Coaxial multi-detection-point detecting rod

A technology of multi-measuring points and test rods, which is applied in the field of precision measurement, can solve the problems that test rods and retractable metal probes cannot solve the multi-point test of the same part, and achieve the effect of eliminating measurement errors and ensuring measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

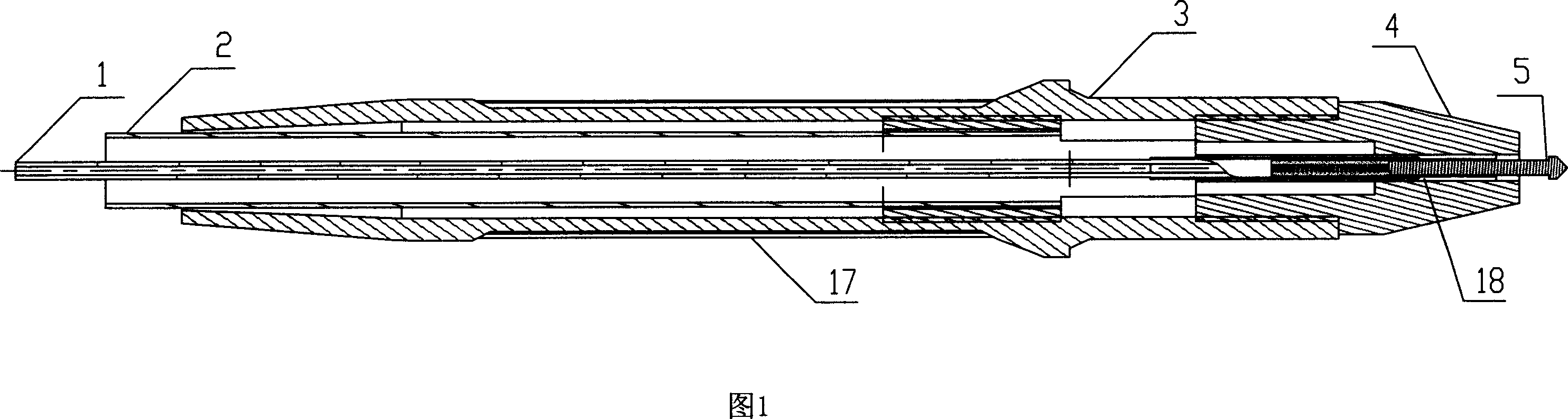

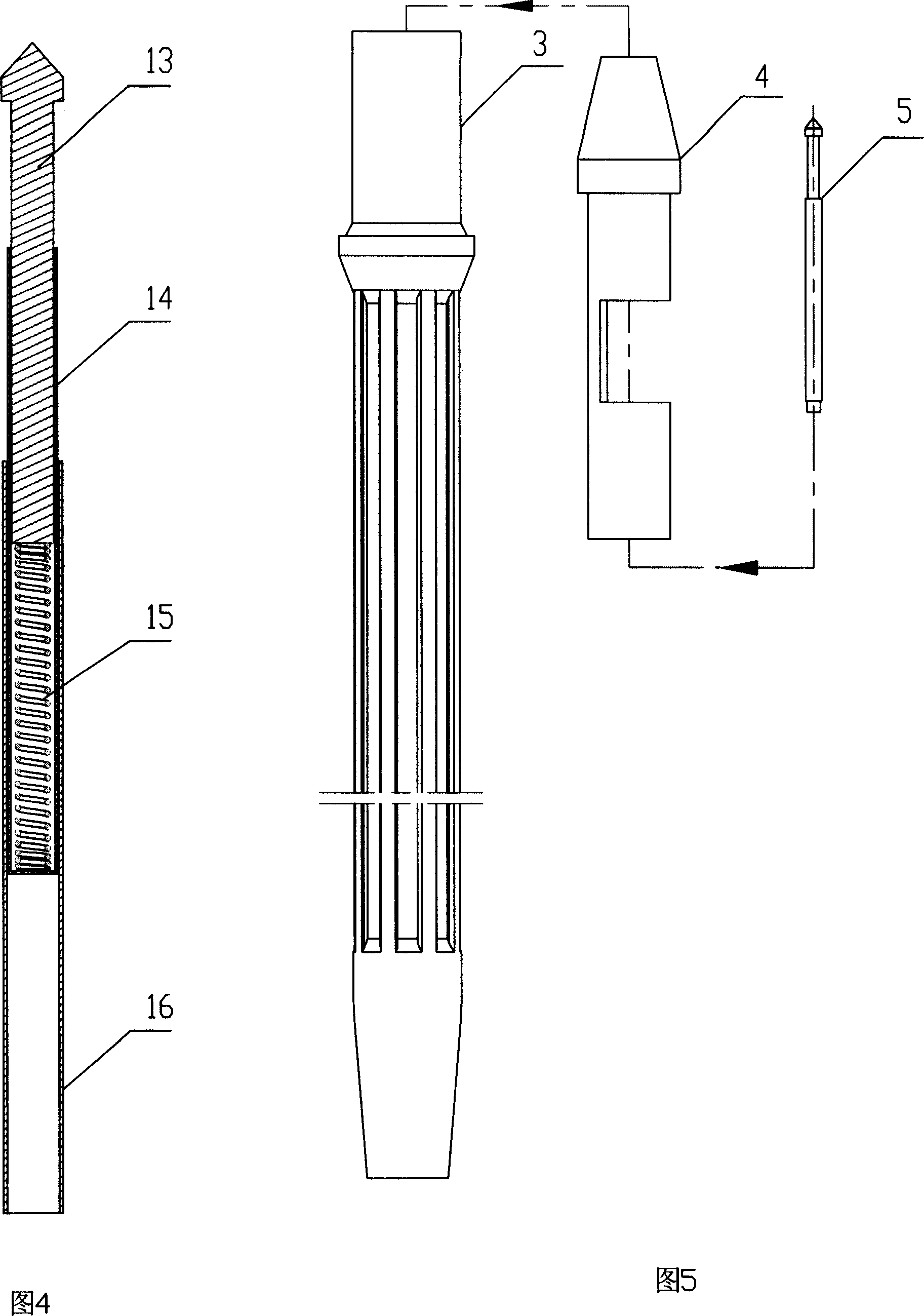

[0027] Referring to FIG. 1 , the coaxial multi-point test rod of the present invention is provided with a telescopic metal probe 5 at the axis of the insulating casing 3 , and a coaxial metal probe 4 is provided around the telescopic metal probe 5 . The signal of the stretchable metal probe 5 is