Medium part rolling method of looping part of paper machine

A technology of coiling section and paper machine, applied in the wet section of paper machine, paper machine, paper making, etc., can solve the problems of inconsistent tension, dead lines, large amount of lost paper, etc., to eliminate dead lines and reduce bottoming. Dead lines, the effect of improving paper quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing.

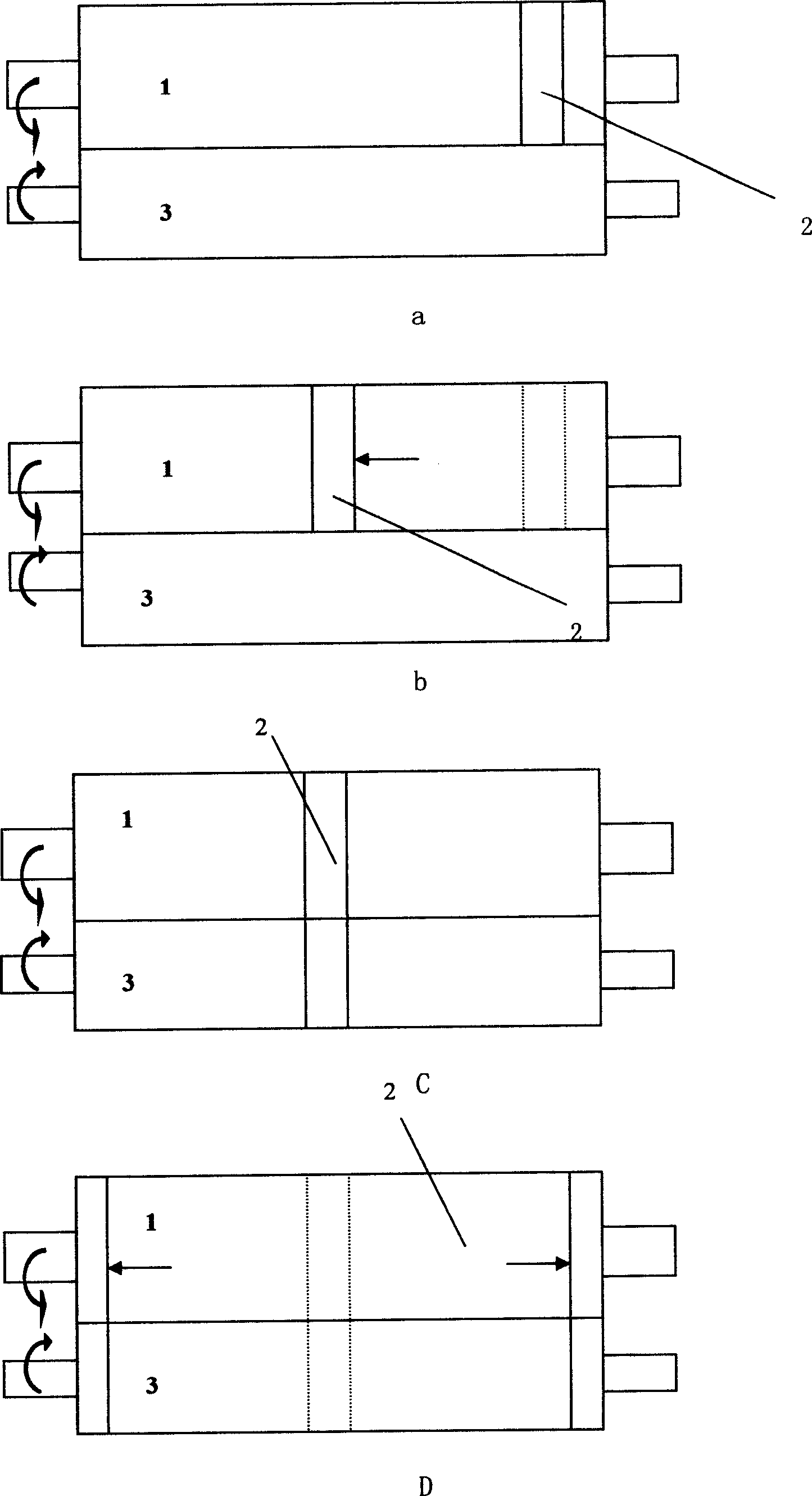

[0014] The present invention adopts the method that the paper strip is rolled up from the middle part in the take-up part of the paper machine, and then fully widened. In the accompanying drawings, 1 is a winding roll, 2 is a paper ear, and 3 is a hollow roll. One side of the winding roll 1 is the transmission side, and the other side is the paper ear operation side. When the paper machine is wound, the paper is smoothly wound by the mutual rotation of the winding roll 1 and the hollow roll 3.

[0015] When winding the threading paper, firstly thread the paper ear 2 on the paper ear operation side of the paper roll 1, see Figure a; after the paper ear 2 is successfully drawn, lead it to the middle position of the paper roll 1, The entire roll web is the paper web after coiling, see attached drawing b; roll up after the paper ear stays in the middle position, see attached ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com