Crane lower body optimised for transport

A crane and chassis technology, applied in the field of crane chassis, can solve the problems of high crane operation and use costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

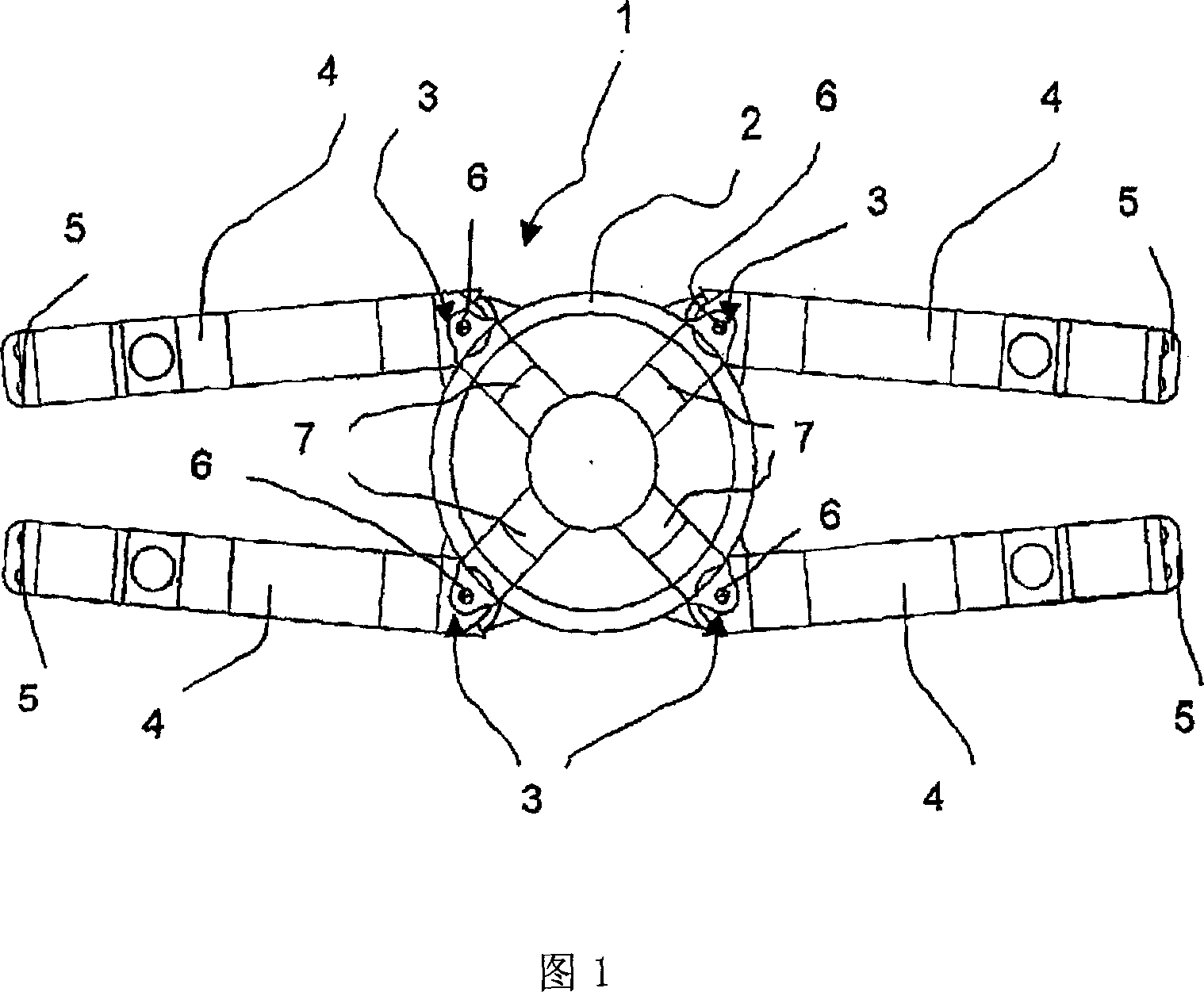

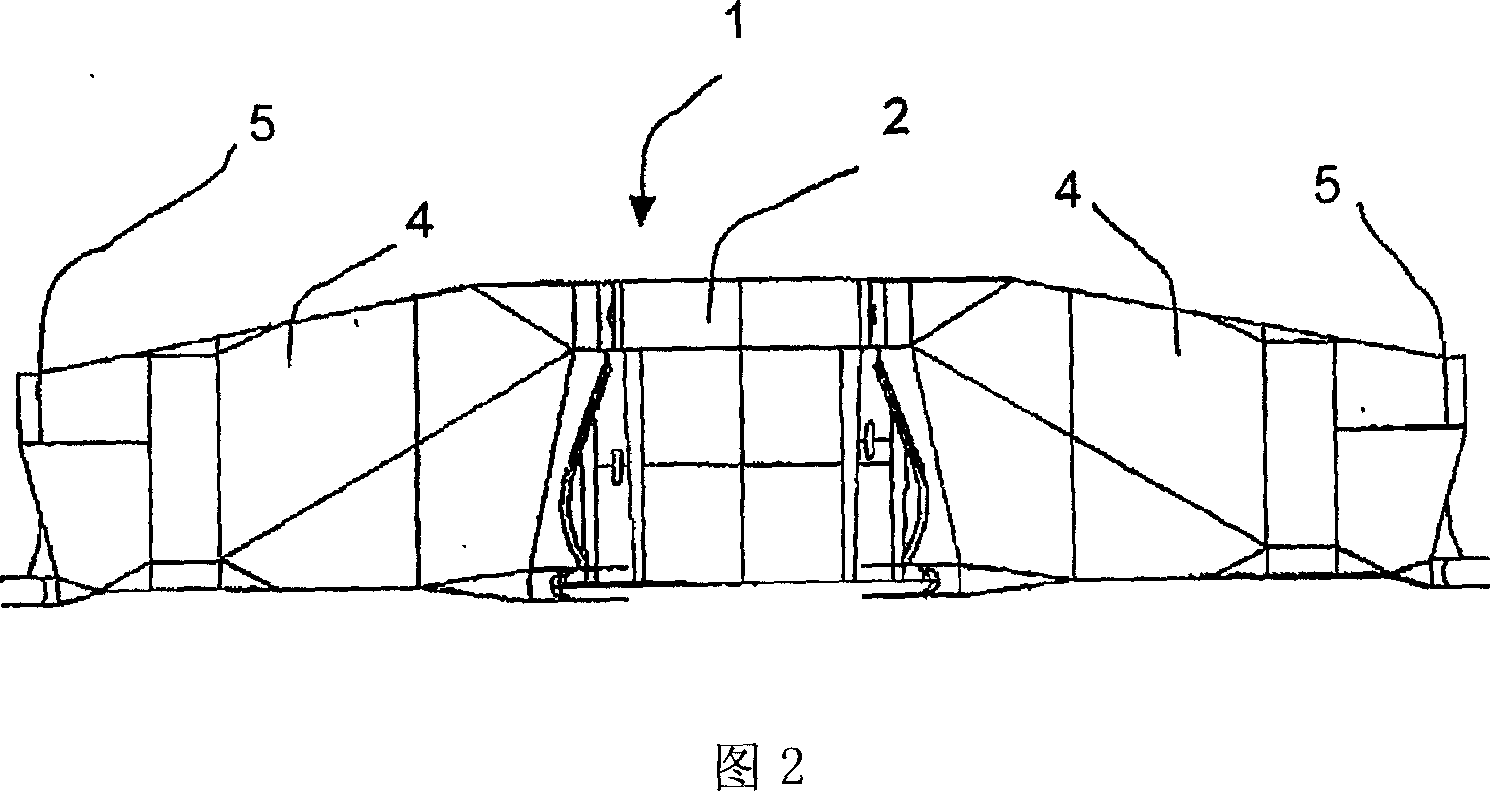

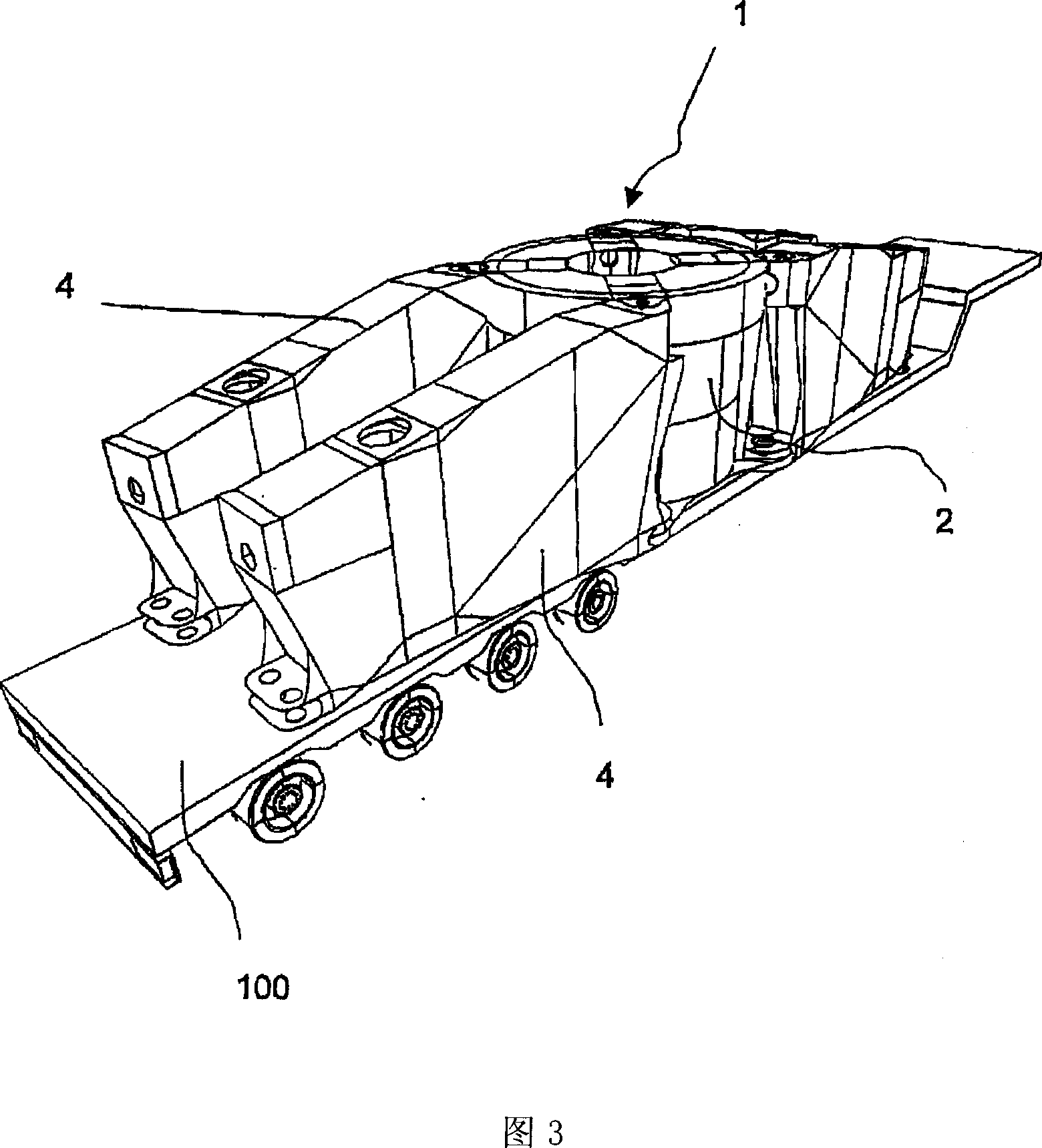

[0032] A first embodiment of the present invention will be described with reference to FIGS. 1-6. As shown in the top view of the crane chassis 1 of the present invention in FIG. 1 , the crane chassis of the present invention comprises a central portion forming a substantially pot-shaped base 2 . The pot-shaped base body 2 has a swivel bearing unit, which is only shown schematically here. A detachable crane superstructure 40 , only shown in FIG. 11 , which is rotatable on the tank-shaped base 2 , is mounted on the swivel support unit.

[0033] Four pivot hinges 3 are all formed on the outer circumference of the tank-shaped base 2 of the crane chassis 1 of the present invention; Outriggers 4. In the particular embodiment of the crane chassis 1 according to the invention shown here, the pivot joints 3 are arranged at a distance of 90° relative to the central axis of the base body 2 . It goes without saying that other angles can also be arranged between the pivot joints 3 . F...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap