Pump structure

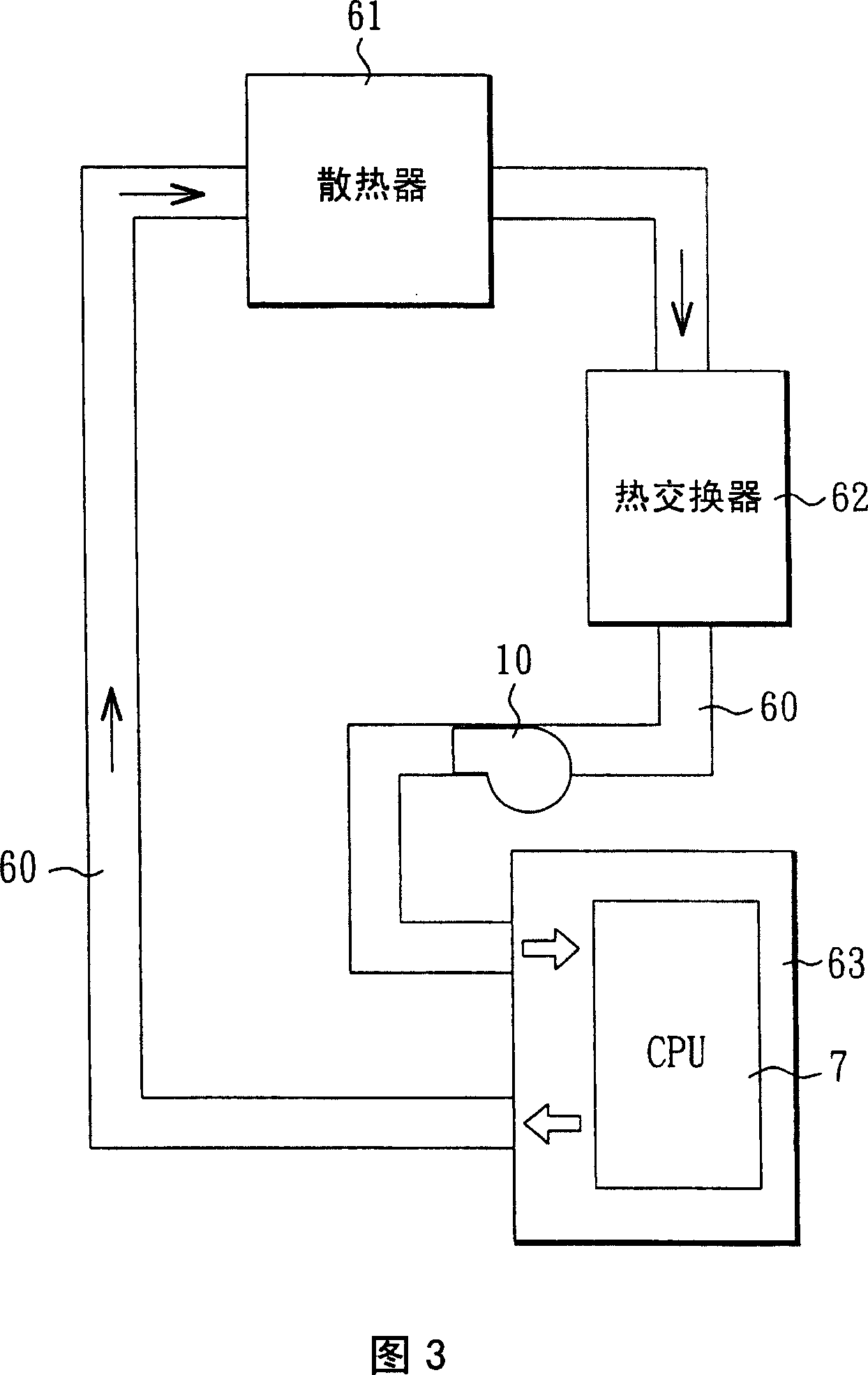

A motor and central technology, which is applied in the field of drive pump structure, can solve the problems such as the inability to improve the liquid cooling effect, the limitation of the maximum water output, and the fixed water output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

