Branched well selective guiding in tool

A tool-introducing and selective technology, applied in directional drilling, wellbore/well components, earth-moving drilling, etc., can solve the problems of difficult completion and workover operations of lateral wells, complicated construction procedures, and high risks, reducing the Construction risk, simplified construction process, reliable work effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0007] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS: The following will be described in conjunction with the accompanying drawings.

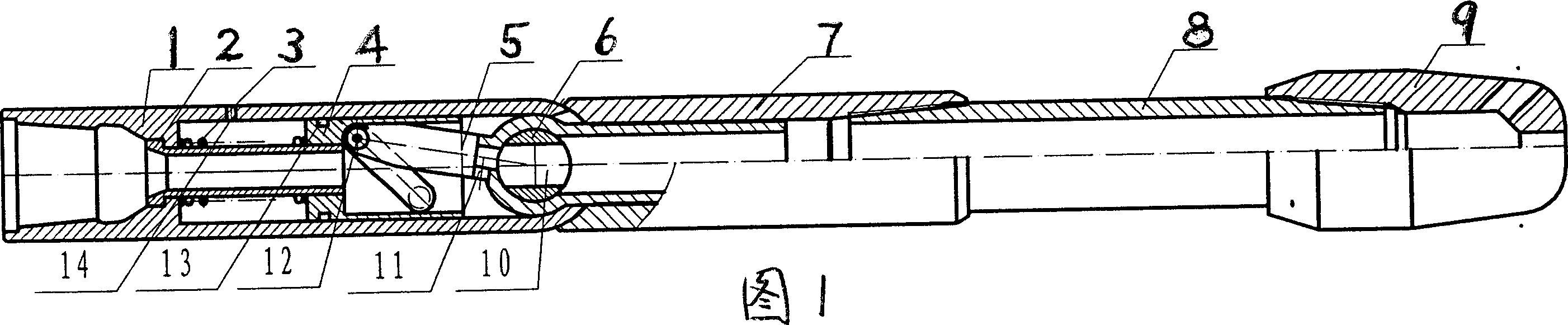

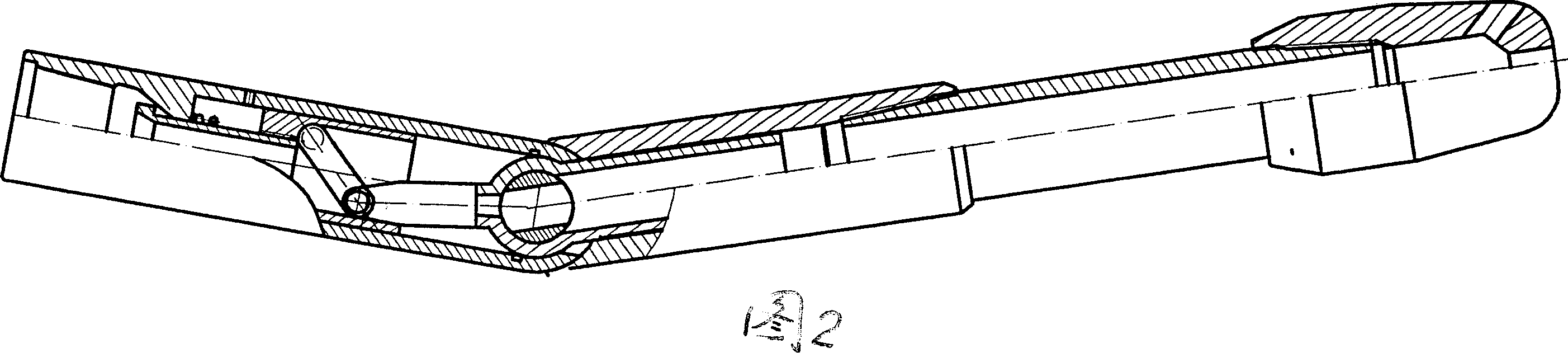

[0008] As shown in the figure: the branch well selective introduction tool used in the present invention consists of an upper casing 1, a central rod 2, a spring 3, a sliding sleeve 4, a crankshaft 5, a fixed pin 6, a guide head 7, a connecting rod 8, and a guide shoe 9 , sliding pin 12, and sealing ring 13, and its connection and assembly relations are as follows: a central rod 2 is arranged in the cavity of the upper housing 1, and the upper end of the central rod 2 is placed on the upper side of the inner circular surface boss of the upper housing 1, and the lower end is externally threaded It is connected with the internal thread at the upper end of the sliding sleeve 4, and a spring 3 is installed between the upper housing 1 and the sliding sleeve 4; a sealing ring 13 is installed in the upper sealing ring groove on the outer surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com