Process for separating meta-xylene from a feed of aromatic hydrocarbons

一种间二甲苯、分离方法的技术,应用在分离方法、弥散粒子分离、吸附纯化/分离等方向,能够解决费用高、蒸馏分离困难等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0096] In this example, a breakthrough test (head chromatography) was carried out, evaluating the operating conditions described in US 4 306 107, i.e. using an adsorbent with a loss on ignition (assessed at 500°C) of 2.3% and an adsorption temperature of 120°C , and then according to the operating conditions described in US 5 900 523, that is, using an adsorbent with a loss on ignition (assessed at 500°C) of 1.75%, and an adsorption temperature of 125°C, to separate m-xylene from m-xylene / ortho-xylene mixture efficiency.

[0097] The composition of the material is as follows:

[0098] - m-xylene: 45% by weight:

[0099] - o-xylene: 45% by weight;

[0100] - Isooctane: 10% by weight (isooctane is used as an indicator to estimate the non-selective volume that does not take part in this separation).

[0101] The adsorbent is a zeolite of the Y faujasite type substituted with sodium. The amount of sorbent used in these experiments was about 55 g.

[0102] The activations requ...

Embodiment 2

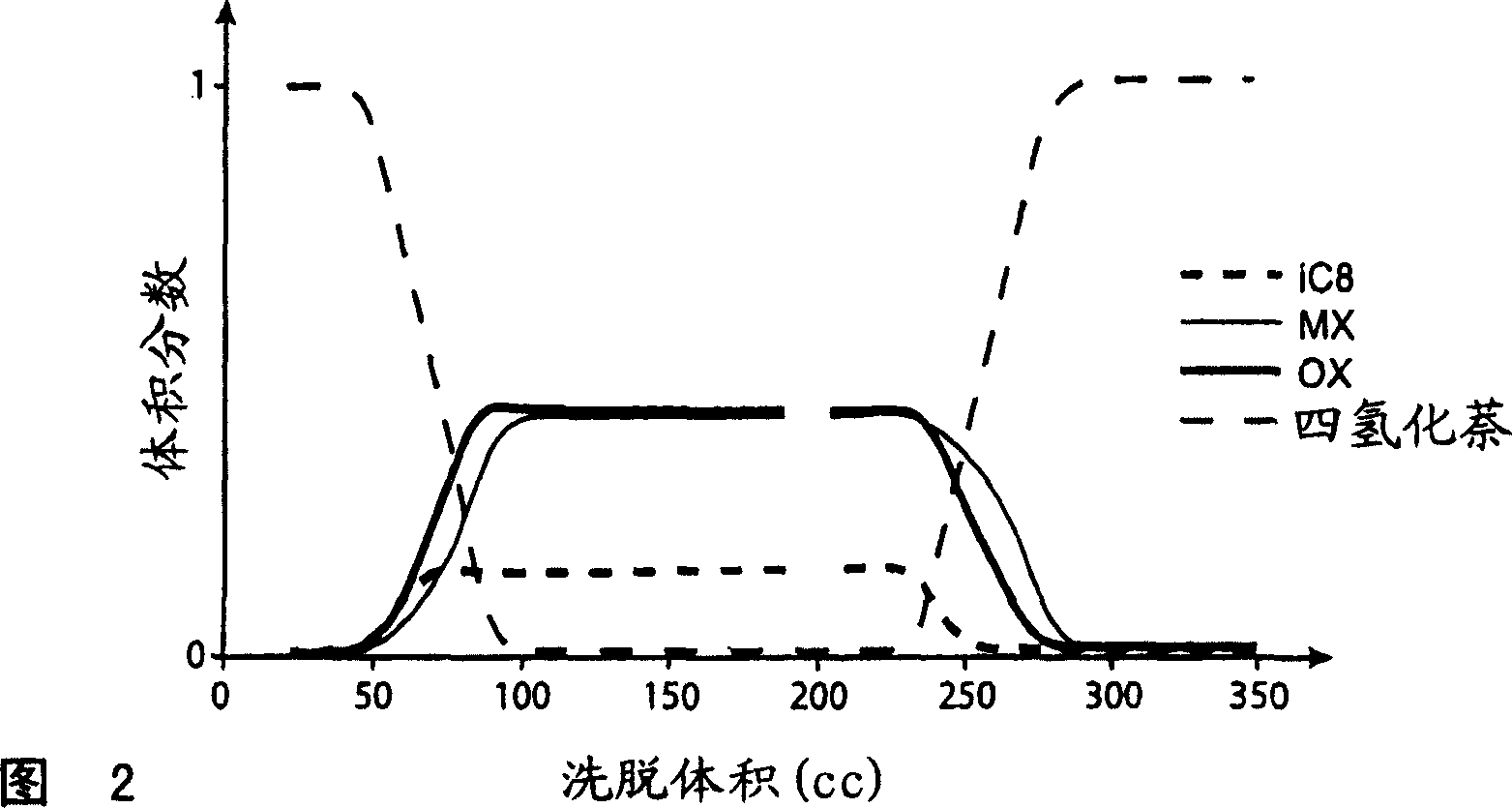

[0124] In this example, a breakthrough test (head chromatography) was performed to evaluate tetralin efficiency in the separation of meta-xylene from a meta-xylene / ortho-xylene mixture.

