Electric connector device applied with elevator bearing member

A technology of load-bearing components and electrical connectors, applied in the direction of conductive connections, connections, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

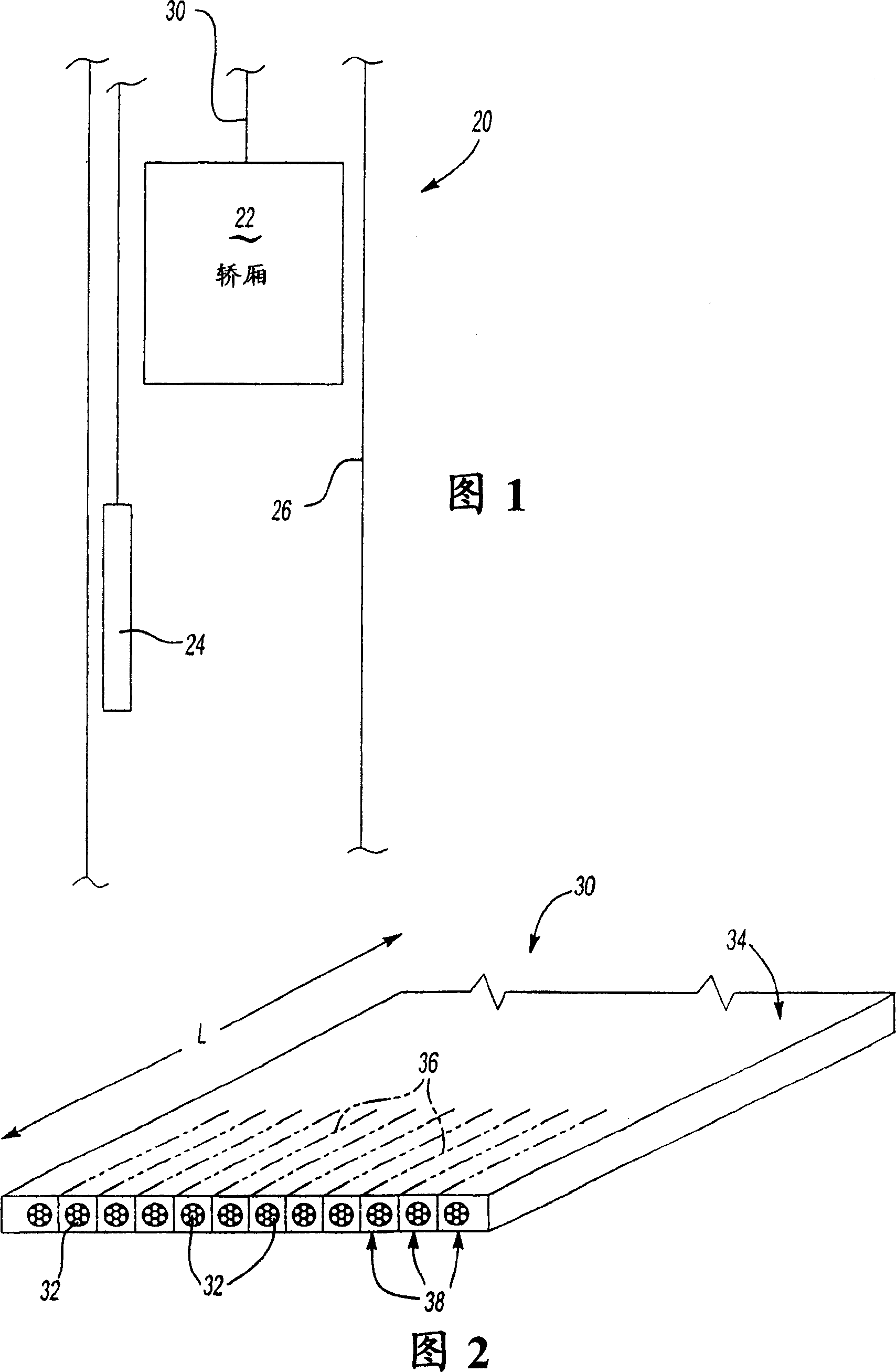

[0020] FIG. 1 exemplarily shows selected portions of an elevator system 20 . The car 22 travels in a shaft 26 with a counterweight 24 in a conventional manner. The load bearing member 30 supports the weight of the car 22 and counterweight 24 and interacts with at least one drive sheave of a machine (not shown) to facilitate the desired movement of the car and counterweight within the shaft.

