On-line oil-filtering apparatus of loaded tap changer

A technology of on-load tap changer and oil filter device, which is applied in the direction of transformers, electrical components, variable inductors, etc., can solve the problems of numerous structural layouts of pipelines, influence on appearance, and many pipe joints, etc., and achieve compact structural layout, Easy to seal and reduce the effect of sealing parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

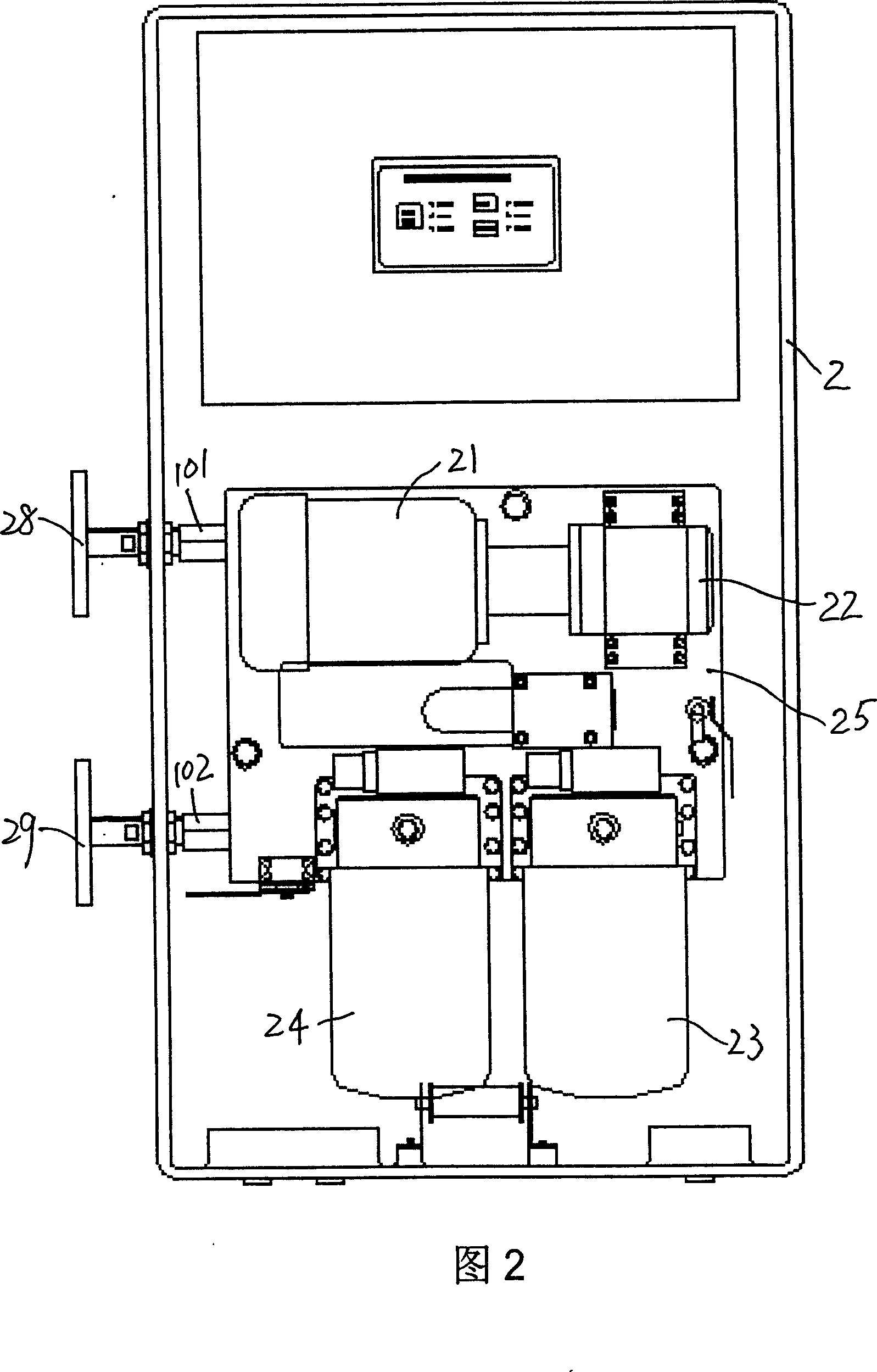

[0019] See Figure 2. The on-line oil filter device for on-load tap changer of the present invention comprises: a case 2, a motor 21 disposed in the case, an oil pump 22, an impurity removal filter 23, a water removal filter 24, and a pipeline integration board 25.

