Transmission

A technology of speed changer and speed changer ring, applied in friction transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of inability to obtain speed change and the difficulty of the speed changer ring sliding smoothly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

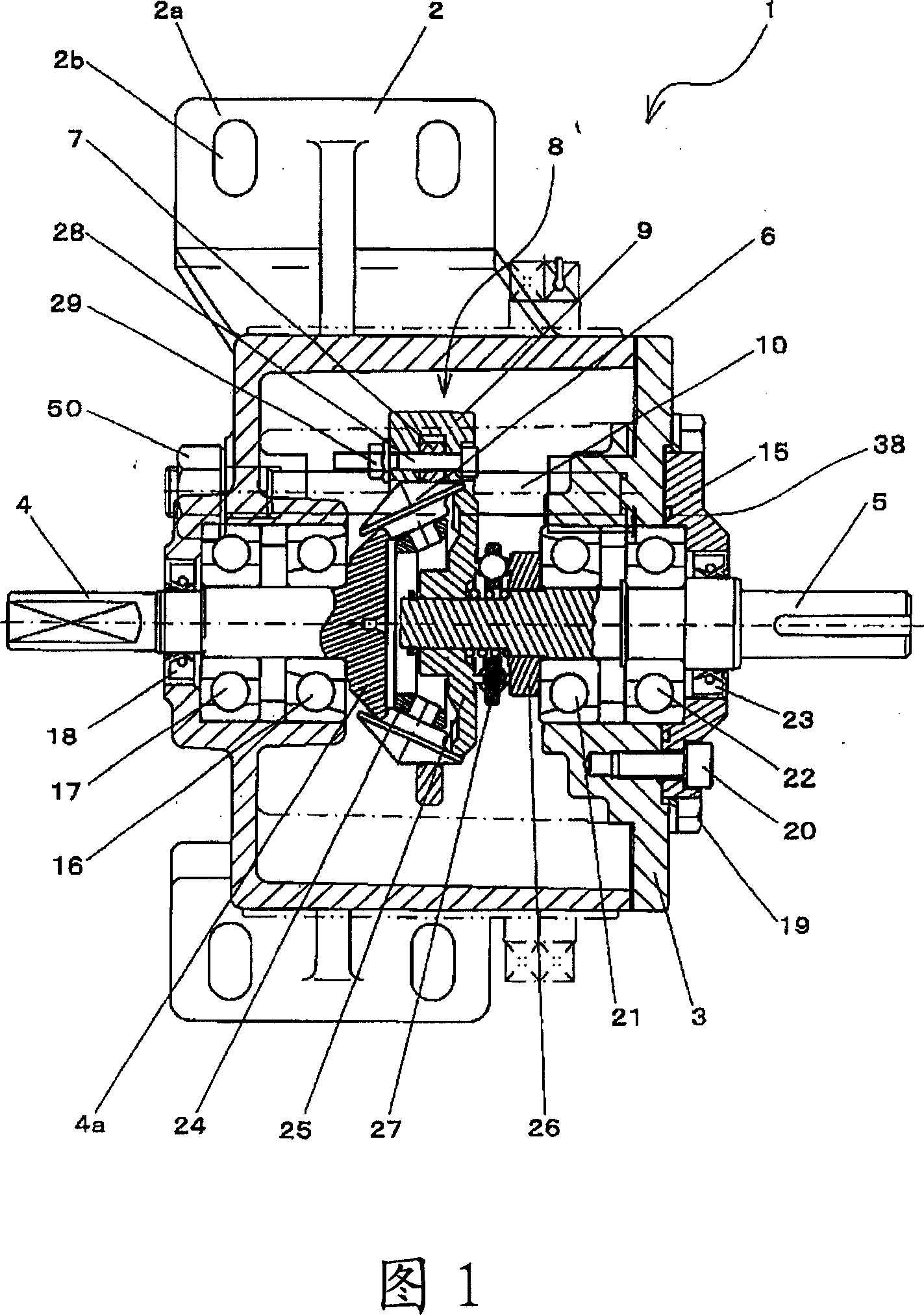

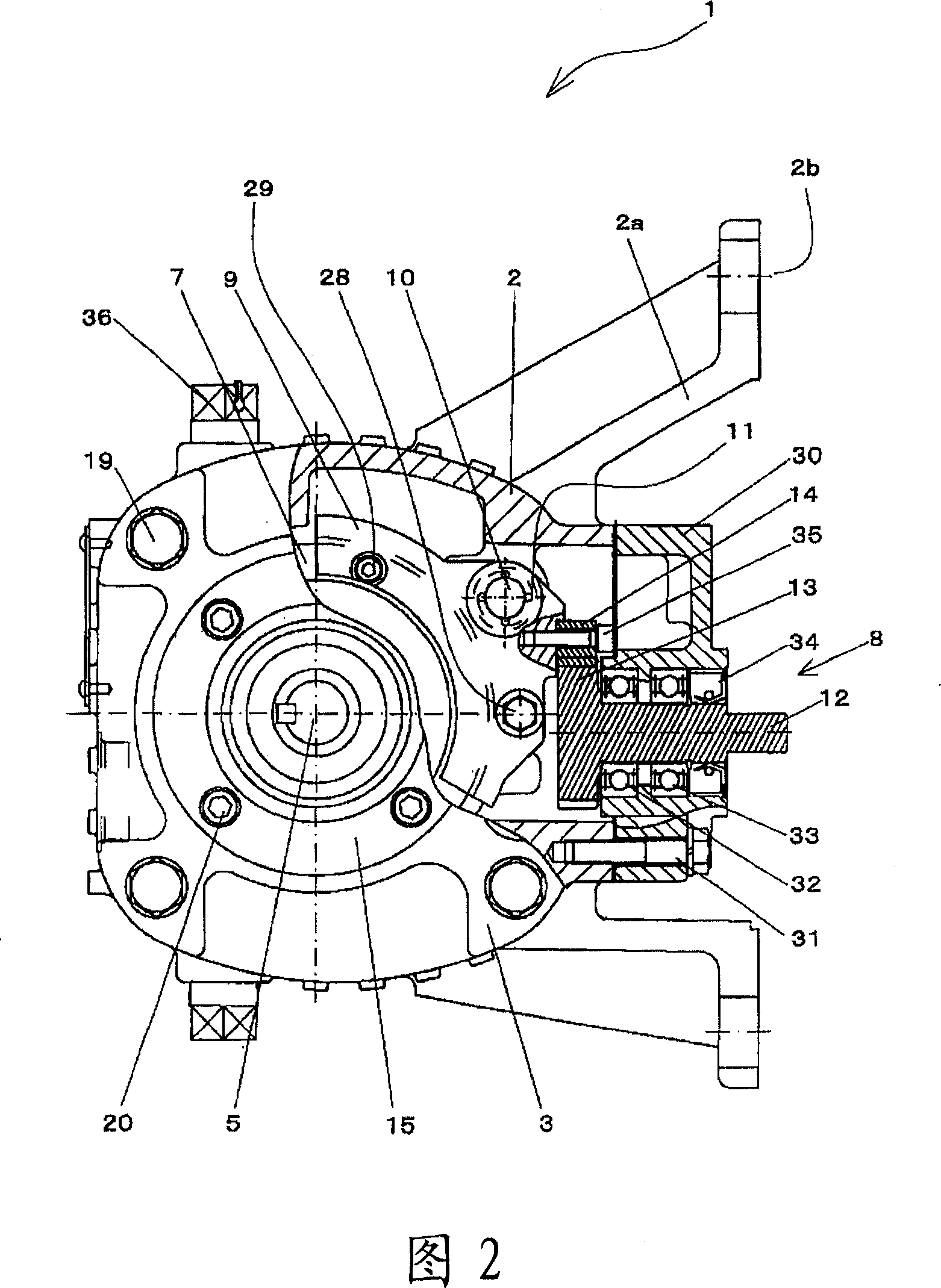

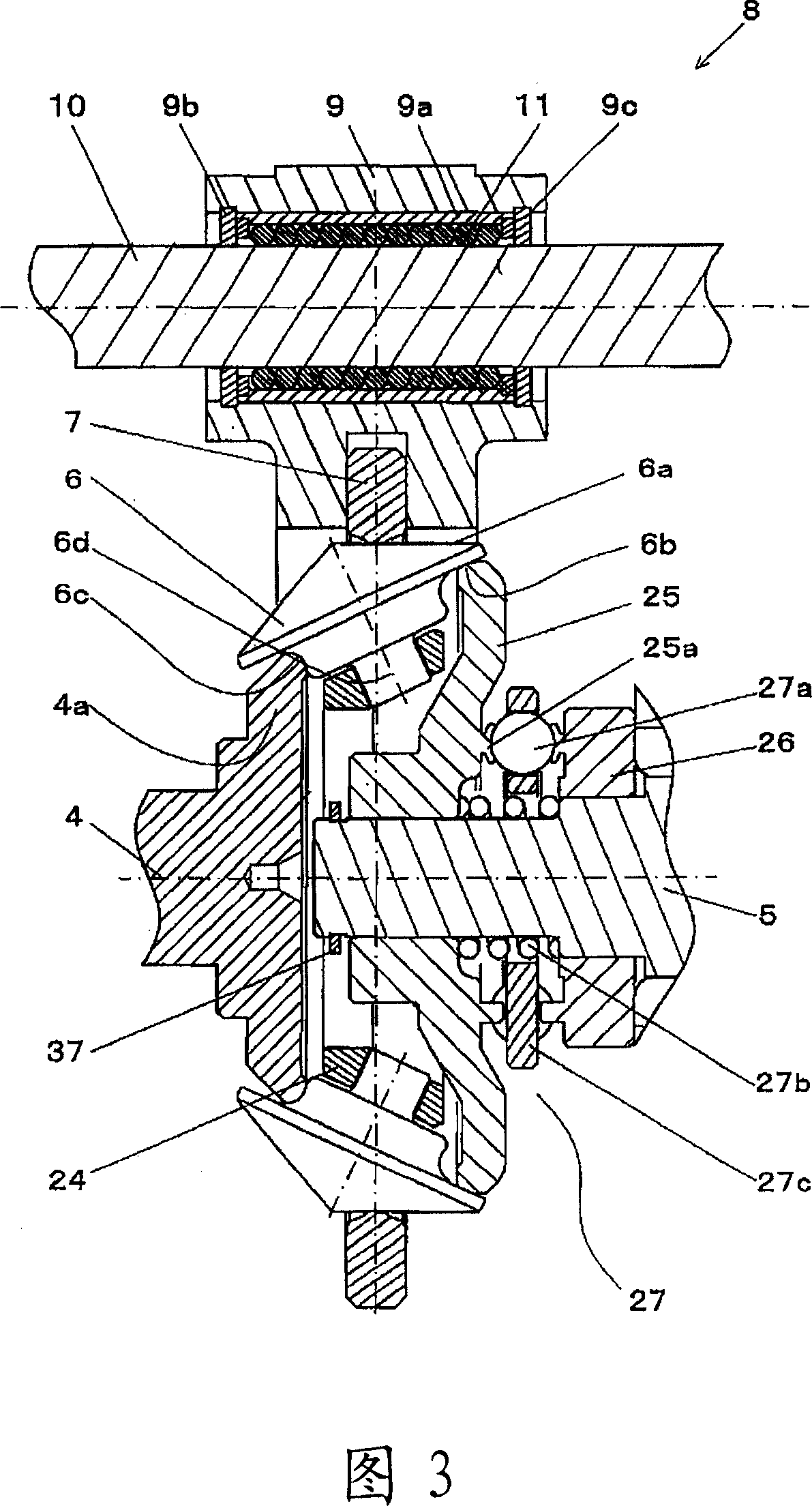

[0023] Next, an embodiment of the transmission of the present invention will be described with reference to the drawings. Fig. 1 is a sectional view showing the overall structure of the speed changer that has used the present embodiment; Fig. 2 is a partial sectional view of the speed changer of the above-mentioned embodiment seen from the arrow A direction in Fig. 1; Fig. 3 is a sectional view showing the above-mentioned embodiment A cross-sectional view of a sliding mechanism of a retainer in a transmission; FIG. 4 is an explanatory diagram illustrating a shifting operation in the transmission of the above-mentioned embodiment.

[0024] As shown in FIG. 1, the transmission 1 has in the housing 2: an input shaft 4 that is rotated by a driving force of a driving motor (that is, a so-called driving source) not shown in the figure; The output shaft 5 on the same axis; a plurality of conical rotors 6 are arranged at intervals on the outer circumference of the input shaft 4 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com