Steel lconcrete prefabricated plate with rib

A technology of reinforced concrete and prefabricated slabs, applied to floors, building components, buildings, etc., can solve the problems of difficult construction period, high cost, and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

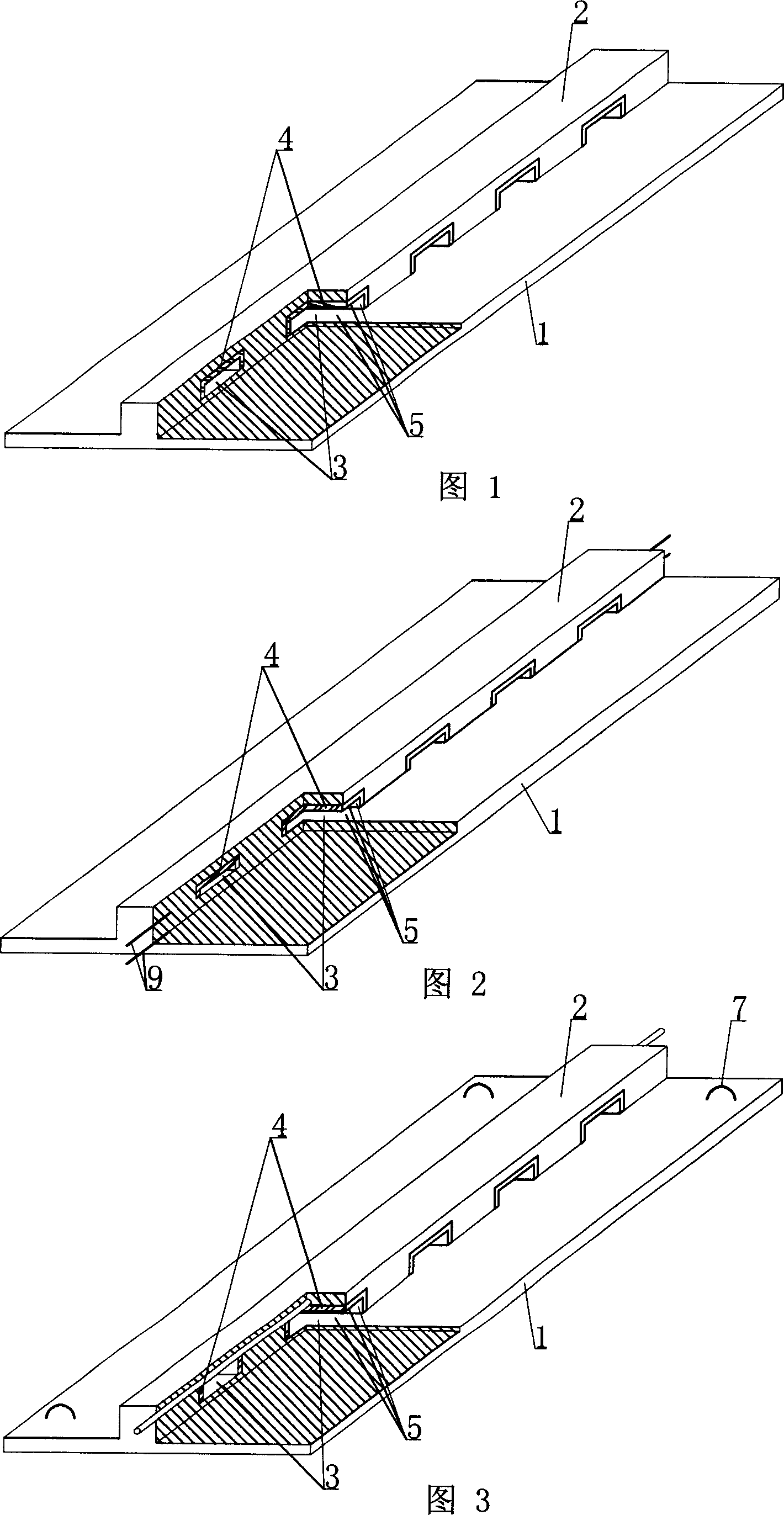

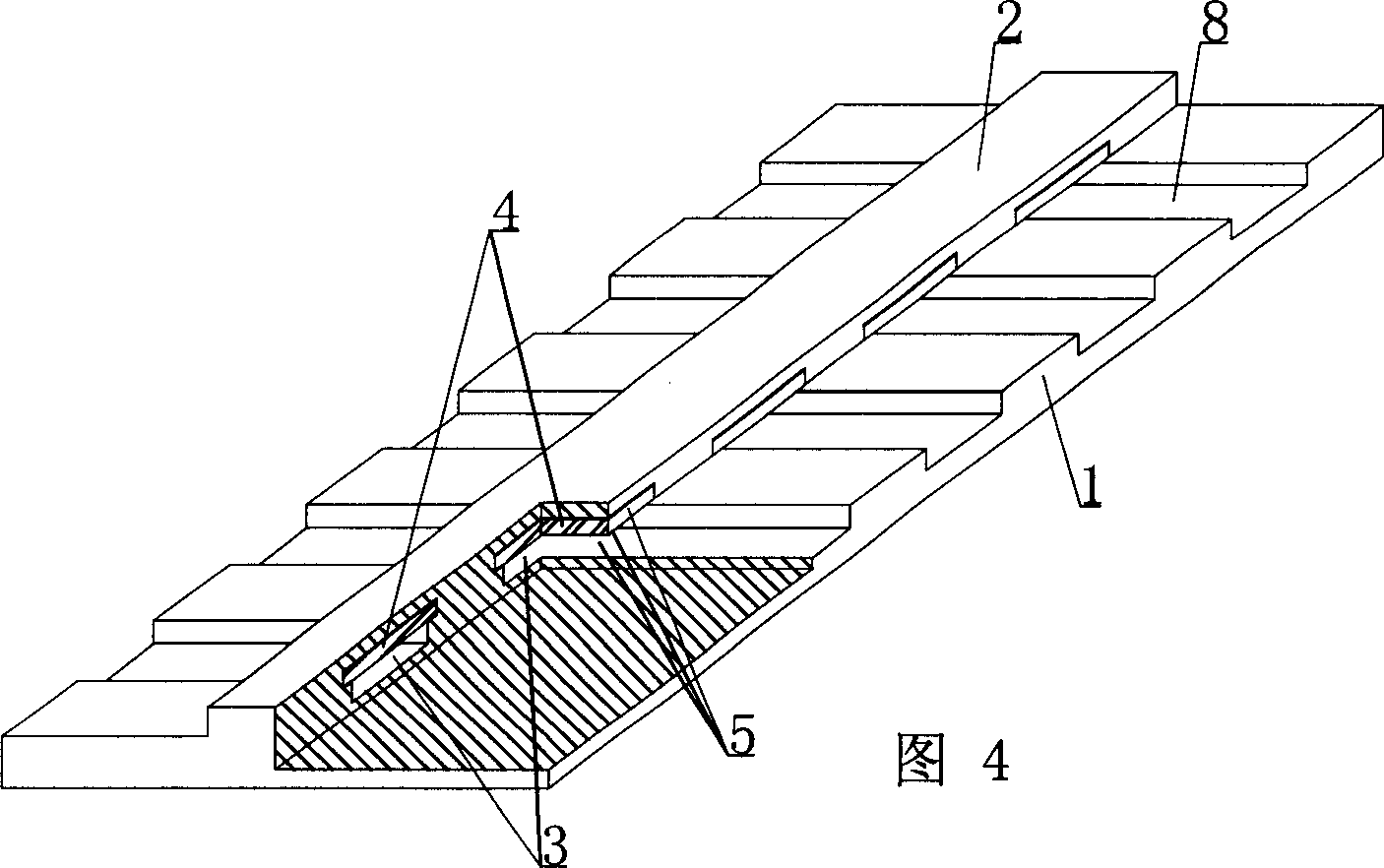

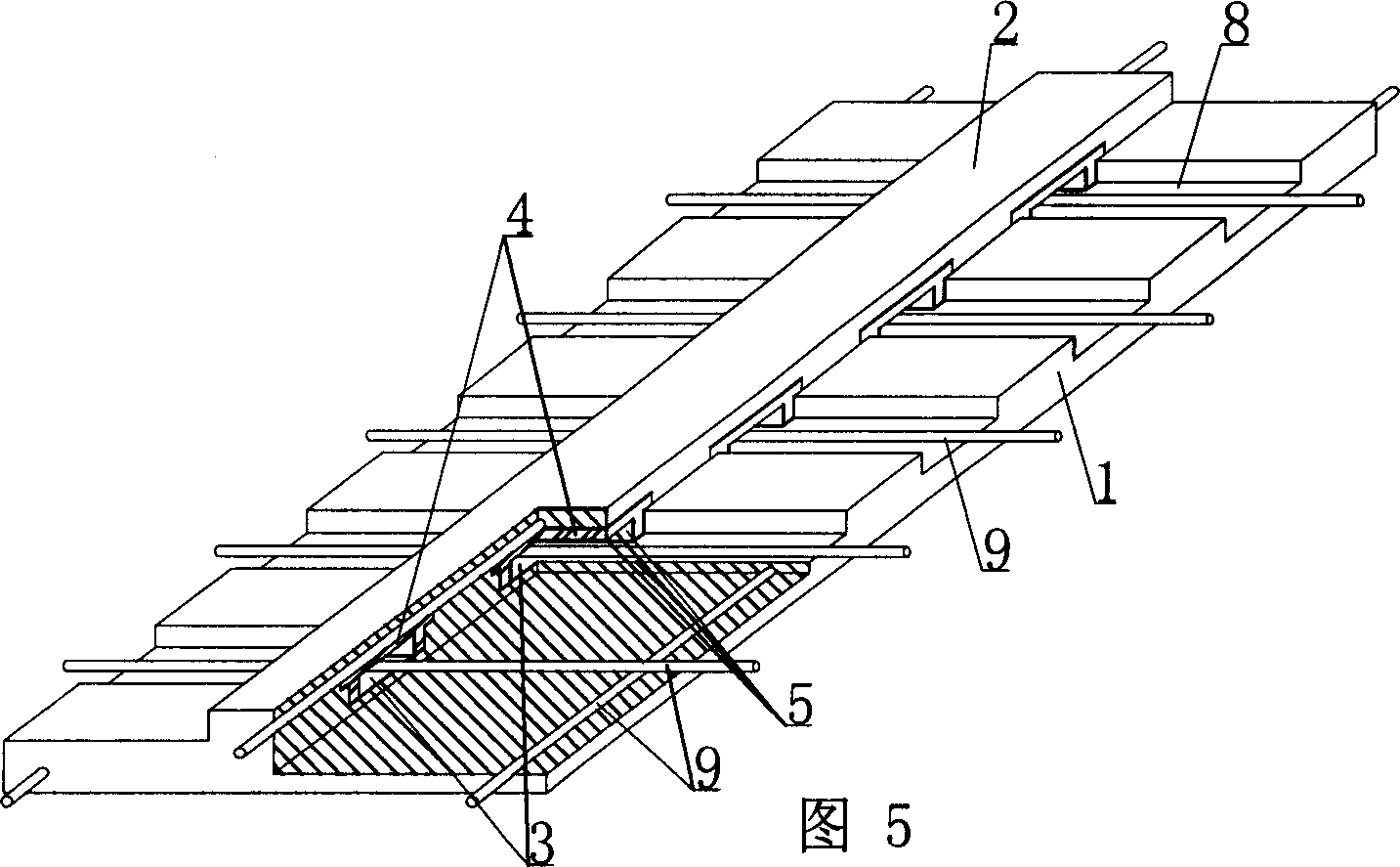

[0069] As shown in the accompanying drawings, the present invention includes a reinforced concrete bottom plate 1 and a reinforced concrete longitudinal rib 2, and is characterized in that there is a hole 3 transversely penetrating the longitudinal rib 2 or / and the bottom plate 1, and the hole 3 part has a non-drawing hole forming hole mold The hole wall 5 of 4, part of the hole wall 5 is a core-pulling wall that is drawn to form a hole. In each accompanying drawing, 1 is a base plate, 2 is a longitudinal rib, 3 is a hole, 4 is a hole mold, and 5 is a hole wall. In the following accompanying drawings, those with the same number have the same description. As shown in Figure 1, the reinforced concrete ribbed prefabricated slab includes a reinforced concrete bottom plate 1 and a reinforced concrete longitudinal rib 2, which has a hole 3 that runs through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com