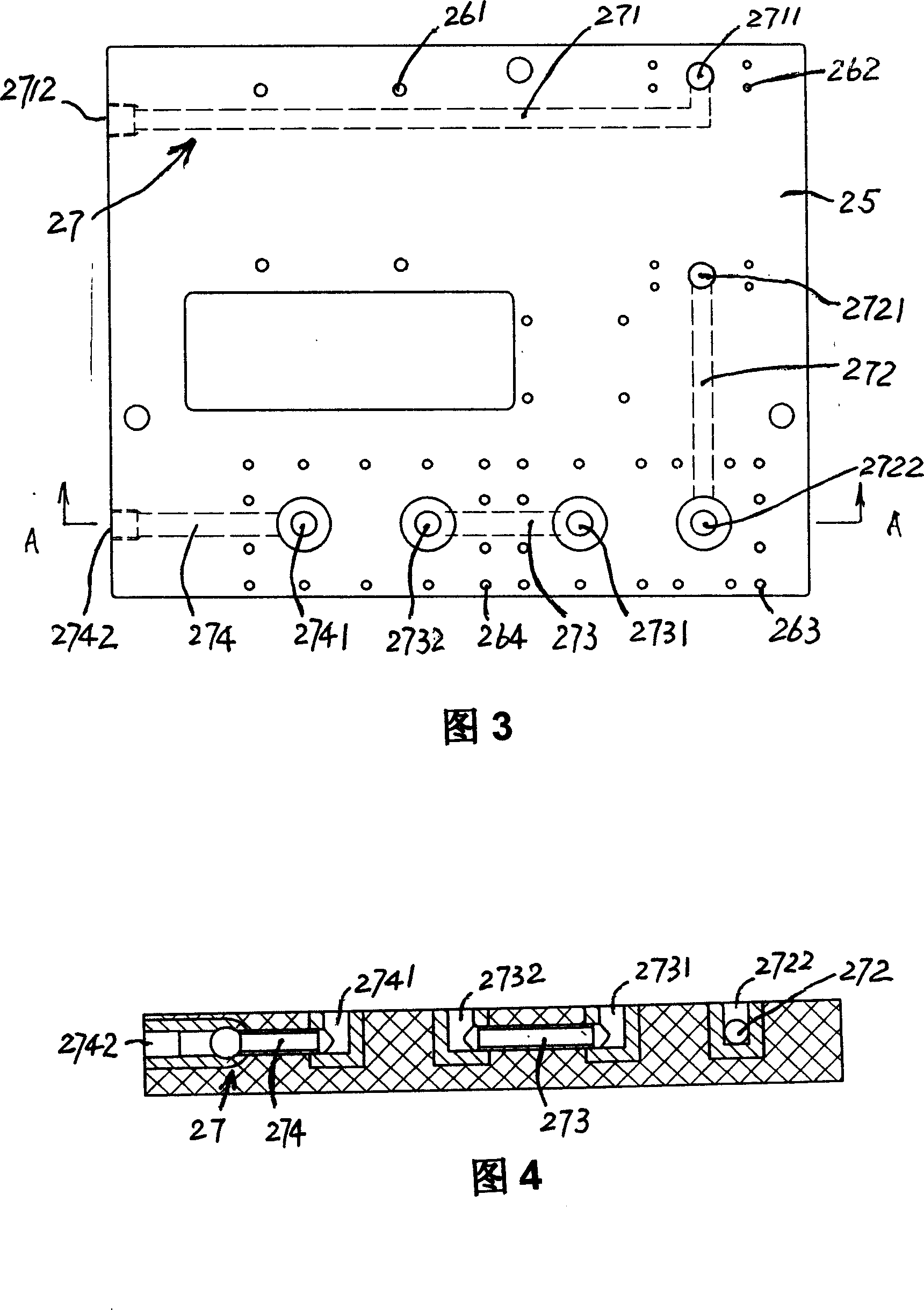

[0020] Please refer to Figure 3 and Figure 4. The pipeline integration plate 25 includes a plate body 251, a plurality of connecting pipelines 27 buried in appropriate positions in the wall of the plate body, and connecting holes provided on one side of the plate wall to communicate with the respective connecting pipelines. The connecting pipeline 27 can be formed by embedding the pipeline inside the board wall of the integrated board or adopting a method in the board wall formed by molding. This connecting line is shown in dashed lines in FIG. 3 and in cross-sectional view in FIG. 4 . The connecting pipeline 27 includes an oil inlet pipe 271 , a first connecting pipeline 272 , a second connecting pipeline 273 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com