[0125] A sodium-substituted Y faujasite-type zeolite (expressed as NaY) is used as the adsorbent, and the loss on ignition at 500° C. is less than 0.05% by weight. The adsorption temperature (same as the desorption temperature) was fixed at 160°C.

[0126] The experiment used a sorbent volume of 56.6 g prior to activation.

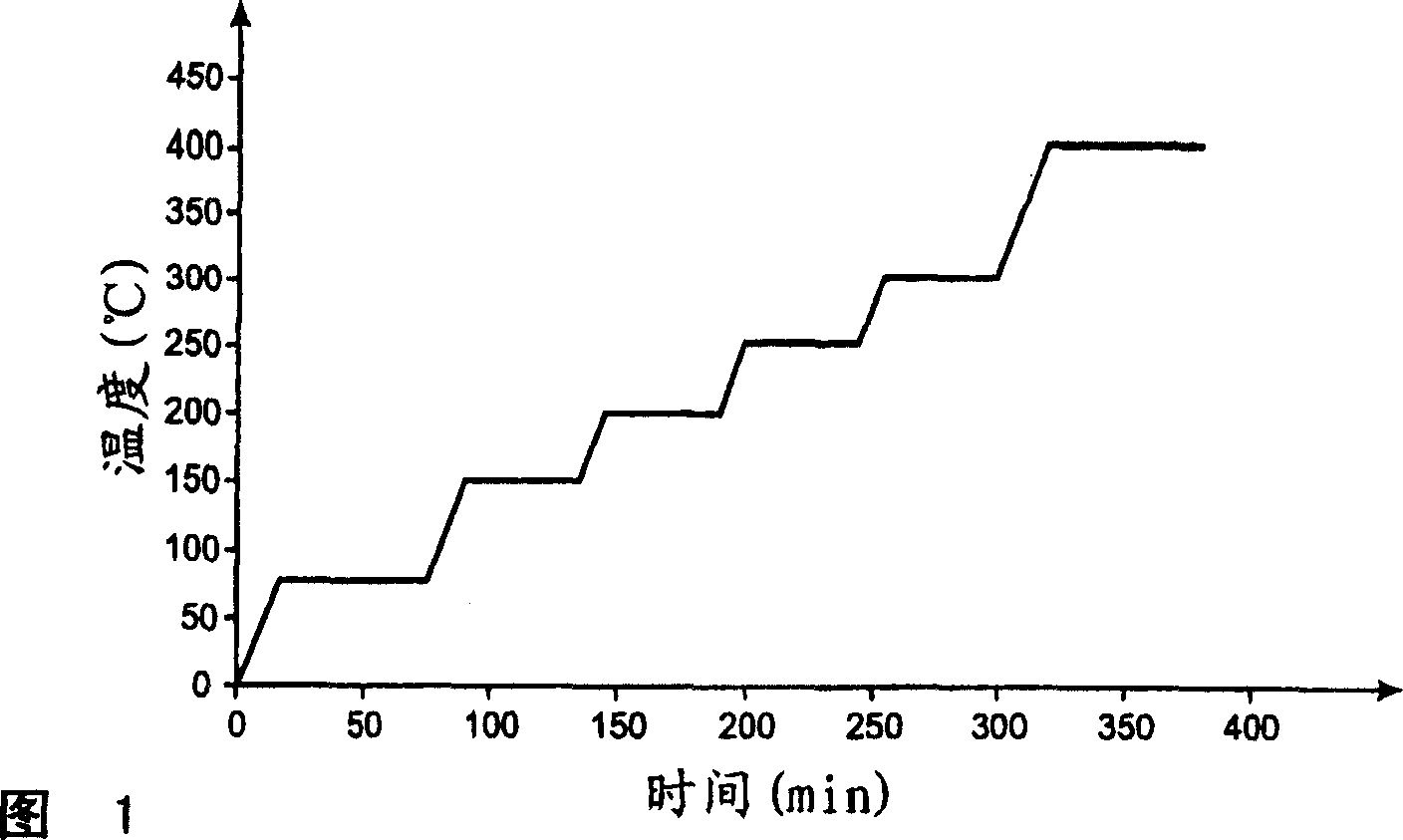

[0127] The adsorbent is then pretreated so that it is injected into the nitrogen column at room temperature with a flow rate of 40 l / h, and then the temperature is raised to 80 ° C, 150 ° C, 200 ° C, 250 ° C, 300 ° C and 400 ° C in stages, so that activation. Between these stages, the temperature was increased linearly with a ramp of 5°C / min.

[0128] The temperature of the other stages was maintained at 80°C and 400°C for 1 hour and 45 minutes, respectively. Figure 1...

