Fiber reinforced heating unit and mattress with thereof

A fiber-reinforced, heating device technology, applied in the direction of electric heating devices, ohmic resistance heating, heating element materials, etc., can solve the problems of overheating, non-heating, agglomeration, etc., and achieve the effect of preventing entanglement and preventing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

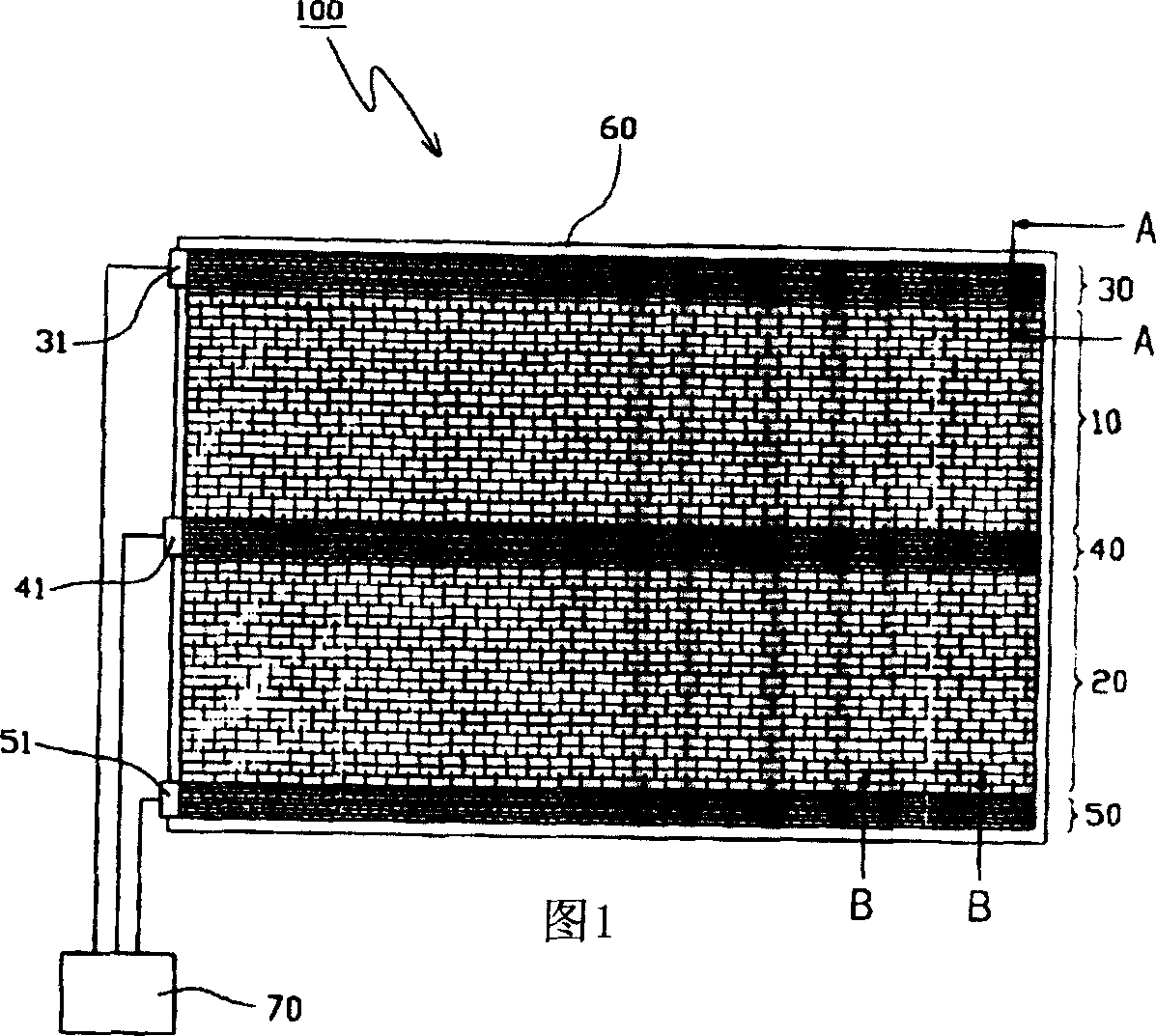

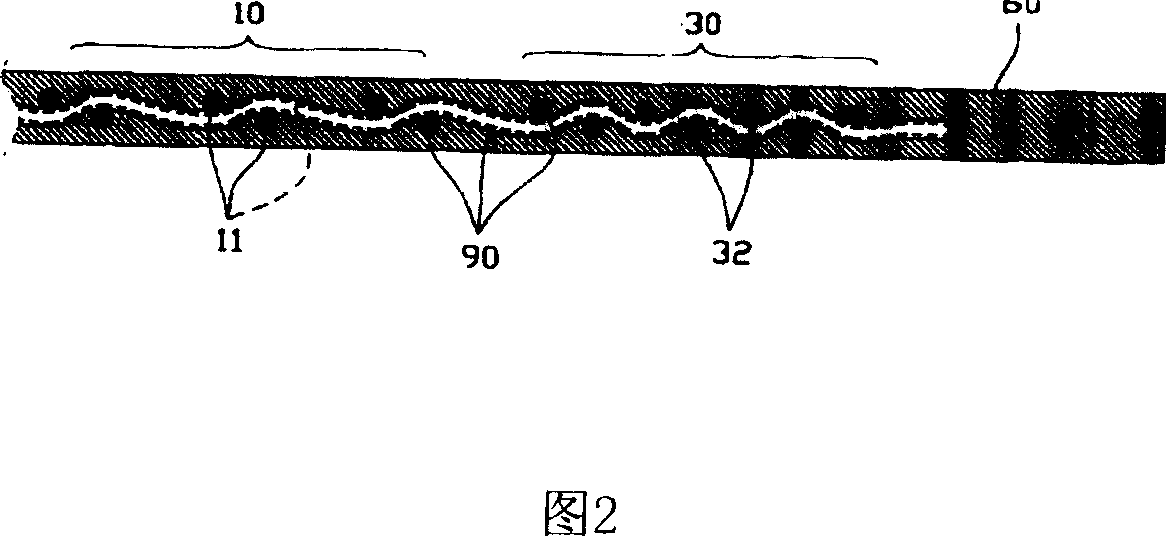

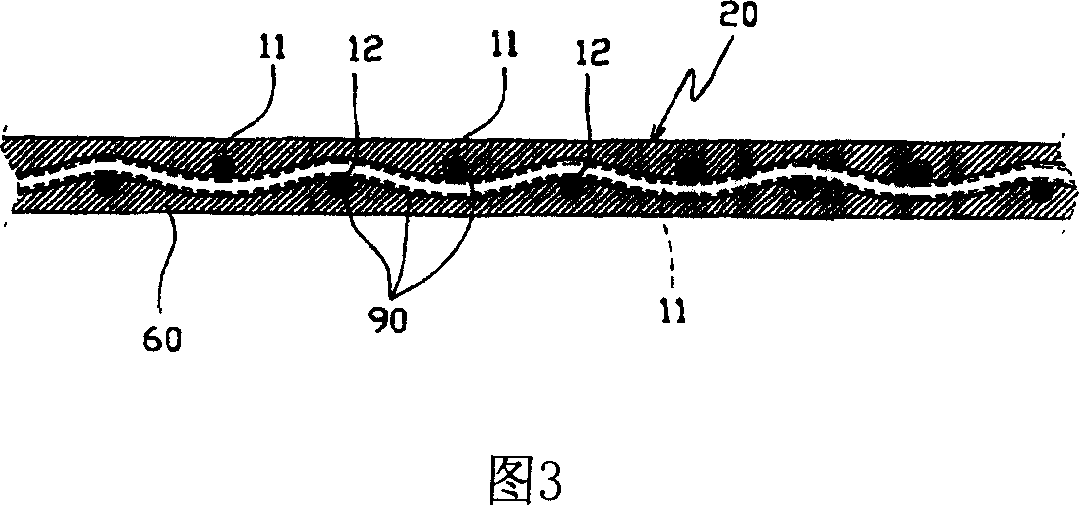

[0023] FIG. 1 is a plan view of a heating device according to an embodiment of the present invention.

[0024] Referring to FIG. 1, a heating device 100 according to the present invention comprises: a net woven vertically and horizontally using flexible filaments, the size of which is suitable for installation in the entire area of a mattress; a pair of electrode portions 30, 50 on the longitudinal edges, which It is formed by braiding several copper wires and flexible filaments, and the central electrode part 40 is formed by braiding several copper wires and flexible filaments.

[0025] In a preferred embodiment, the pair of electrode portions 30, 50 are connected to the positive (+) terminals 31, 51, the centrally disposed electrode portion 40 is connected to the negative (-) terminal 41, and the positive (+) ) terminals 31, 51 and negative ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com