Integration of a delta-p expansion valve for COP-optimal regulation in a high-pressure connection, in particular an internal heat exchanger

A technology for expansion valves and parts, applied in lighting and heating equipment, transportation and packaging, thin material handling, etc., can solve the problems of reducing the sealability of coolant circulation, increasing assembly costs and material costs, and achieve the effect of rapid assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

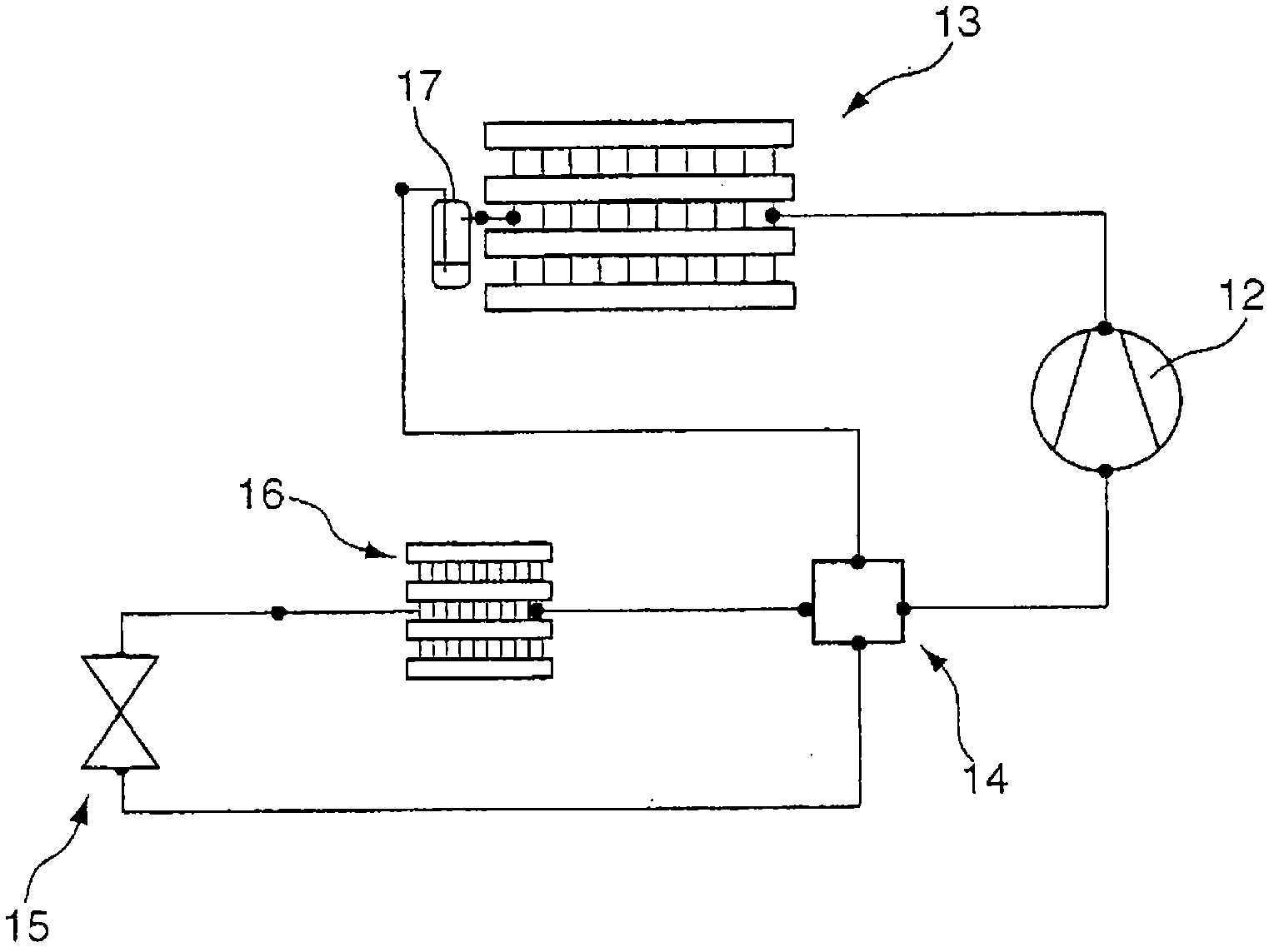

