Wire electric discharge machine

A discharge motor and wire diameter technology, which is applied in the direction of circuits, electric processing equipment, metal processing equipment, etc., can solve the problem of not being found, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

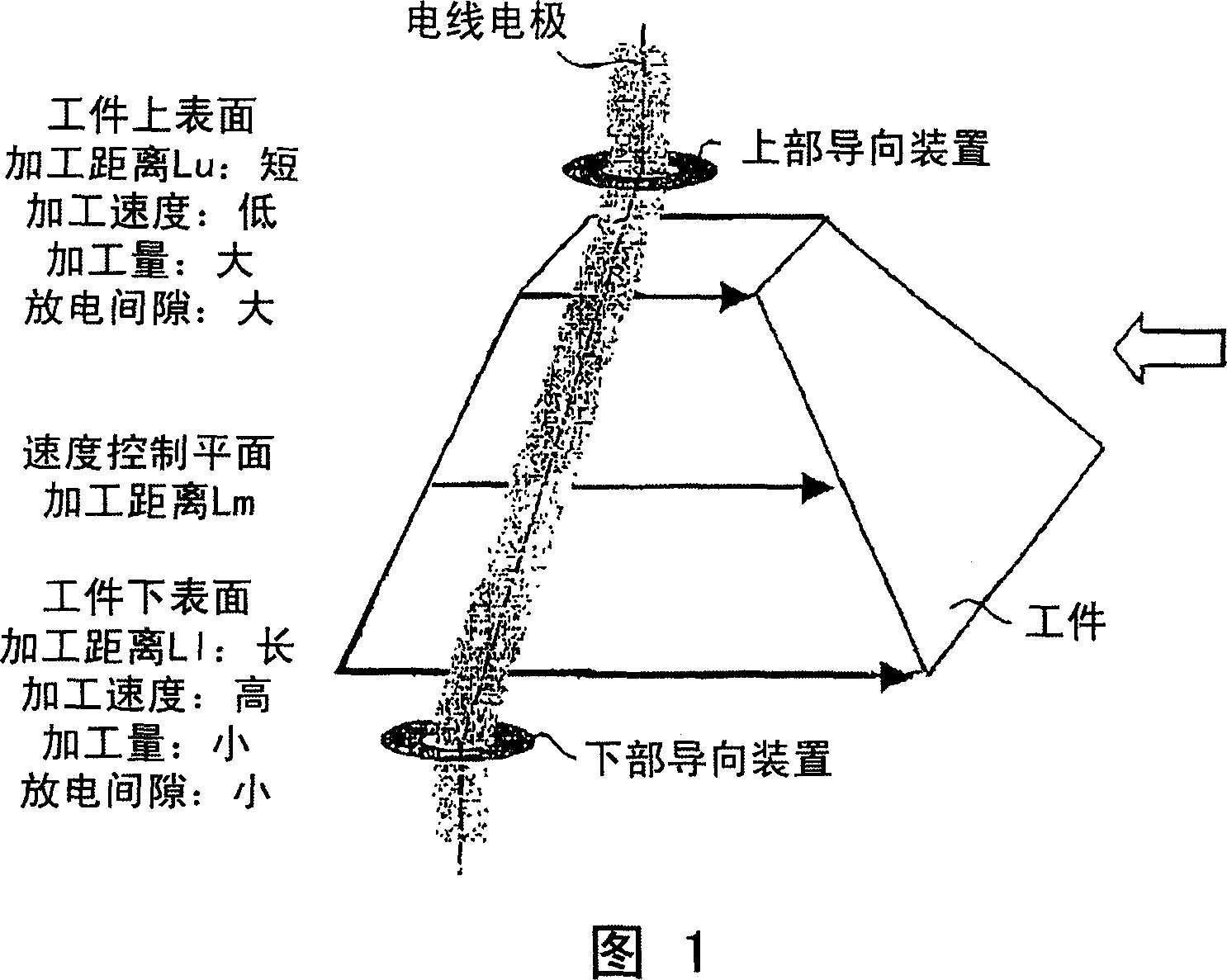

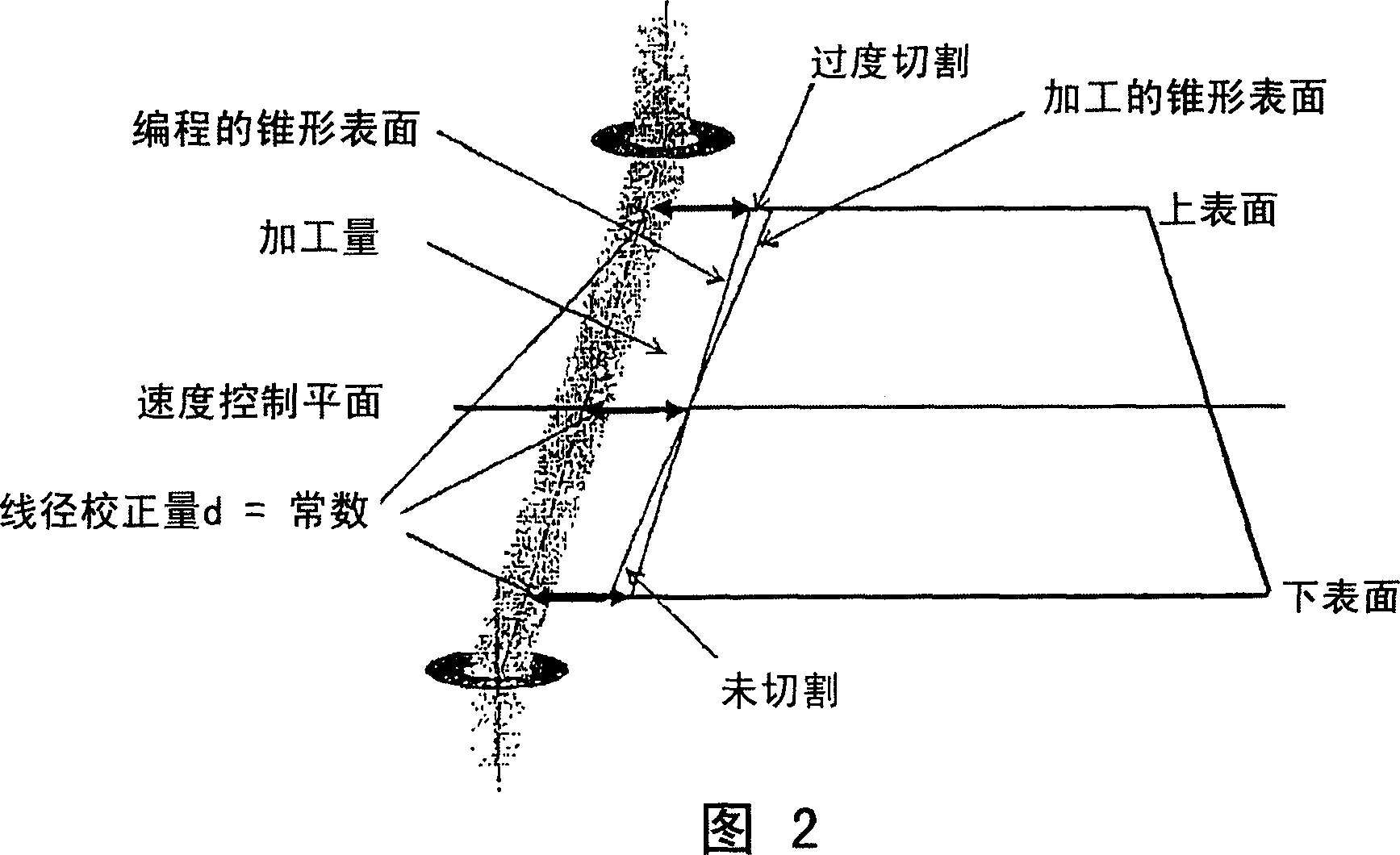

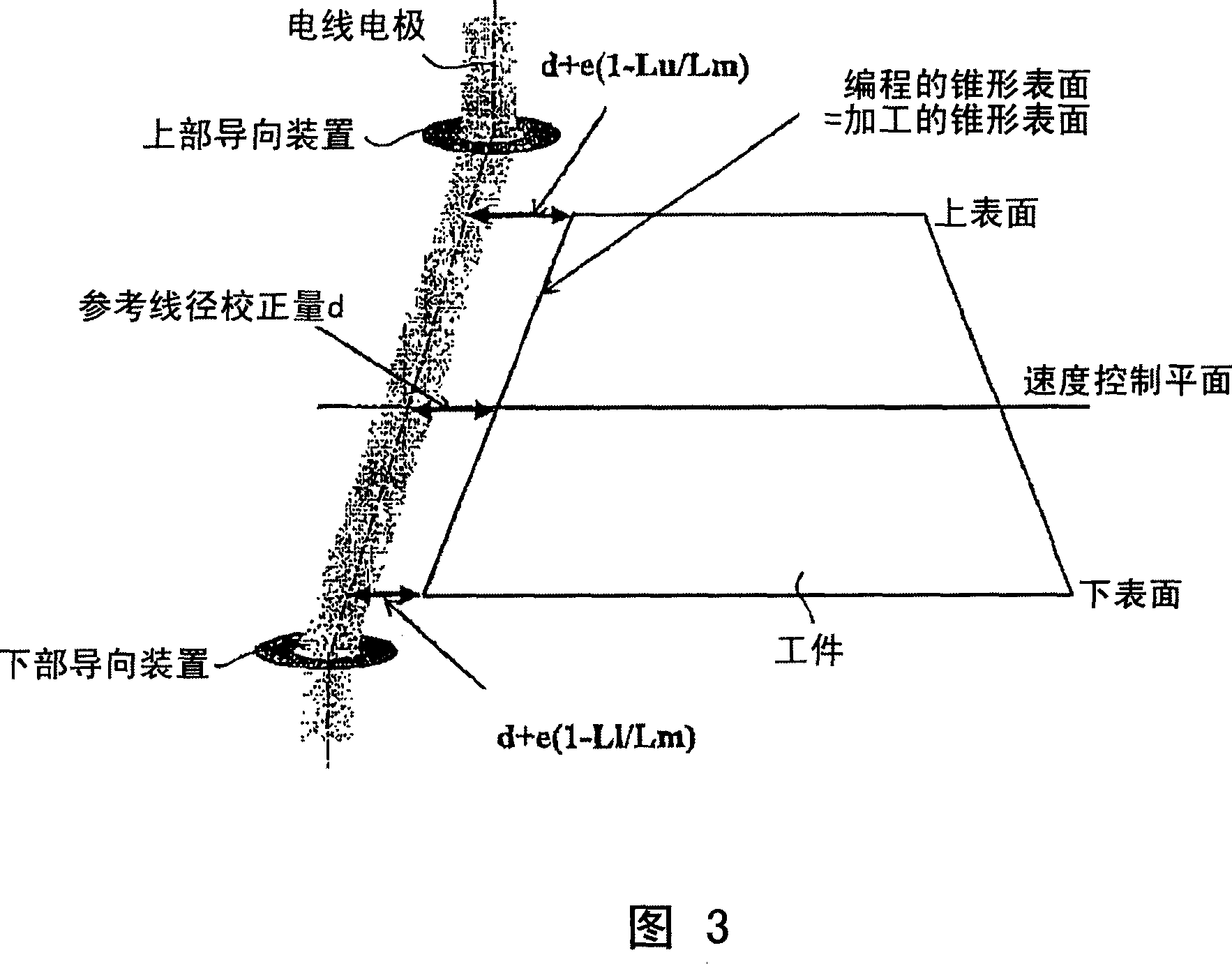

[0032] First, referring to Fig. 4, the schematic structure and operation of a wire discharge machine to which the present invention can be applied will be described. The basic structure of the wire discharge machine shown is the same as conventional. In particular, reference numeral 1 denotes a workpiece setting table for setting and fixing a workpiece 3 to be processed, having an upwardly facing setting surface 2 that is flat with high precision. In processing, the workpiece 3 is set and fixed on the workpiece setting table with its bottom surface in contact with the setting surface 2 .

[0033] In the workpiece 3 , the entire upper surface (upper surface) 31 is parallel to the bottom surface (lower surface) 32 . Here, a cubic-shaped workpiece 3 is exemplified so that the entire upper surface 31 is parallel to the bottom surface 32 . However, the workpiece 3 can be such that only the upper part is parallel to the bottom surface. Reference numeral 4 denotes a wire electrode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com