Deficient pole shotblast cleaning method and apparatus

A technology of shot blasting and anode residue, which is applied in the direction of used abrasive processing devices, abrasive jetting machine tools, abrasives, etc., can solve the problems of difference in cleaning quality of anode residue, irregular shape of anode residue, and less contact surface, etc. Achieve the effects of low equipment maintenance workload, solving unclean cleaning, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

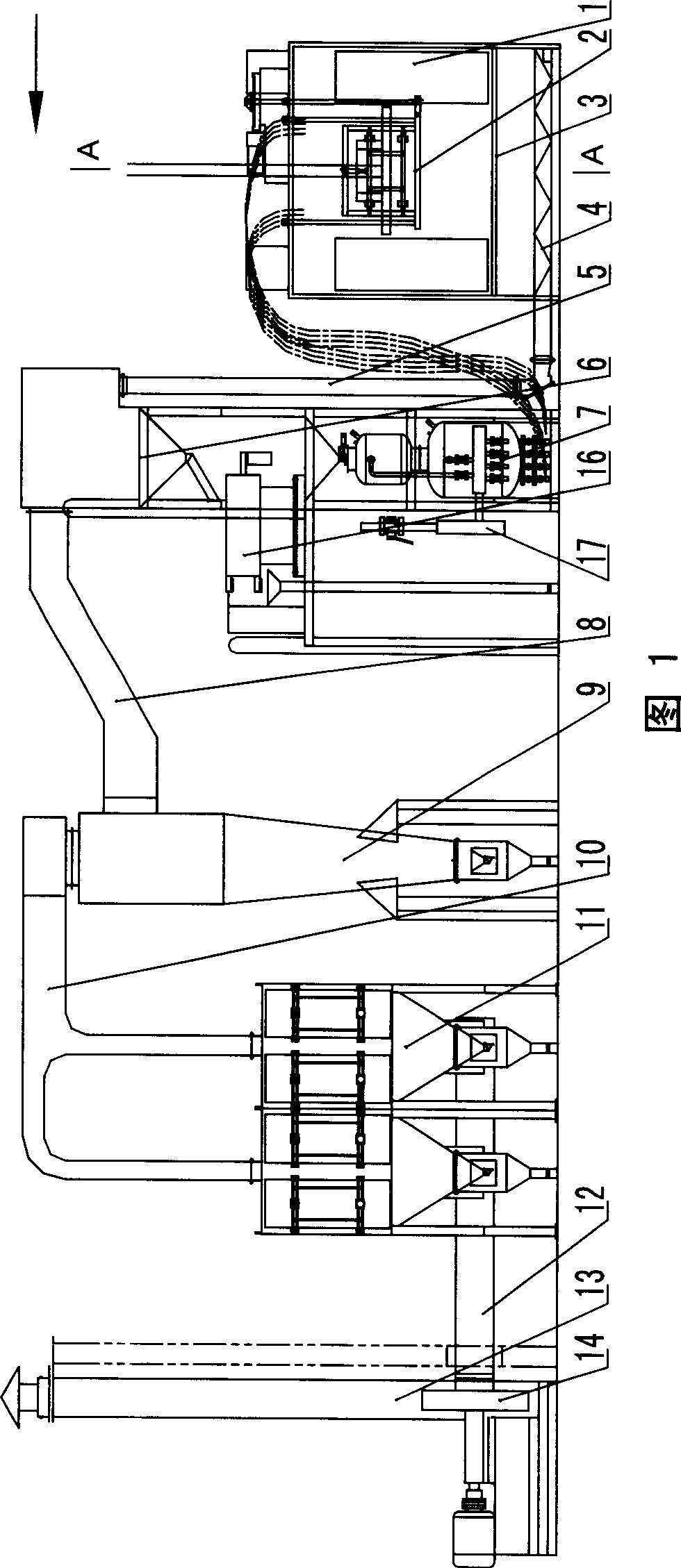

[0057] Embodiments of the invention:

[0058] First, manufacture the shot blasting chamber 1, and adopt the following mechanisms:

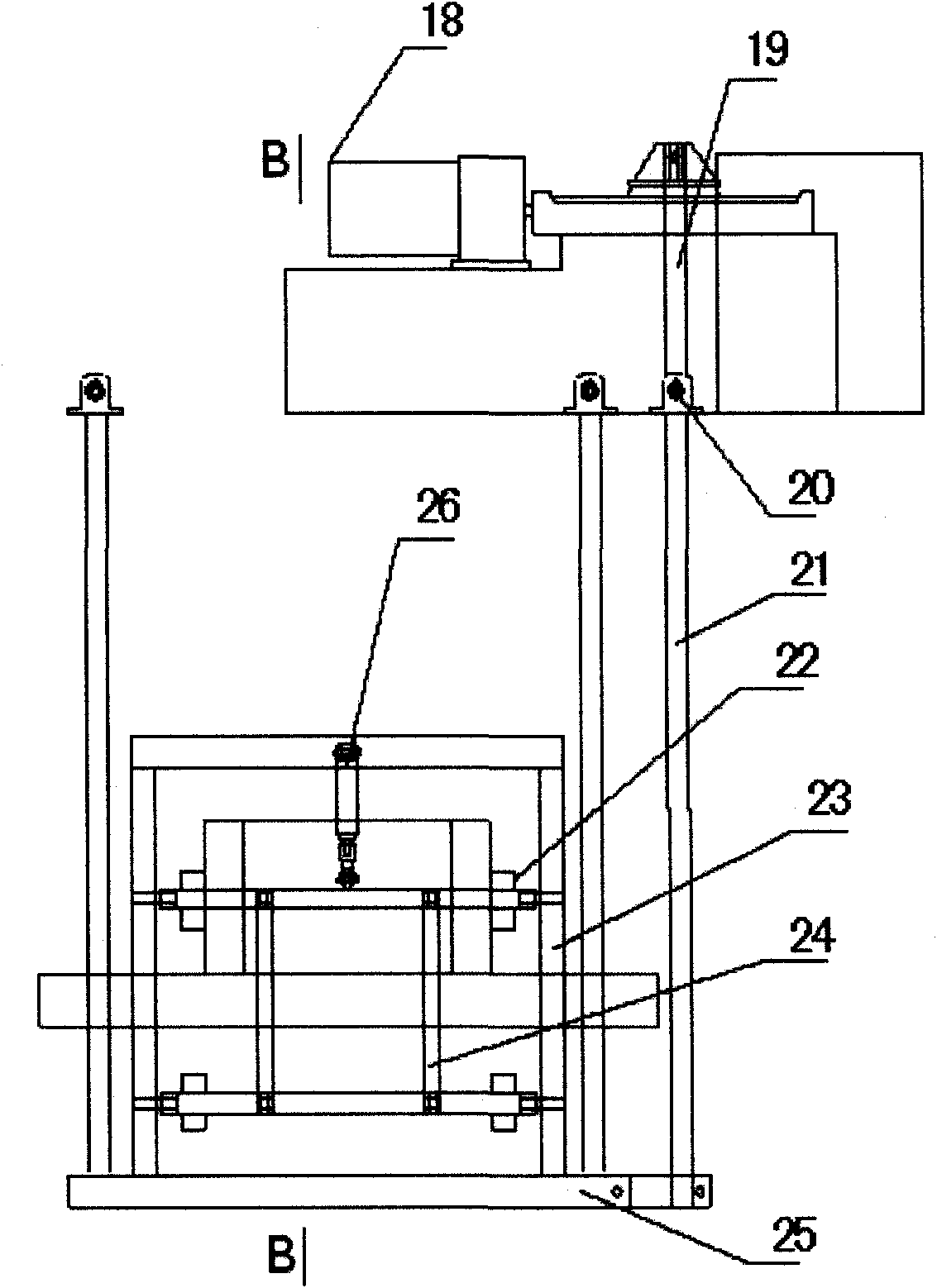

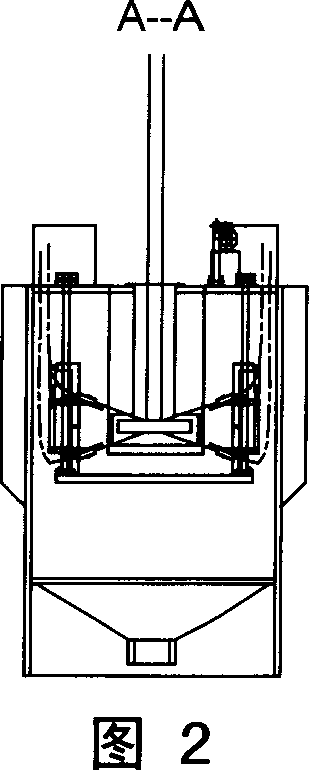

[0059] ①Automatic shot blasting swing mechanism, choose and buy motors and bearings, make eccentric wheels and various brackets, and assemble them according to the diagram. Connection, the rocker arm bracket 21 is connected with the connecting bracket 25, there is a bracket 23 on the connecting bracket 25, the bracket 23 is connected with the swing bracket 24, the ear plate 28 of the spray gun 22 is connected with the bracket 23, and the eccentric wheel 30 is connected with the fixed pin 29 Connect, the eccentric wheel 30 is connected with the swing bracket 24, and the two ends of the swing cylinder 26 are connected with the bracket 23 and the swing bracket 24 respectively.

[0060] 8 spray guns are connected to the automatic swing mechanism, 4 on each side, including 2 on the upper part and 2 on the lower part.

[0061] Wherein, the motor 19 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com