Embodiment 3

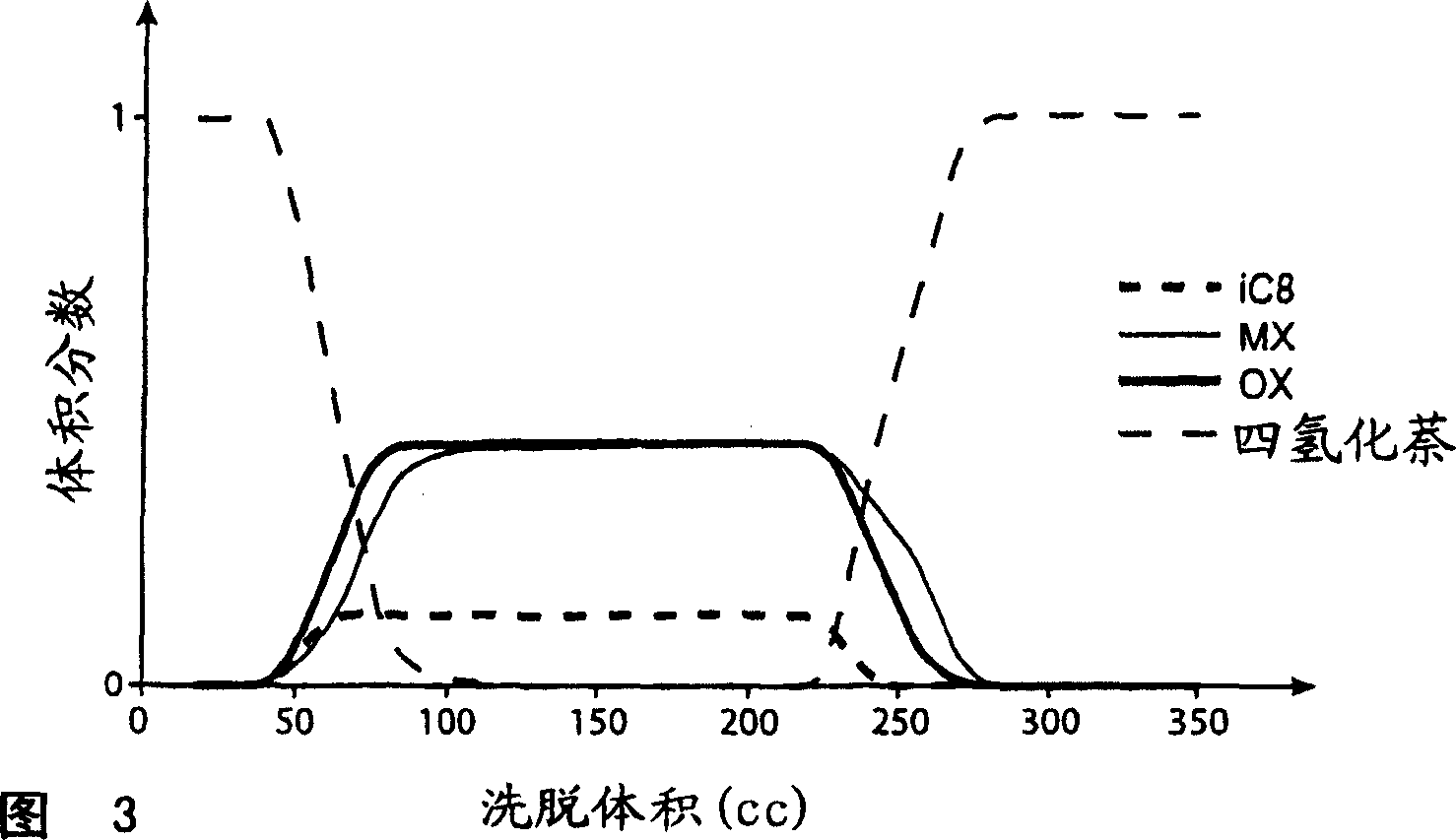

[0158] In this example, a breakthrough test (head chromatography) was performed to evaluate tetralin efficiency in the separation of meta-xylene from a meta-xylene / ortho-xylene mixture.

[0159] A sodium-substituted Y faujasite-type zeolite (represented by NaY) was used as an adsorbent, and the loss on ignition at 500° C. of this zeolite was 2.2% by weight. The adsorption temperature (same as the desorption temperature) was fixed at 140°C.

[0160] The experiment used a sorbent volume of 55.9 g prior to activation.

[0161] The activation required to achieve a loss on ignition of 2.2% at 500° C. was performed externally in a tube furnace using a nitrogen flow of 400 l / h.

[0162] The loss on ignition at 500°C is less than 0.05%.

[0163] The operating conditions for achieving the penetration test and releasing the penetration test include the following operations:

[0164] 1) Refill the column with adsorbent and place the column in place in the test strip;

[0165] 2) refi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption temperature | aaaaa | aaaaa |

| adsorption temperature | aaaaa | aaaaa |

| adsorption temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com