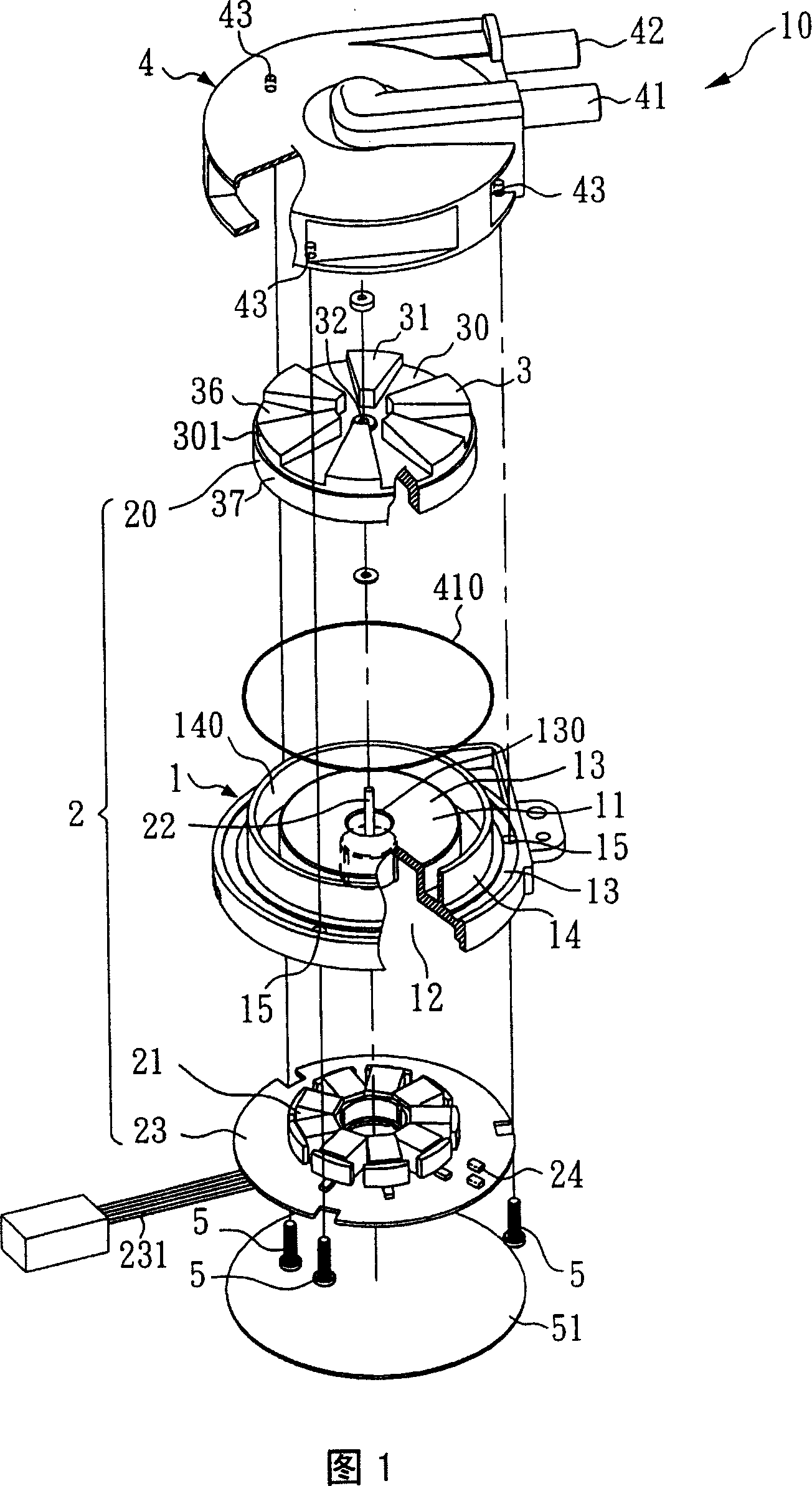

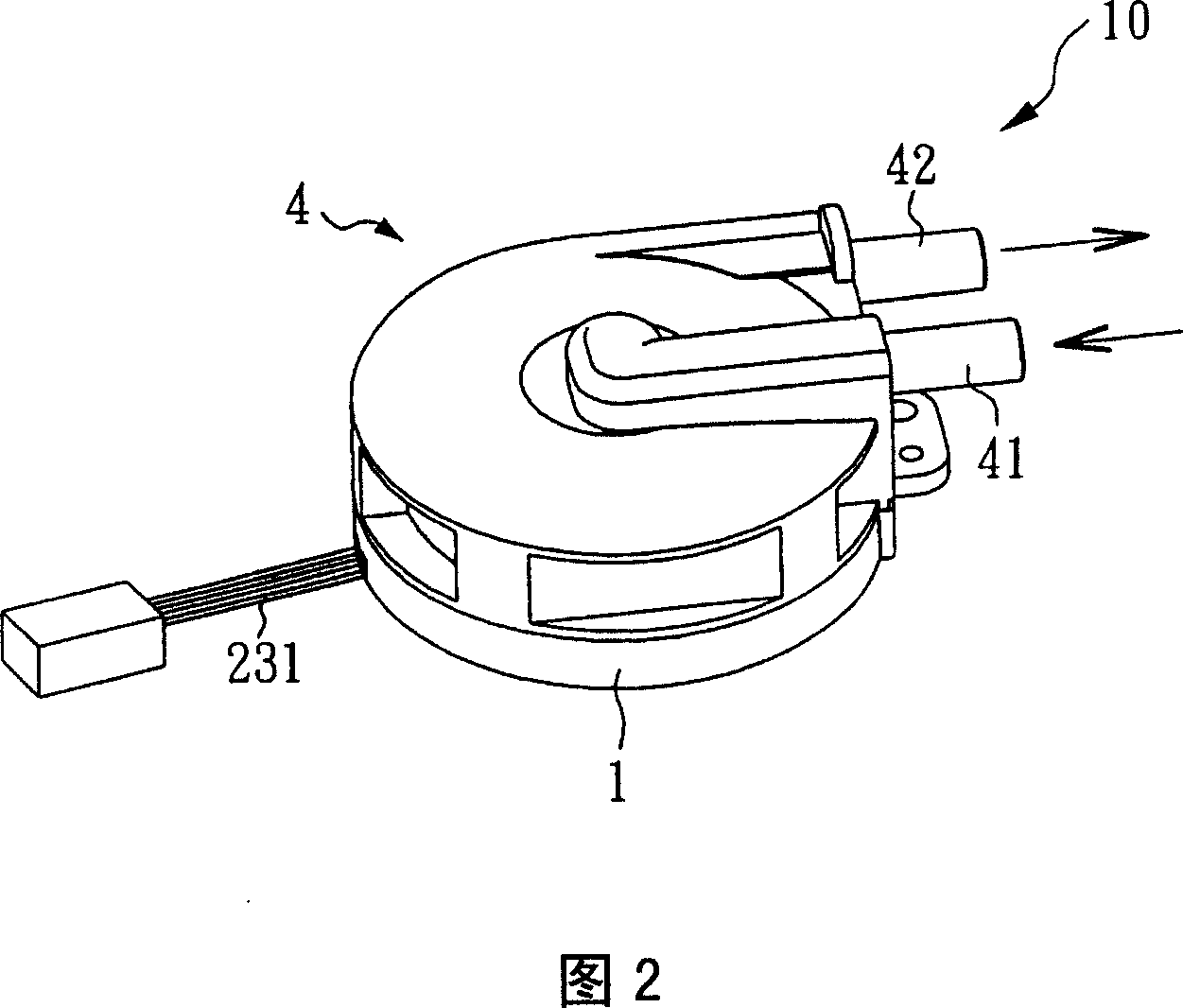

[0024] Please refer to FIG. 1, which is an exploded view of a preferred embodiment of the present invention. As shown in the figure, a pump structure 10 includes a base 1, a motor 2, a central pivot 22, a pump blade 3, and a Upper cover 4.

[0025] In this embodiment, the base 1 protrudes upwards with a convex portion 11, and the convex portion 11 includes an upper surface 13, a lower groove 12, and a central opening 130, wherein the central opening 130 communicates with the upper surface 13 and Lower groove 12.

[0026] In addition, an annular wall 14 protrudes from the upper surface 13 of the base 1, and an oil seal 410 is sheathed on the annular wall 14. In this embodiment, the oil seal 410 uses an O-ring. At the same time, the annular wall 14 and the The protrusions 11 are spaced apart from each other and form an accommodating chamber 140 .

[0027] The motor 2 in the accompanying drawing is a DC brushless three-wire servo motor 2 using 5VDC, including a rotor 20, a stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com