Circulation fixing bed split phase combustion technology

A combustion method and fixed bed technology, which is applied in the field of fixed bed coal-fired boilers, can solve problems such as difficult desulfurization and manufacturing difficulties, and achieve the effects of reducing desulfurization costs, improving ventilation, and improving desulfurization effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

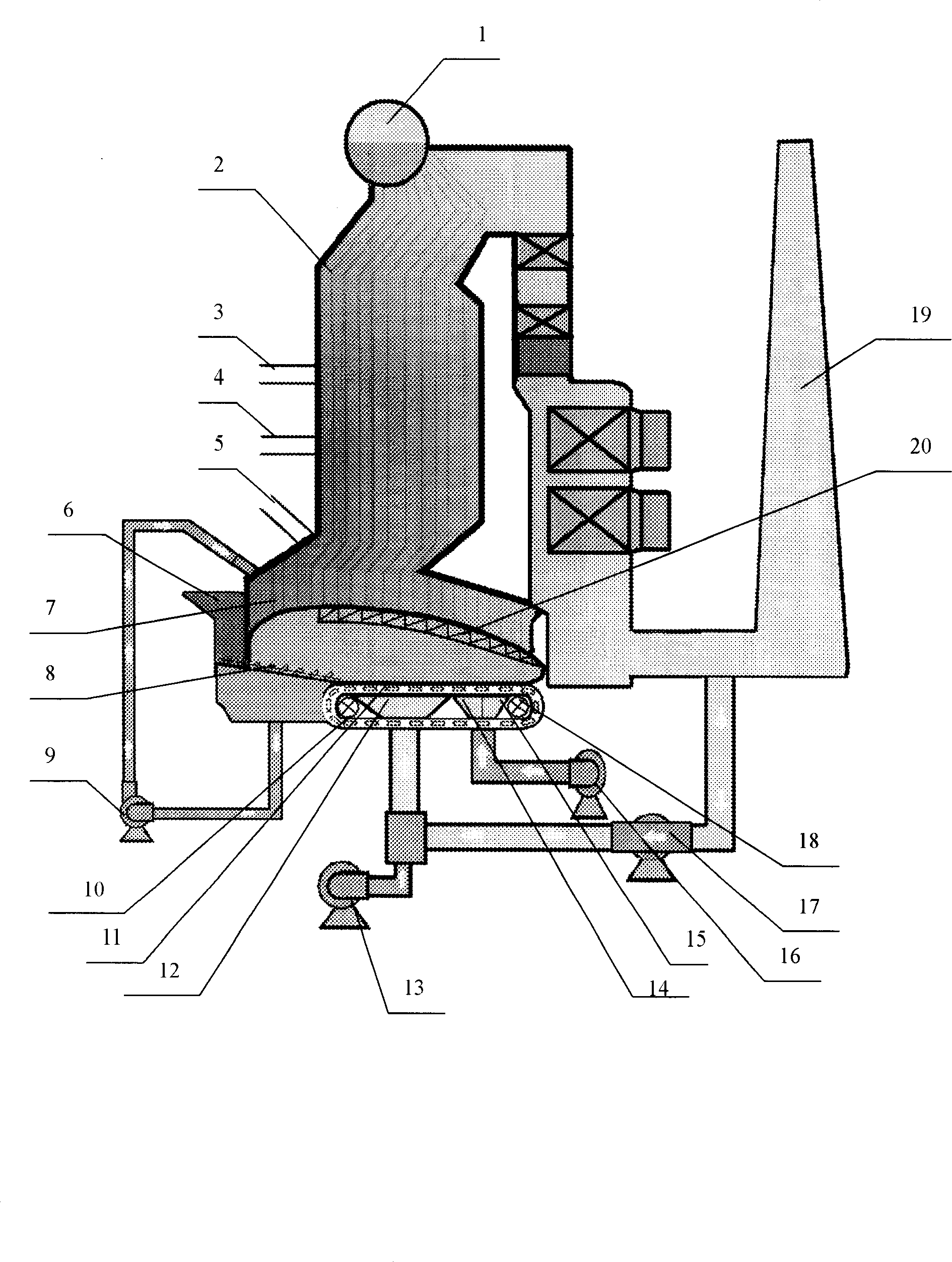

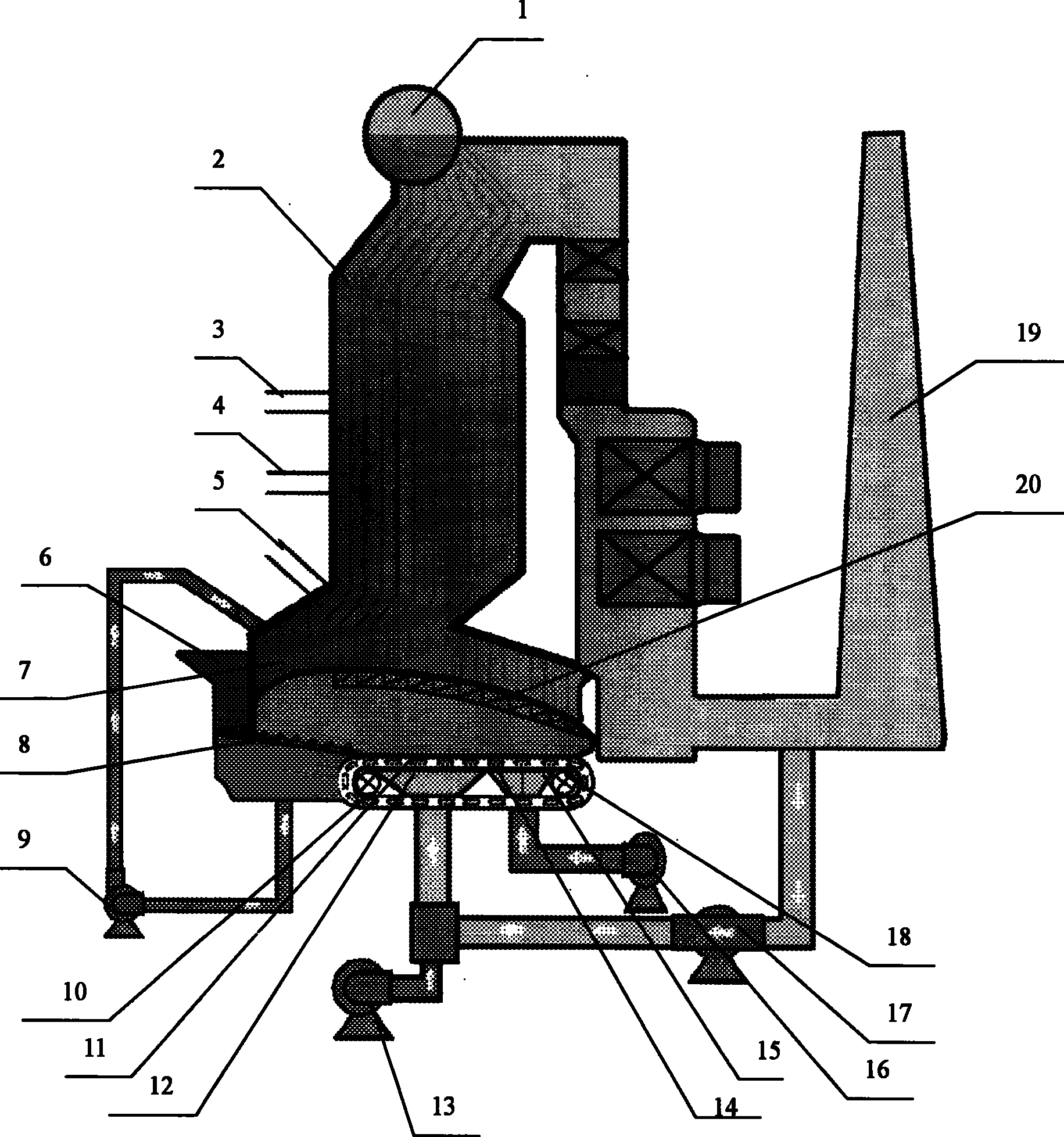

[0030] Specific embodiments: the fuel of the technology of the present invention is to use wet coal particles, the raw coal is made into wet coal particles with a diameter of 15 to 50 mm and put into the furnace, and the coal particles enter the preheating zone composed of reciprocating fire grates.

[0031] The present invention is designed as a double grate boiler, the front part is a reciprocating grate 8, and the rear part is a chain grate 11; Blast, mixed with return flue gas to control the temperature of the coal seam; the burnt slag is cooled to 200°C by cold air and discharged.

[0032] Through the gas combustion zone 7 at the upper end of the upper arch 20, the flue gas, combustible gas, and hot air after the tail heating are gas-phase combusted, which is also the secondary combustion of the flue gas. The flue gas after the secondary combustion is burned three times and four times. Exhaust the wind to support the combustion, and the combustible gas is completely burne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com