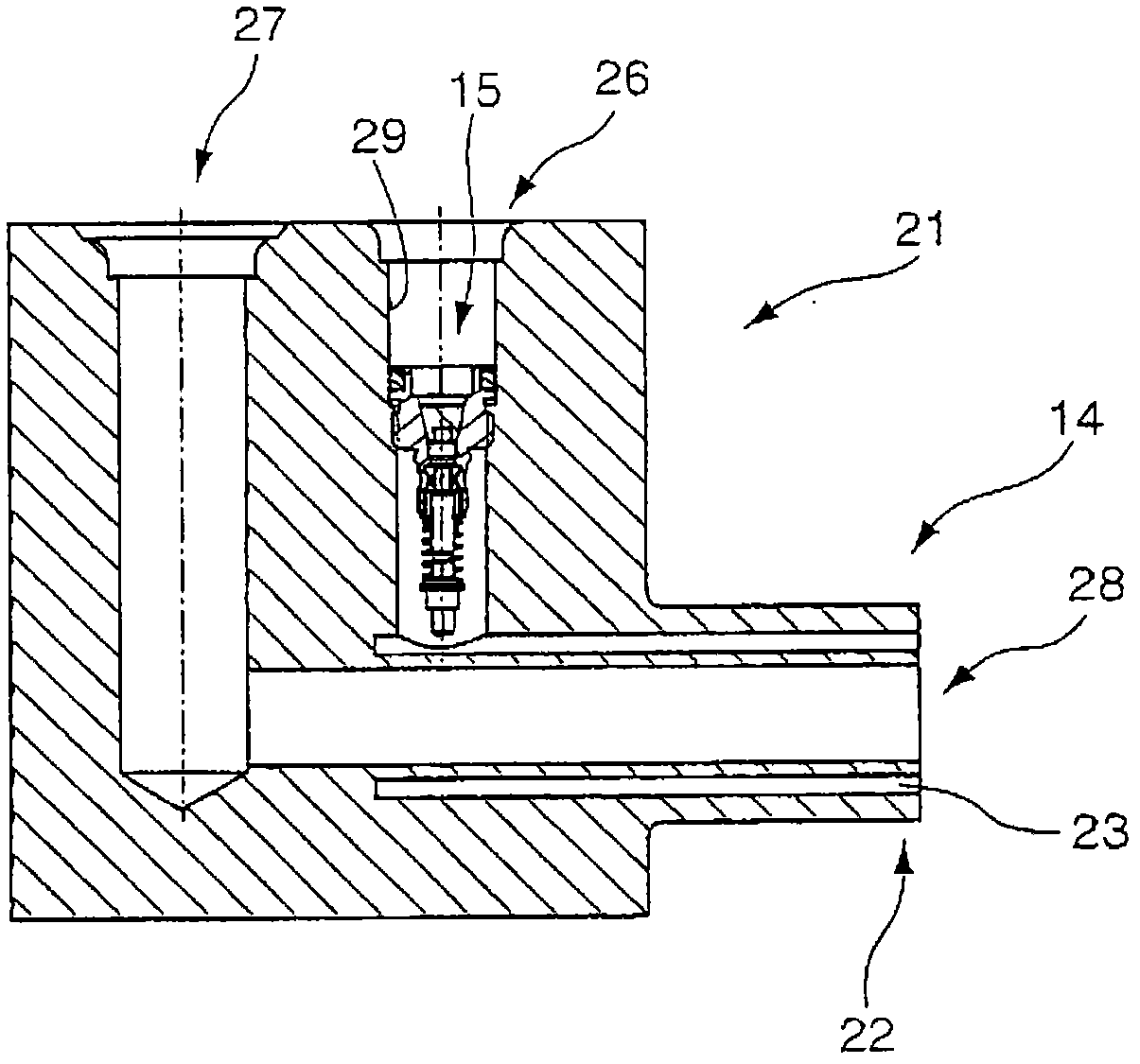

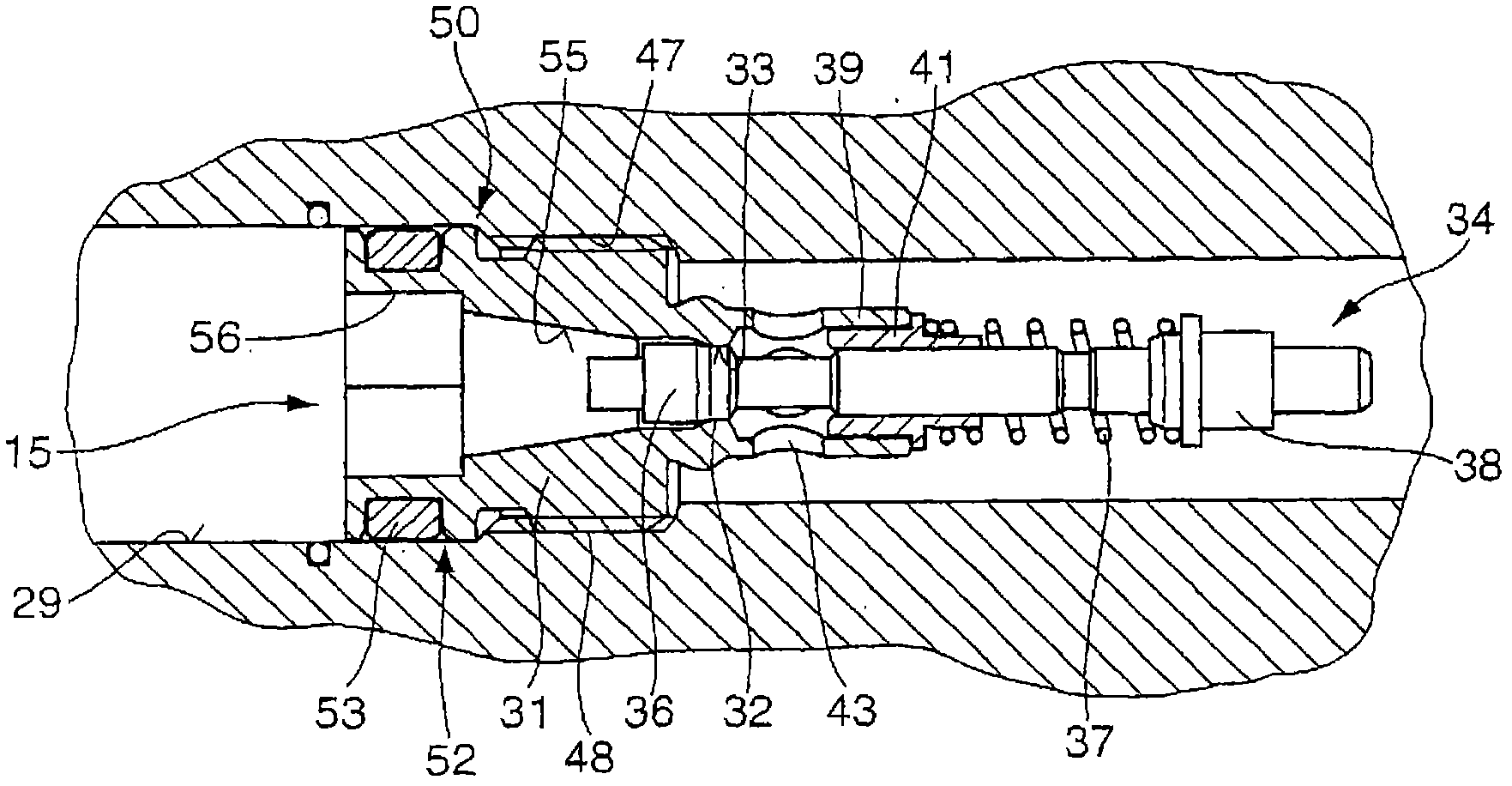

[0030] figure 1 The cold cycle and / or the heat cycle 11 of an air conditioner installed in a motor vehicle in particular is shown. In the refrigerant compressor 12, gaseous refrigerant (especially R134a) is compressed. The compressed coolant is sent to the condenser 13 where heat exchange between the compressed coolant and the environment is carried out in order to cool the coolant. An accumulator 17 may be provided downstream of the condenser 13 in order to separate the refrigerant in the gas phase and the liquid phase and collect the liquid phase refrigerant at the same time. The coolant leaving the condenser 13 or the accumulator 17 reaches the internal heat exchanger 14. An expansion valve 15 is provided between the internal heat exchanger 14 and the evaporator 16. Through the expansion valve 15, the mass flow of the air conditioner is adjusted depending on the existing (anliegend) pressure difference. The coolant reaches the evaporator 16 from the expansion valve 15. I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com