drawn out from the terminal connecting lead 1 , and the signal of the coaxial metal probe is drawn out of the terminal connecting lead 2 . An insulating layer of epoxy resin 18 is provided between the stretchable metal probe 5 and the coaxial metal probe 4 .

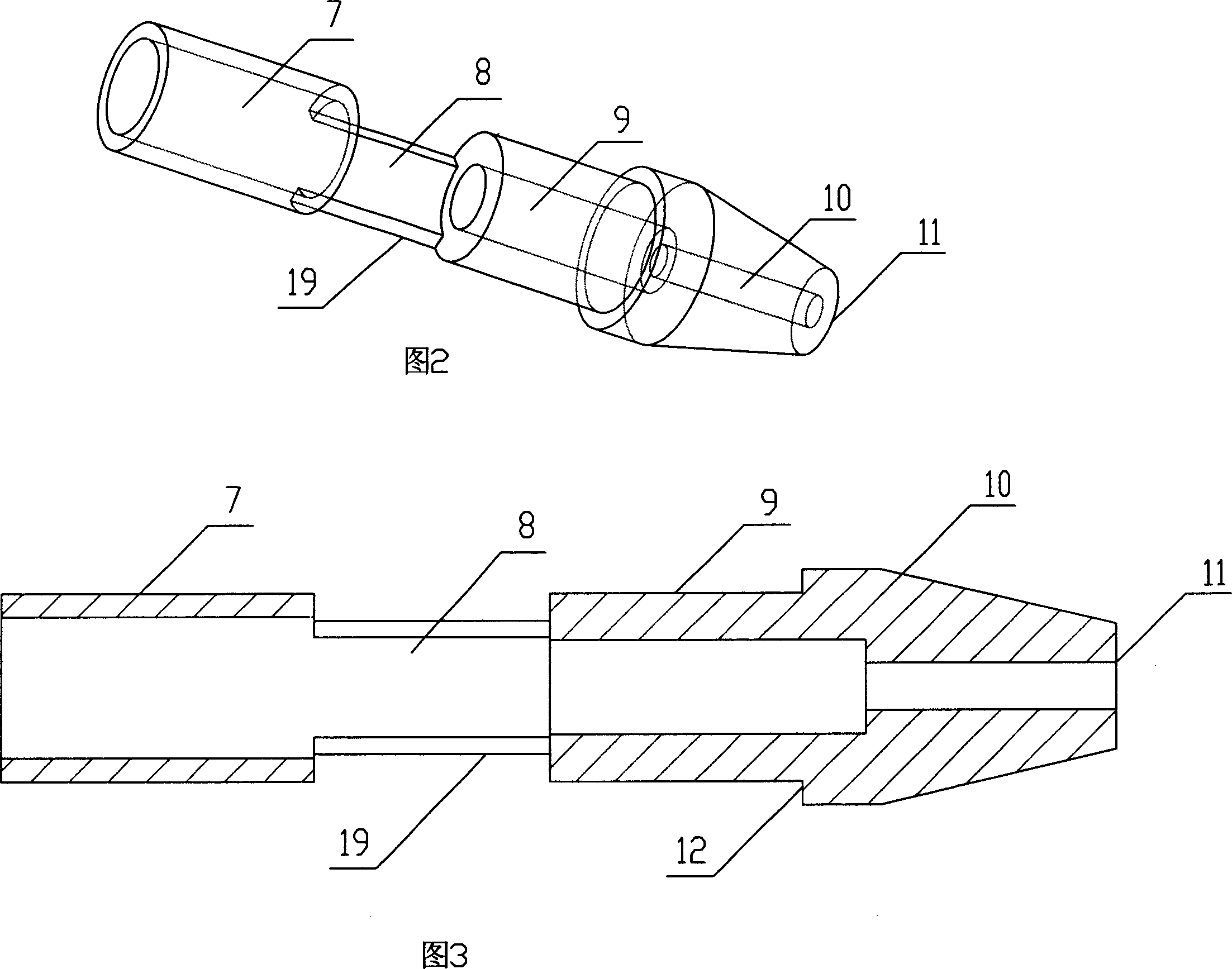

[0028] Referring to Figures 2 and 3, the coaxial metal probe 4 is in a tubular shape and is composed of five sequentially connected functional parts. The first functional part is a test end face 11, and the second functional part 10 is a truncated cone-shaped end. The cavity is used for installing the retractable metal probe 5 . The third functional part 9 is in the shape of a round tube, and a positioning notch 12 is formed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com