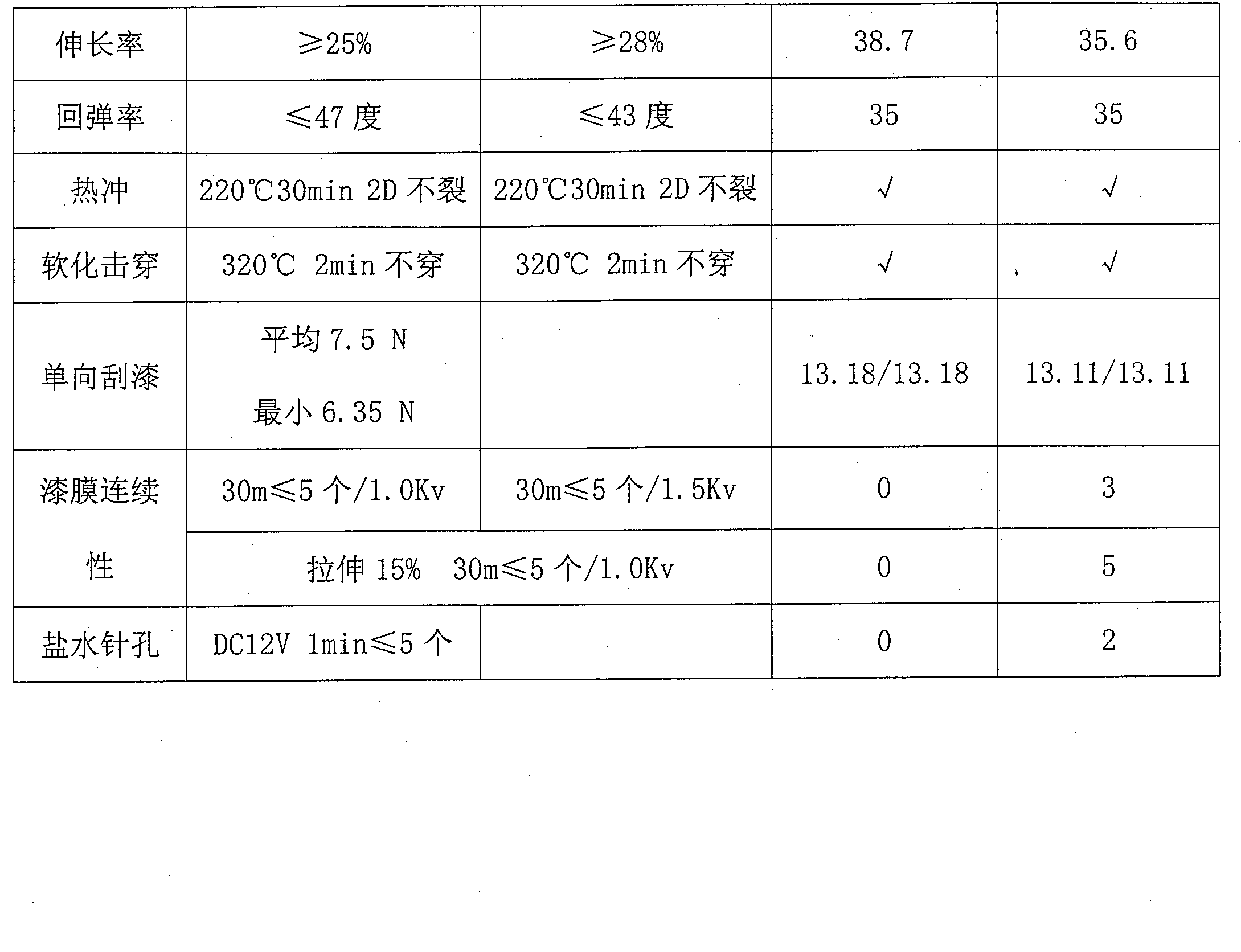

[0020] The enameled wire coated with the polyesterimide enameled wire enamel prepared by the invention ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com