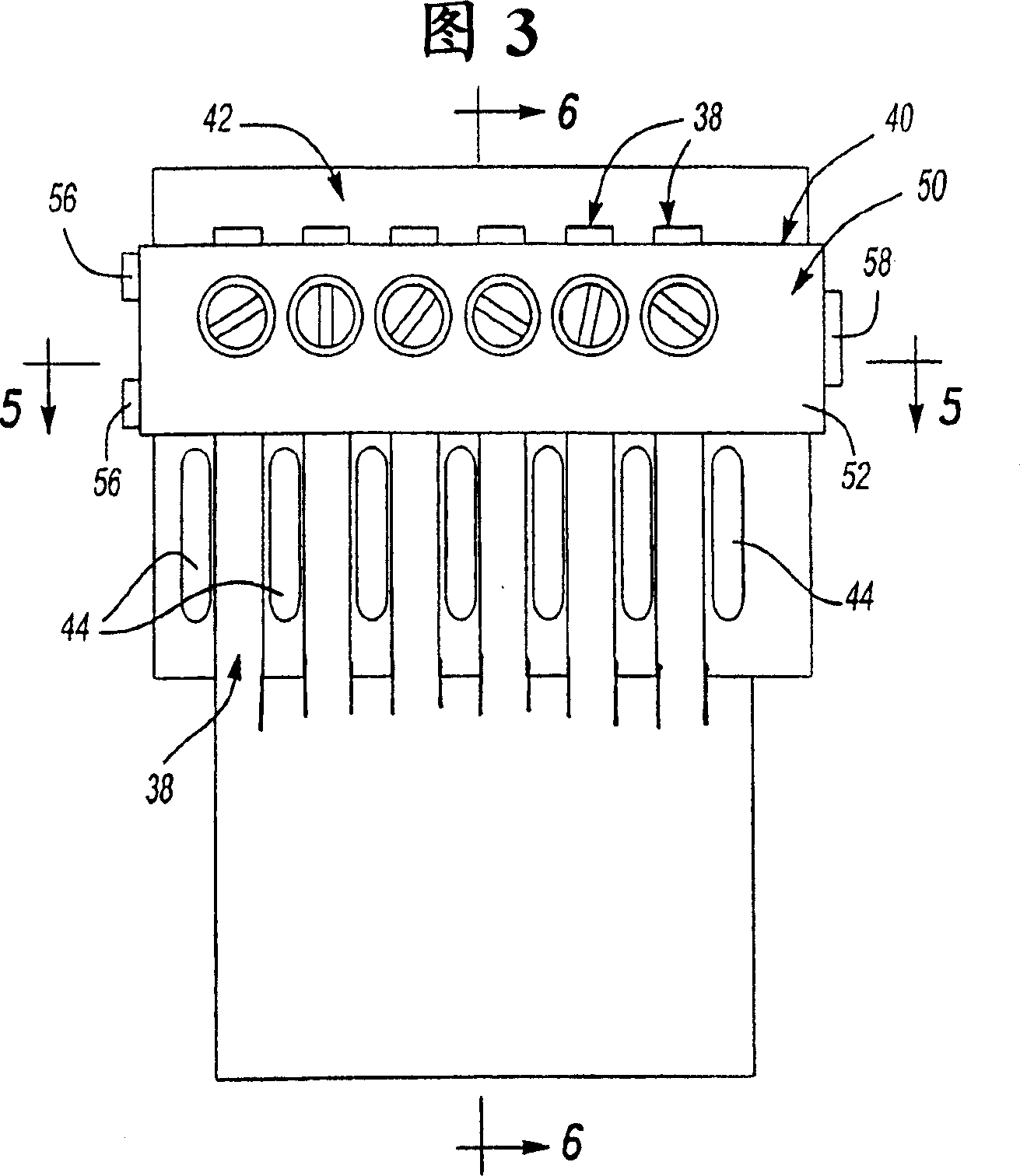

[0021] Figure 2 exemplarily shows a portion of an example load bearing member 30, which is a coated steel strip. The example in FIG. 2 is for purposes of discussion and the invention is not necessarily limited to a particular type of belt or load bearing member. In this example, a plurality of tension members 32 extend longitudinally (ie, the direction L shown in FIG. 2 ) in the belt 30 . In one example, each tension member 32 comprises steel strands wound into wires in a conventional manner.

[0022] The tension member 32 is encased in a sleeve 34 which, in one example, comprises a po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com