Hollow tray separator

A technology of splitting machine and empty pallet, which is applied in the direction of destacking, transportation and packaging of objects, which can solve problems such as affecting the efficiency of the assembly line and high labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

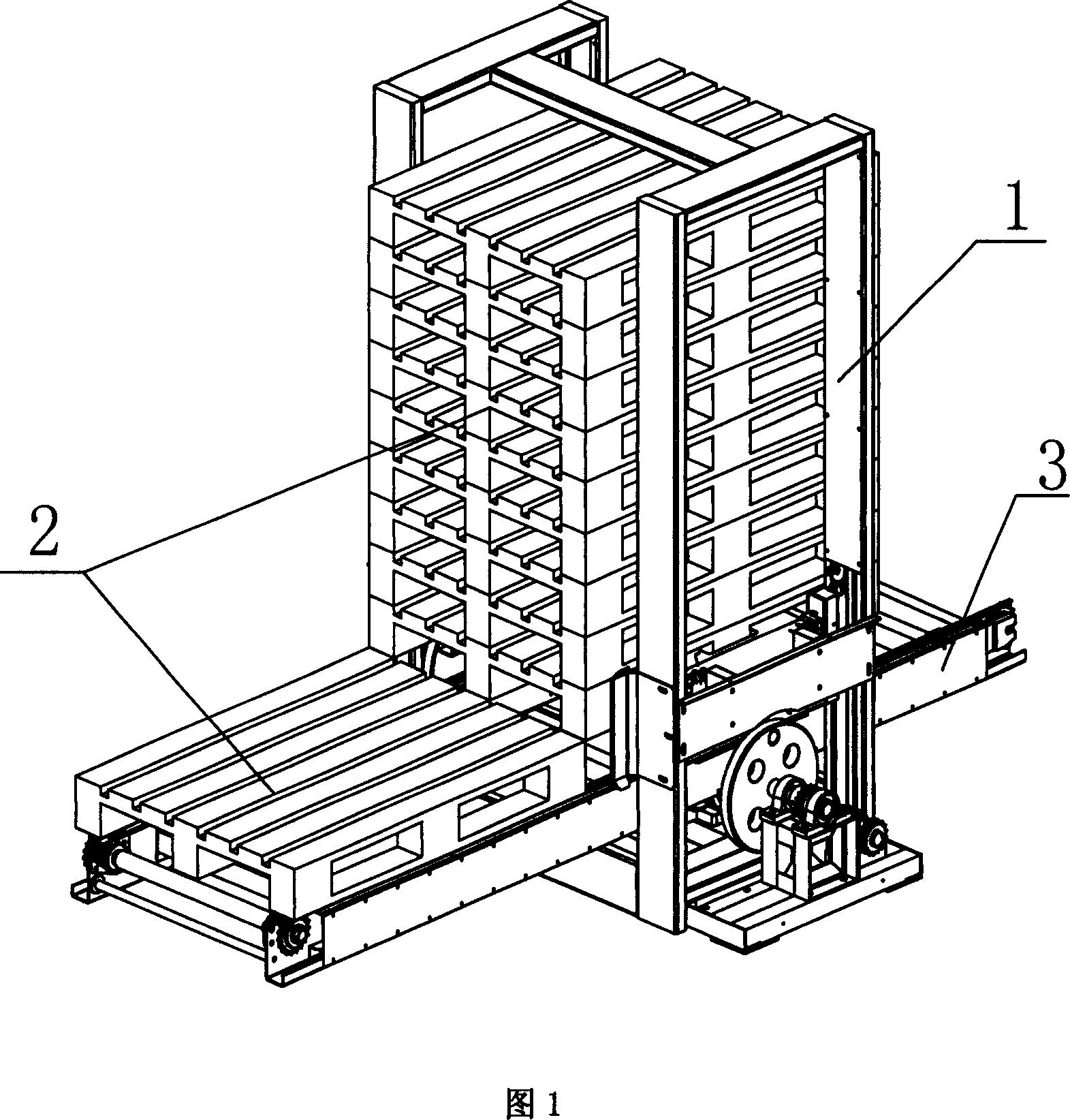

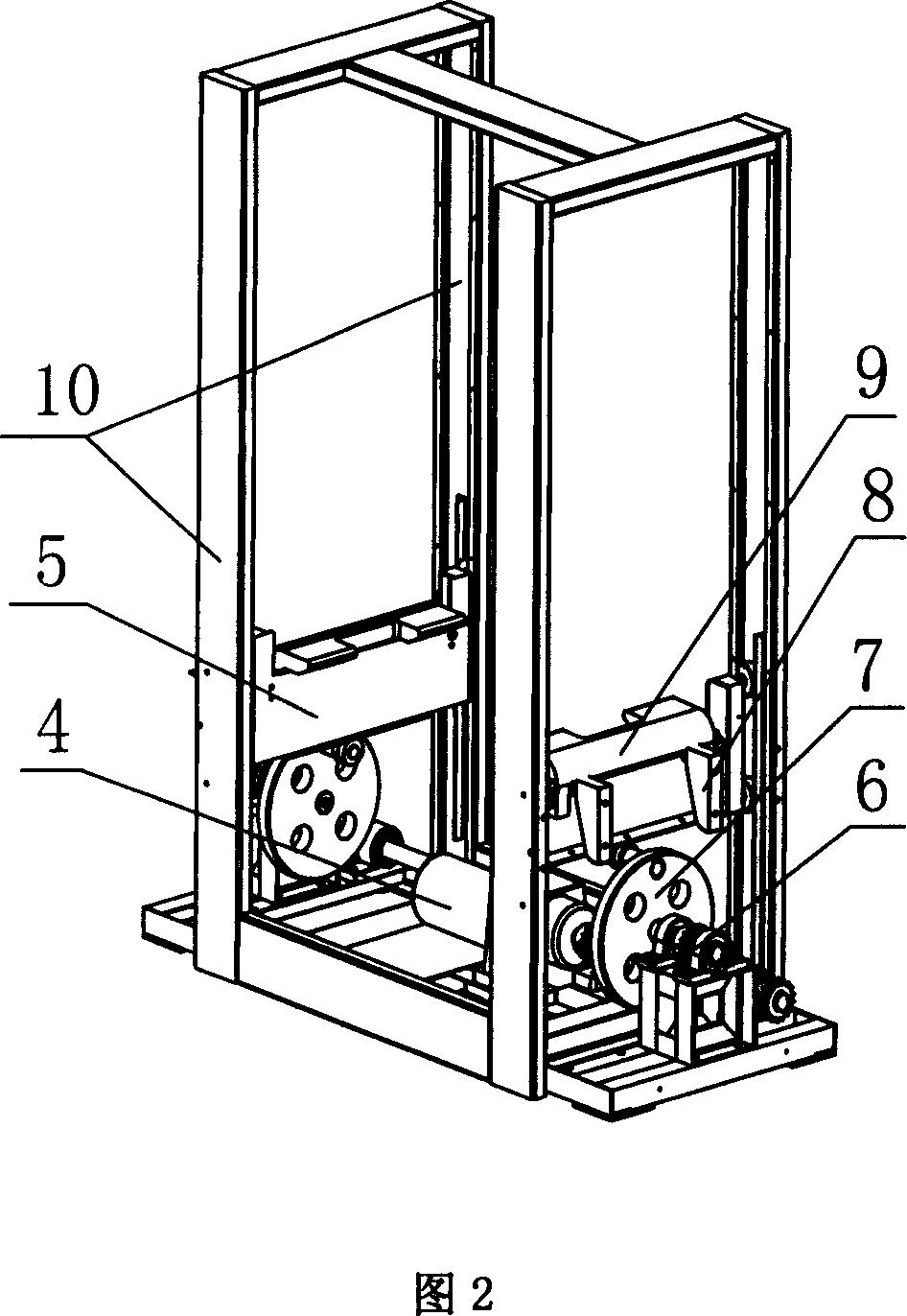

[0012] As shown in Figure 1 and Figure 2, the pallet stacking frame 1 includes a chassis and four