Continuously squeezing method and apparatus for expanding extrusion

A technology of extrusion device and extrusion method, which is used in metal extrusion forming tools, metal extrusion, metal processing equipment, etc., can solve the problem of unsatisfactory filling of the four corners of extrusion products, increase equipment operating costs, and restrict equipment specification range, etc. problems, to achieve the effect of increasing the hourly output, improving the service life, and forming a good shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

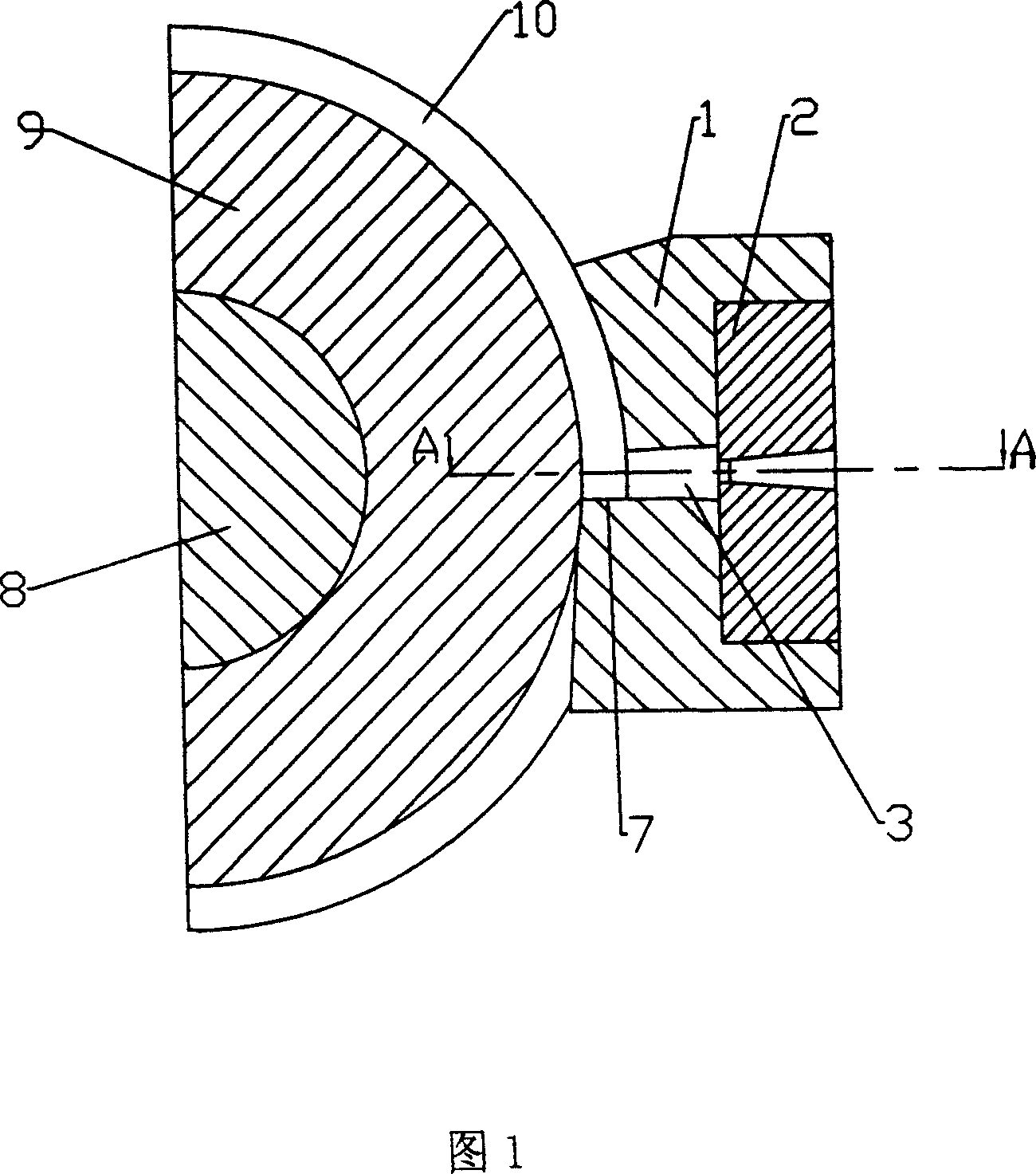

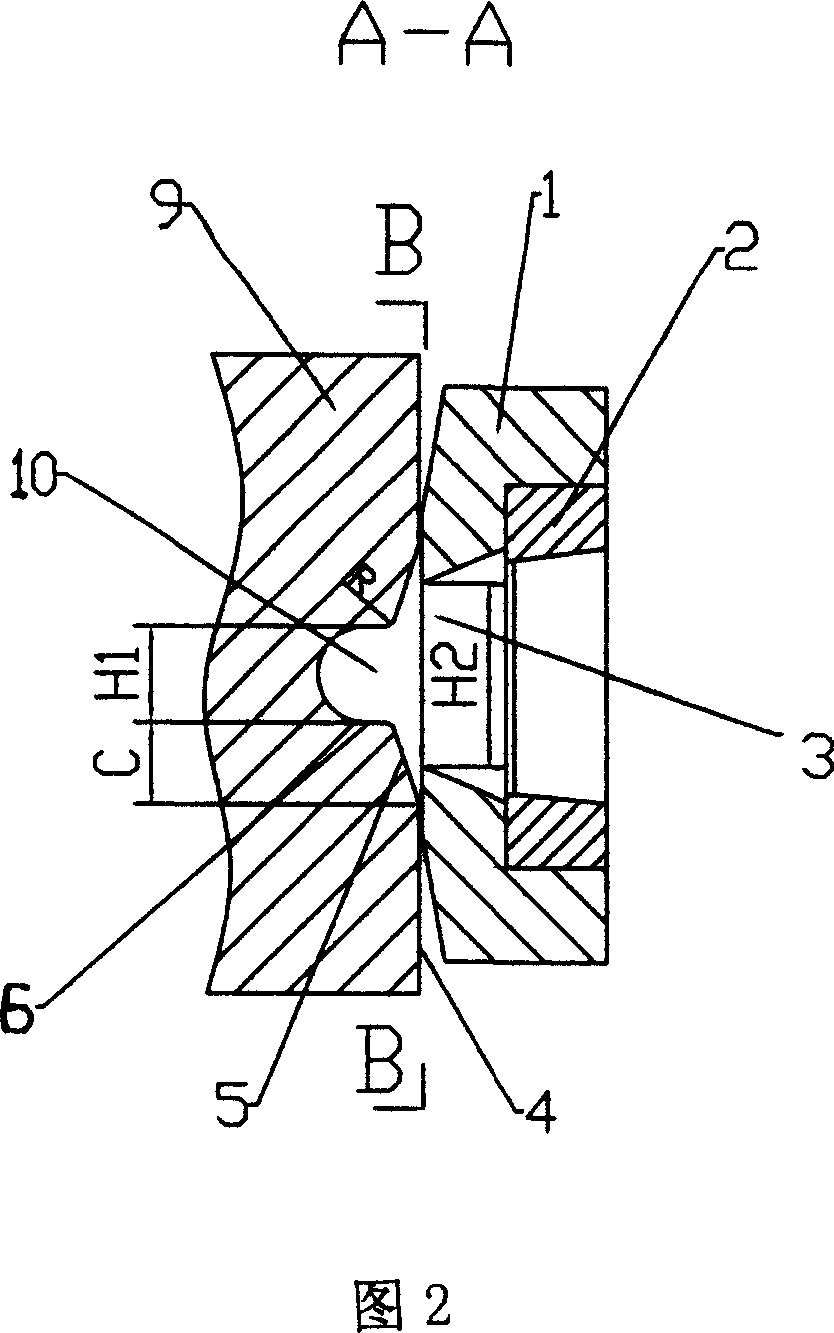

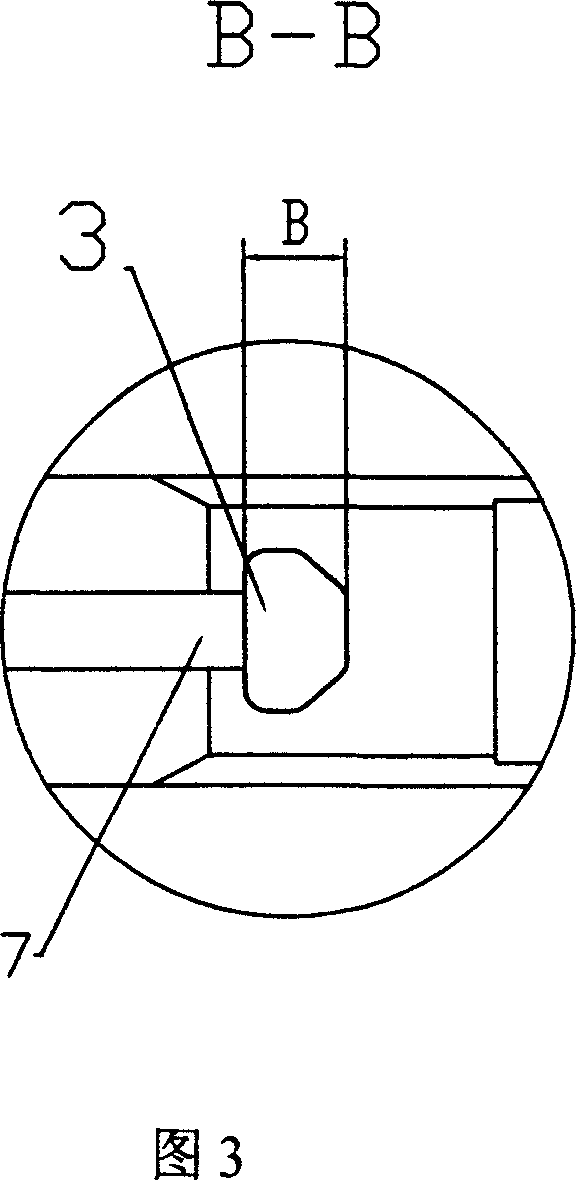

[0016] A continuous extrusion device for extended extrusion used to produce extruded products on continuous extrusion equipment, as shown in Figure 1, includes an extrusion wheel and a mold, and the extrusion wheel with grooves in the circumferential direction is rotatably installed on a rotating shaft 8 , there is a stop block 7 on one side of the cavity, a billet feed port is arranged in the middle of the cavity, a mold 2 is installed on the cavity below the feed port, and the width of the groove 10 on the extrusion wheel 9 is H1, the cavity The width dimension of the feed opening 3 on the 1 is H2, and the dimension H2 is obviously increased, so that H2 is greater than the width H1 of the groove 10 of the extrusion wheel 9 plus twice the fillet radius, that is, H2>H1+2R. The length dimension B of the feed opening 3 is greater than 1.6 times the width dimension of the groove 10 . The cross-sectional shape of the feed port 3 of the cavity 1 can be any shape. As shown in Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com