Cutting tool and method for cutting material

A technology for cutting materials and tools, applied in milling cutters, manufacturing tools, twist drills, etc., can solve the problems of insufficient pit accuracy and impossible to provide, and achieve the effect of reducing mechanical stress, vibration and wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

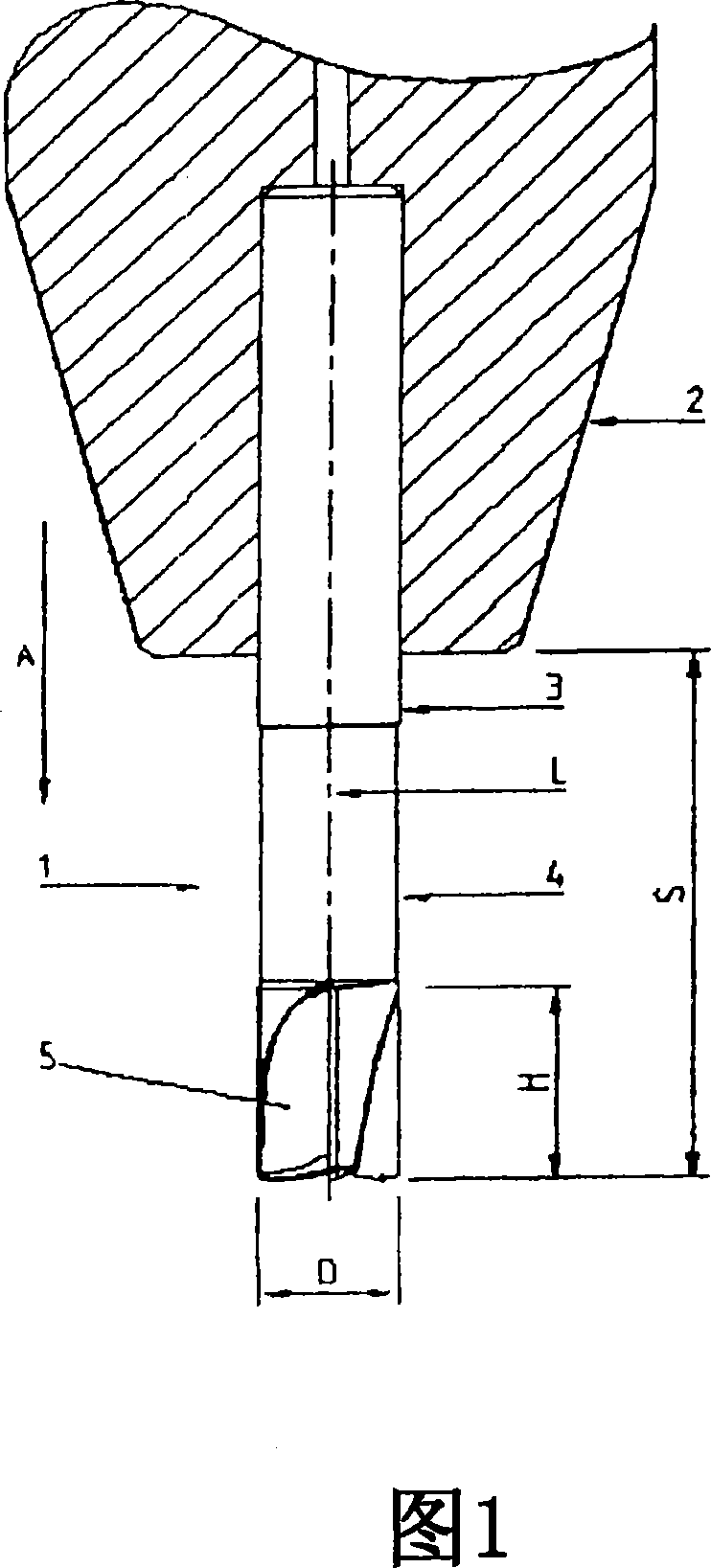

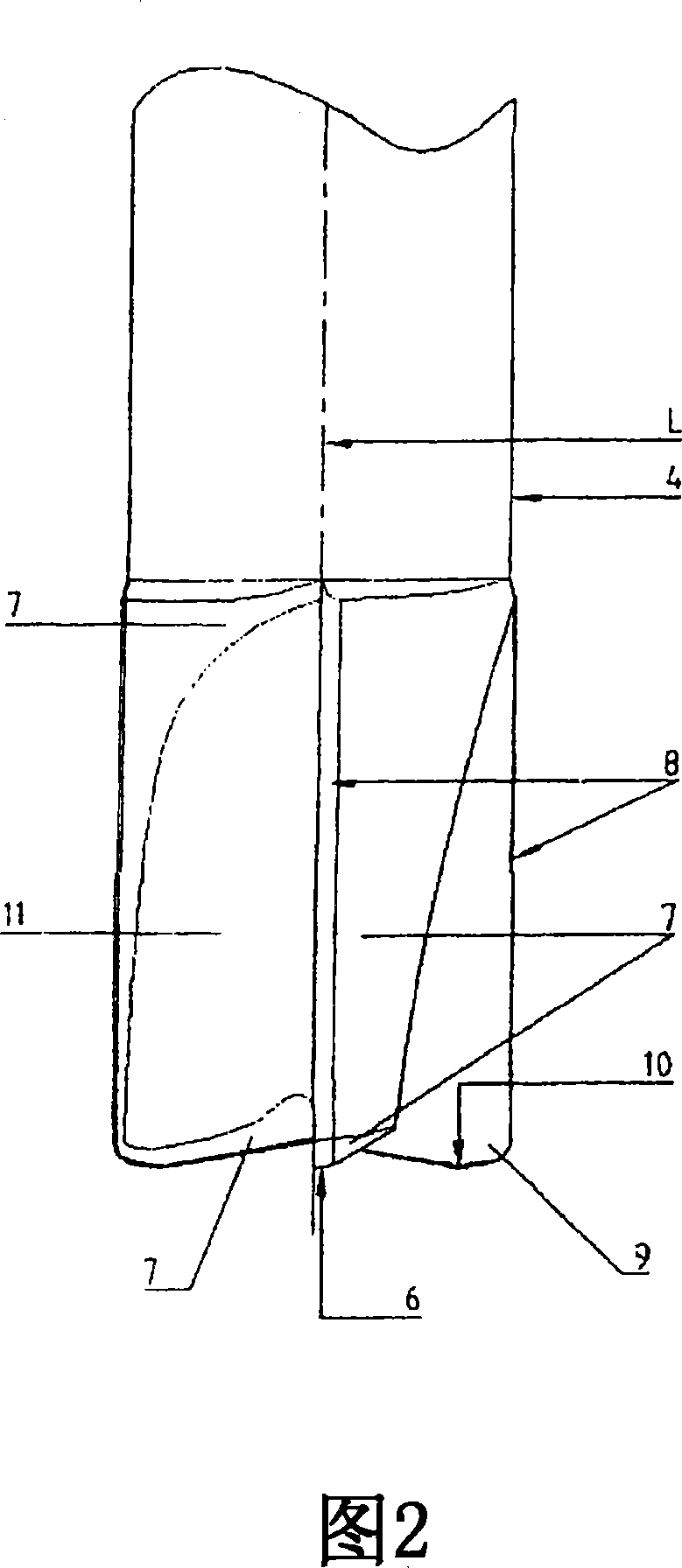

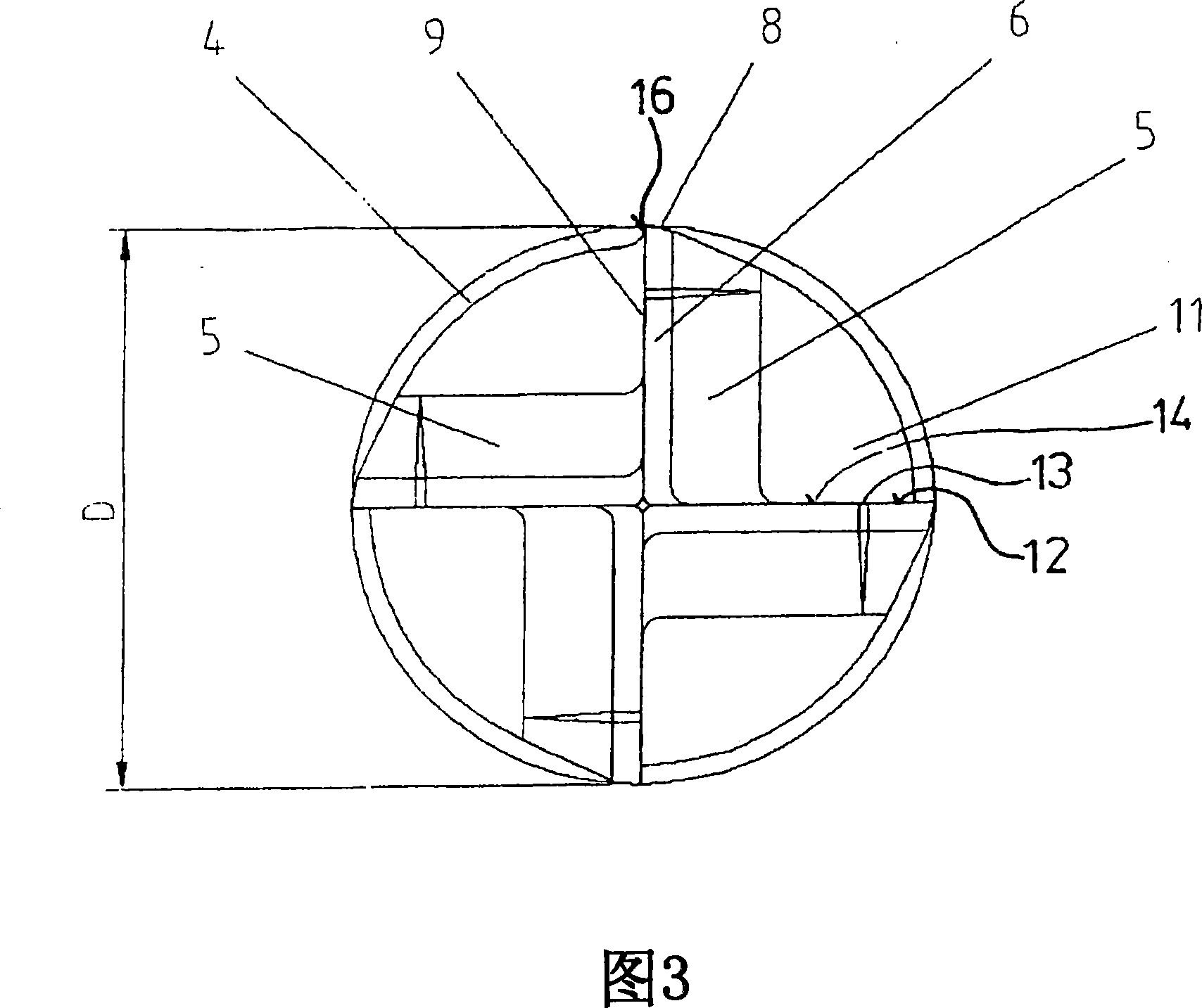

[0033] 1 , 2 and 3 show a cutting tool 1 clamped in a tool holder 2 with a clamping surface 3 . The tool holder 2 is part of a numerically or conventionally controlled machine tool and can position and move the cutting tool towards the part to be machined. In use, the cutting tool 1 is rotated at a rotational speed about an axis of rotation L and is fed at a feed rate A in a feed direction into the material to be cut. The cutting tool 1 is provided with cutting teeth 5 which are connected to the clamping surface 3 via the shank 4 . The number of cutting teeth can vary and generally ranges between two and five, preferably four. The cutting teeth 5 have a cutting diameter D and a cutting height H. On the side remote from the tool holder 4 , ie on the underside, the cutting tooth 5 has a cutting edge 10 for cutting material. Since the cutting edge 10 is at the end of the cutting tool 1, such a tool is also called an end mill. At the periphery, the cutting tooth 5 has a suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com