Thermal print head

A technology of thermal printing head and heating resistor, which is applied in printing and other directions, and can solve problems such as deviation of the resistance value of the heating resistor part 91

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Hereinafter, preferred embodiments of the present invention will be specifically described with reference to the drawings.

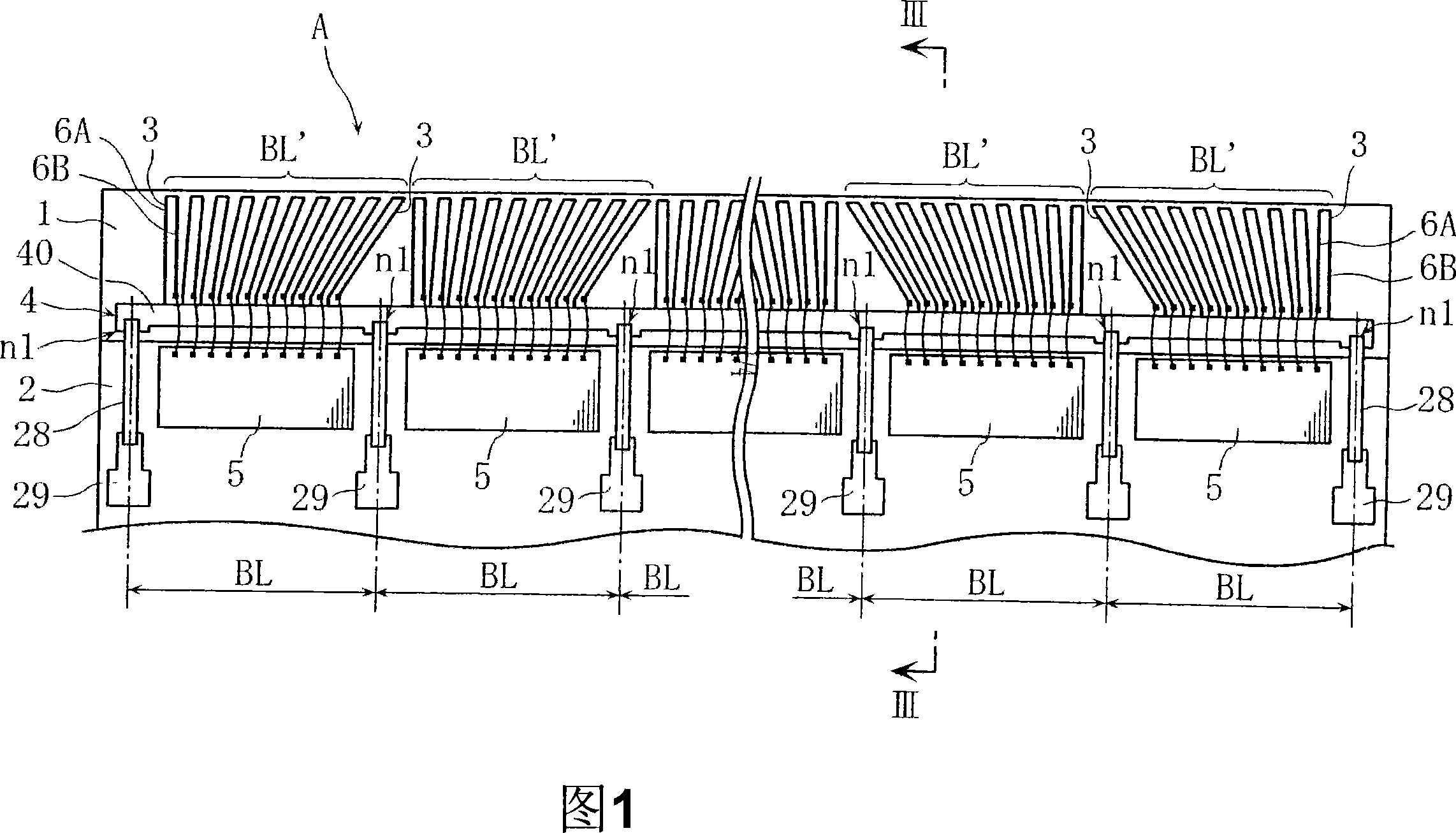

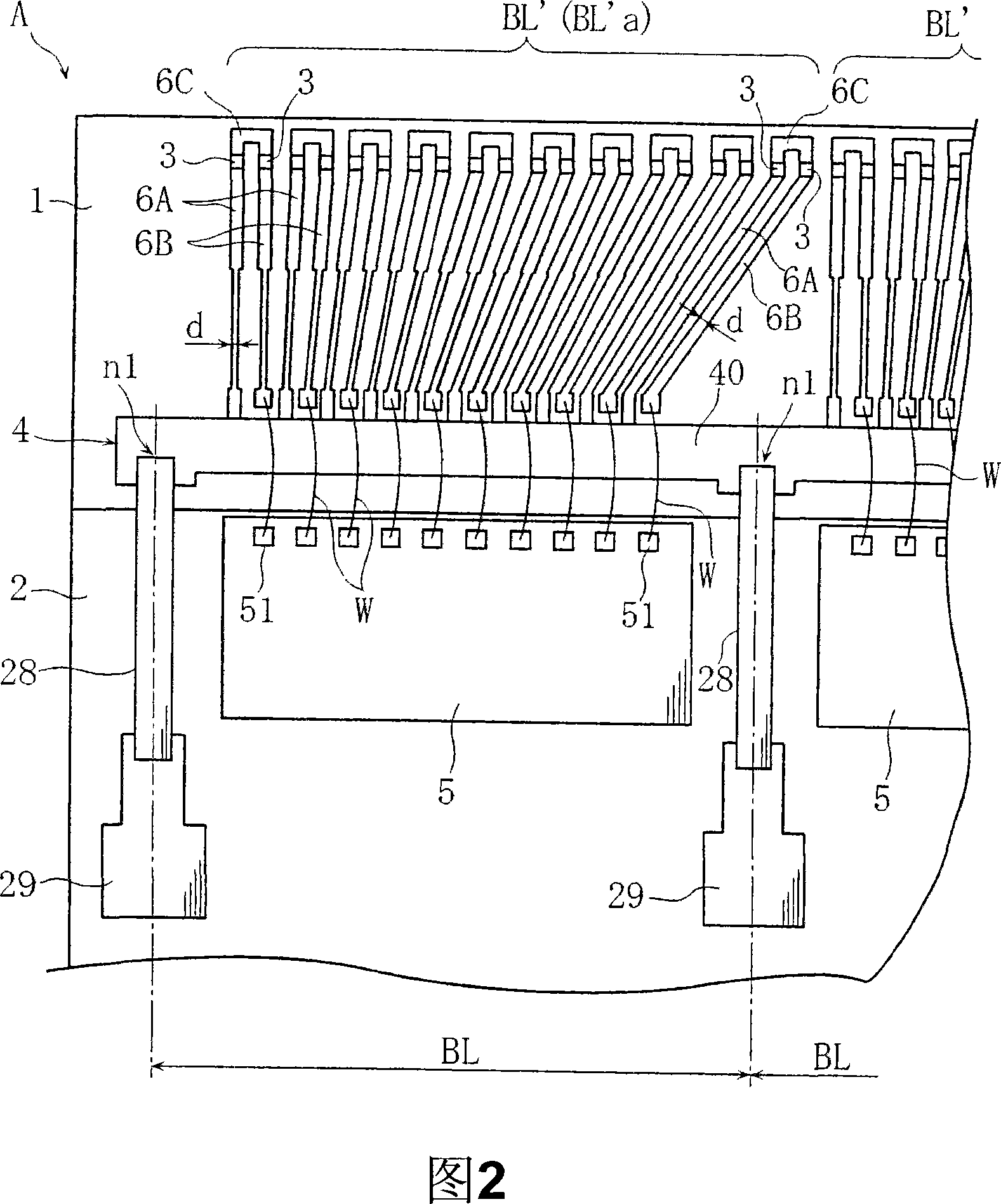

[0023] Figures 1 to 4 show an embodiment of the thermal printing head of the present invention. As shown in Figures 1 and 2, the thermal printing head A of this embodiment includes: a head substrate 1, a printing substrate 2, and a plurality of heating resistors. 