Electrowinning purification system and purification method for copper electrolytic waste liquid

A purification system and copper electrolysis technology, applied in the field of copper smelting, can solve the problems of slowing down the precipitation rate of copper ions, reducing the initial copper concentration, etc., so as to avoid the generation of massive black copper, reduce the deviation of local copper concentration, and increase the concentration of copper. The effect of large total liquid feed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

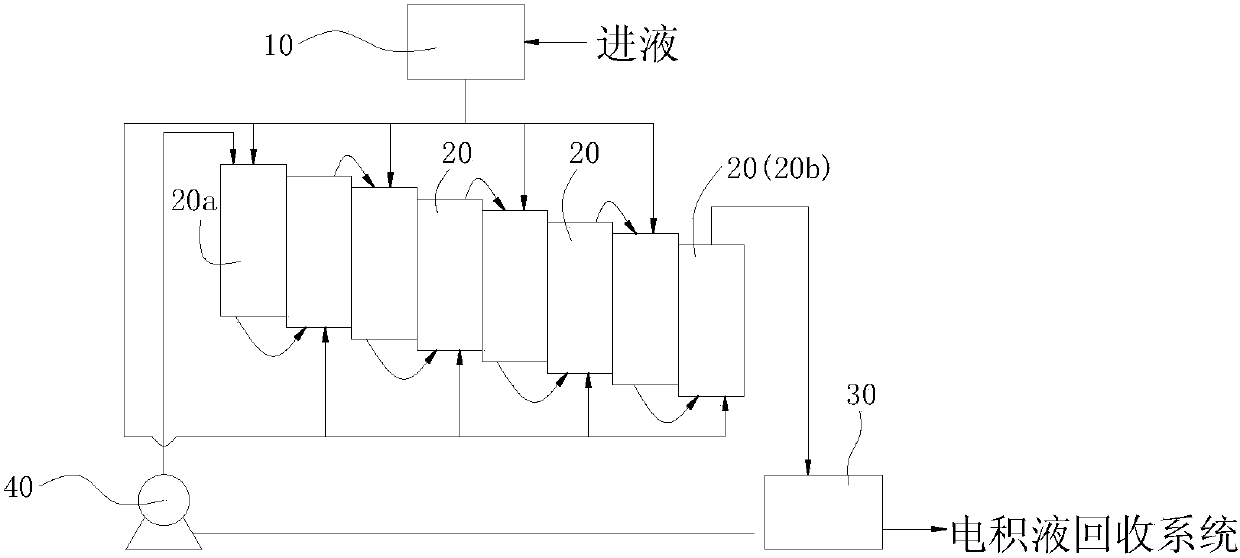

[0011] A kind of electrowinning purification system of copper electrolytic waste liquid, such as image 3 As shown, it includes N electrowinning tanks 20 arranged in sequence, and the copper electrolytic waste liquid after crystallization and precipitation of copper sulfate is connected to each electrowinning tank 20 through pipelines, the first, second, ..., i, ..., The feed liquid outlets of N-1 electrowinning tanks 20 lead to the 2nd, 3rd, ..., i+1, ..., N electrowinning tanks 20 respectively, and the feed liquid outlets of the Nth electrowinning tank 20b lead to The first electrowinning tank 20a and the electrowinning liquid recovery system, wherein i is a natural number between 2 and N-1, and N≥6. According to the experimental summary, it is generally shown that six or more electrowinning tanks 20 are usually arranged to ensure that the decontamination of the copper electrolyte obtained by electrowinning can meet the requirements of subsequent reuse, and the black copper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com