columns, the conveyor belt 3 passes through the pallet stacking frame 1, and a guide rail perpendicular to the conveyor belt 3 is formed on each of the four columns 10. A trolley 5 is respectively provided between a pair of guide rails on the same side of the conveyor belt 3, and the two trolleys 5 can slide up and down on the column along the guide rail 10, and the bottoms of the two trolleys 5 are respectively seated on two eccentric wheels 7. Motor 4 is installed on the chassis of pallet stacking frame 1, and motor 4 drives two eccentric wheels 7 to rotate through transmission mechanism 6, and two tackles 5 can slide up and down synchronously when eccentric wheels 7 rotate.

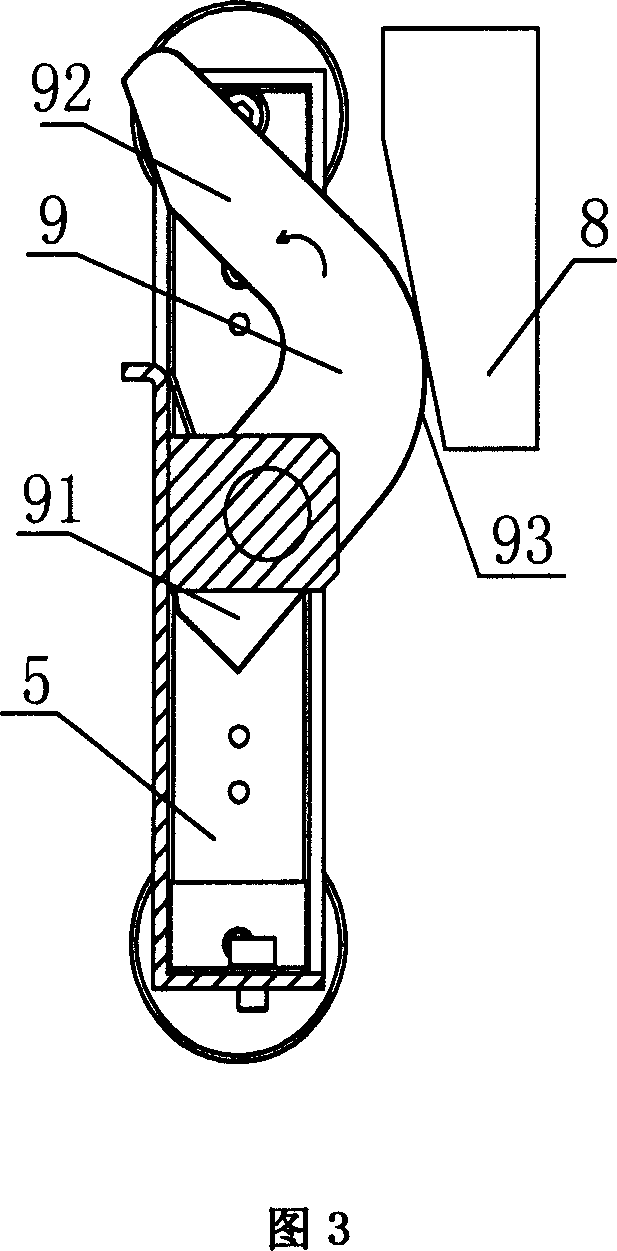

[0013] Pulley 5 is also provided with telescopic fork pliers 9, shown in Figure 3 is a kind of fork pliers that realize telescoping by turning over, it includes claws 92 and root 91 that are at right angles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com