3. The common wiring part 4 , the first to third lead wiring parts 6A to 6C, and the plurality of driver ICs 5 .

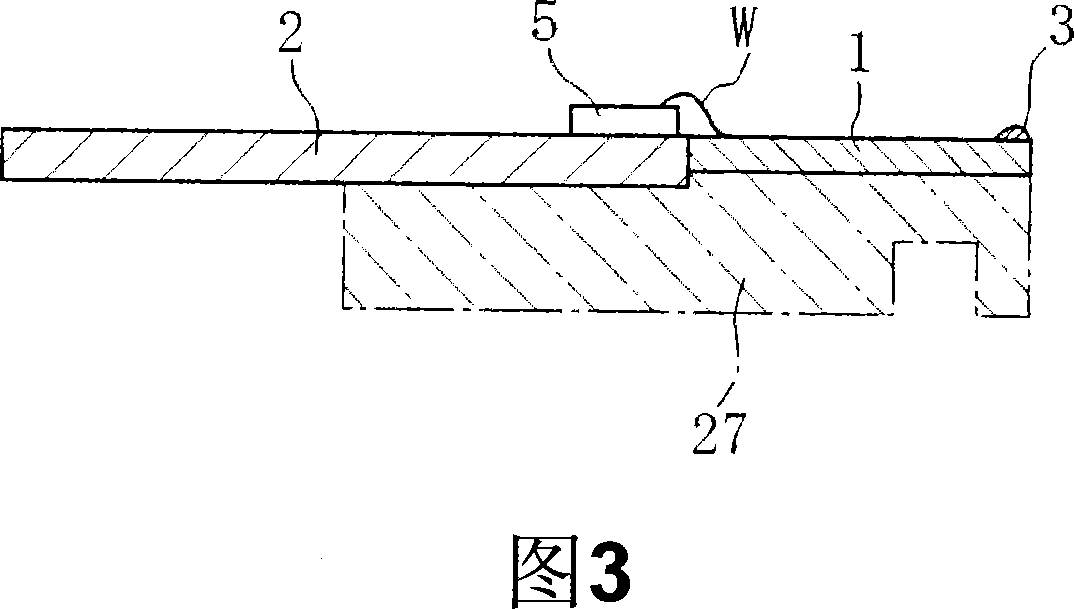

[0024] Both the head substrate 1 and the print substrate 2 are insulative flat plates that are long and rectangular in plan view. The head substrate 1 is made of alumina ceramics, for example. The print substrate 2 is made of, for example, glass epoxy resin. As shown in FIG. 3 , the head substrate 1 and the print substrate 2 are supported by a metal support member 27 and are aligned in the short direction (corresponding to the sub-scanning direction).

[0025] As shown in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com