Double-helix flow diverter

A technology of conducting fluid and double helix, applied in the field of double helix conducting fluid, can solve the problems of reduced water flow energy, large hydraulic loss, low pump efficiency, etc., and achieve the effect of reducing hydraulic loss, improving hydraulic efficiency and expanding cross-sectional area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

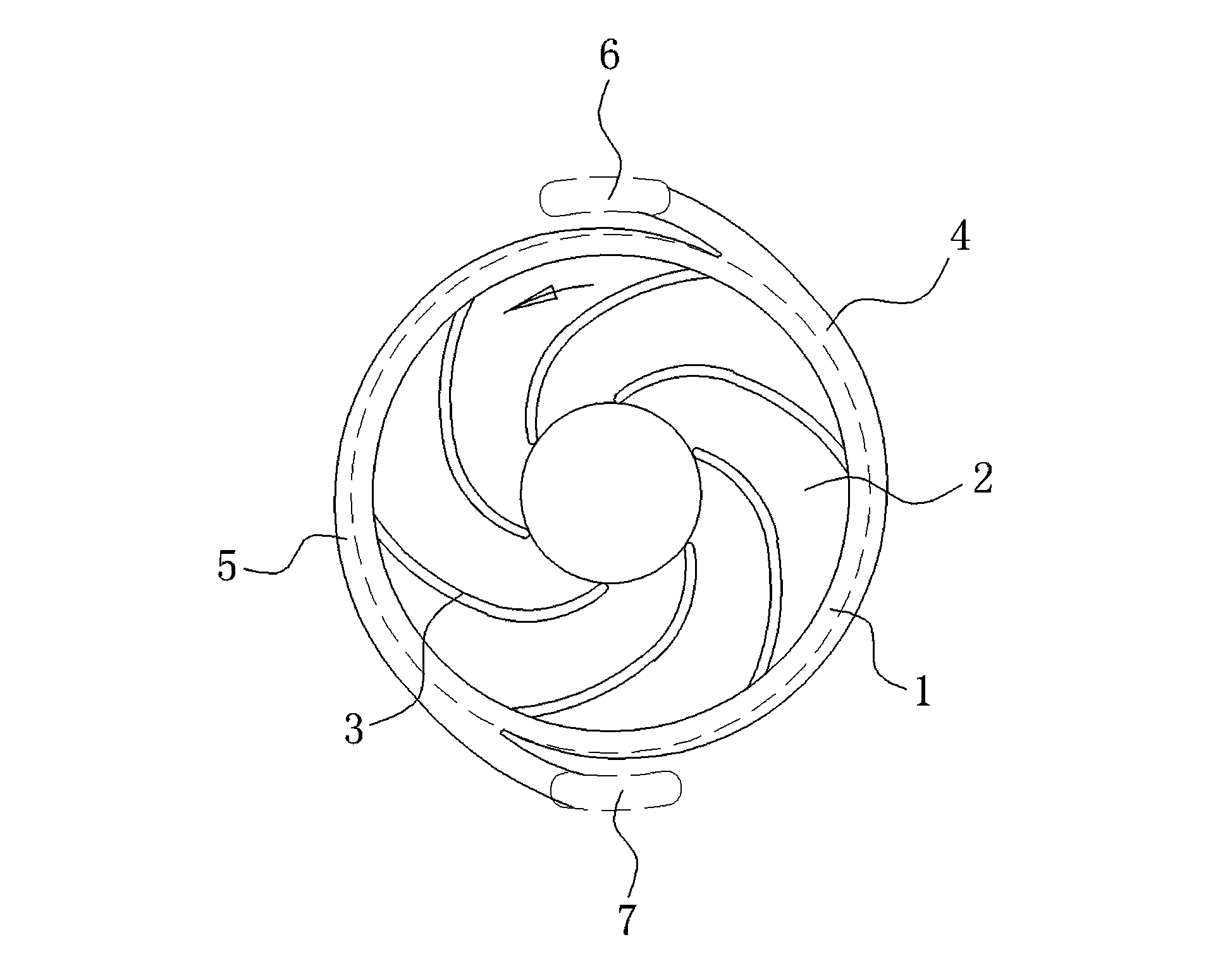

[0015] Such as figure 1 As shown, the double helix guide body includes a main body 1, and the impeller 2 of the centrifugal pump is arranged in the main body 1, and a plurality of blades 3 are evenly distributed on the impeller 2. Such as figure 1 As shown, the edge of the body 1 is provided with two spiral flow passages communicating with the body 1: the first spiral flow passage 4 and the second spiral flow passage 5, and the water inlet end of the first spiral flow passage 4 is tangent to the main body 1 Set, the water inlet end of the snail-shaped flow channel two 5 is arranged tangentially with the body 1, the outer end of the snail-shaped flow channel one 4 has a water outlet one 6, and the outer end of the snail-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com