Distribution method of implementing remote weighing transporting

A long-distance, pneumatic conveying pipeline technology, applied in the direction of conveying bulk materials, conveyors, transportation and packaging, etc., can solve the problems affecting the accuracy of material proportioning, high equipment maintenance and maintenance costs, and high installation space requirements, and achieve equipment maintenance. And low maintenance cost, solve the effect of equipment installation and layout, stable and reliable transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

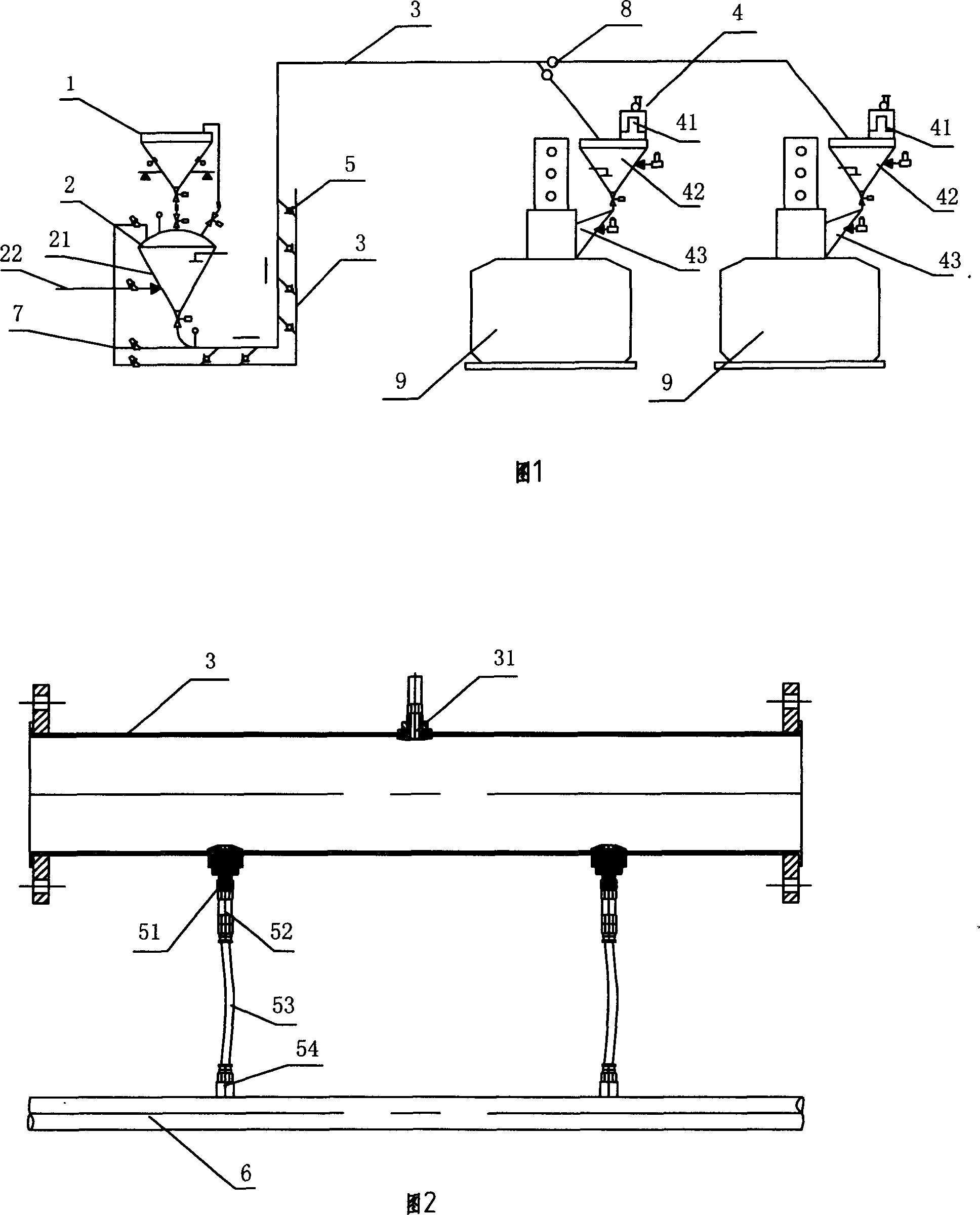

[0032] Embodiment 1, as shown in Figures 1 to 2, in the batching method for realizing remote weighing and conveying, the material sending device 2 is arranged and connected below the weighing and proportioning device 1, and is arranged on the wall of its tank body 21 There is an inlet pipe 22 for introducing pressurized gas and a pressure sensor, so that the material and air are fully mixed and pressurized.

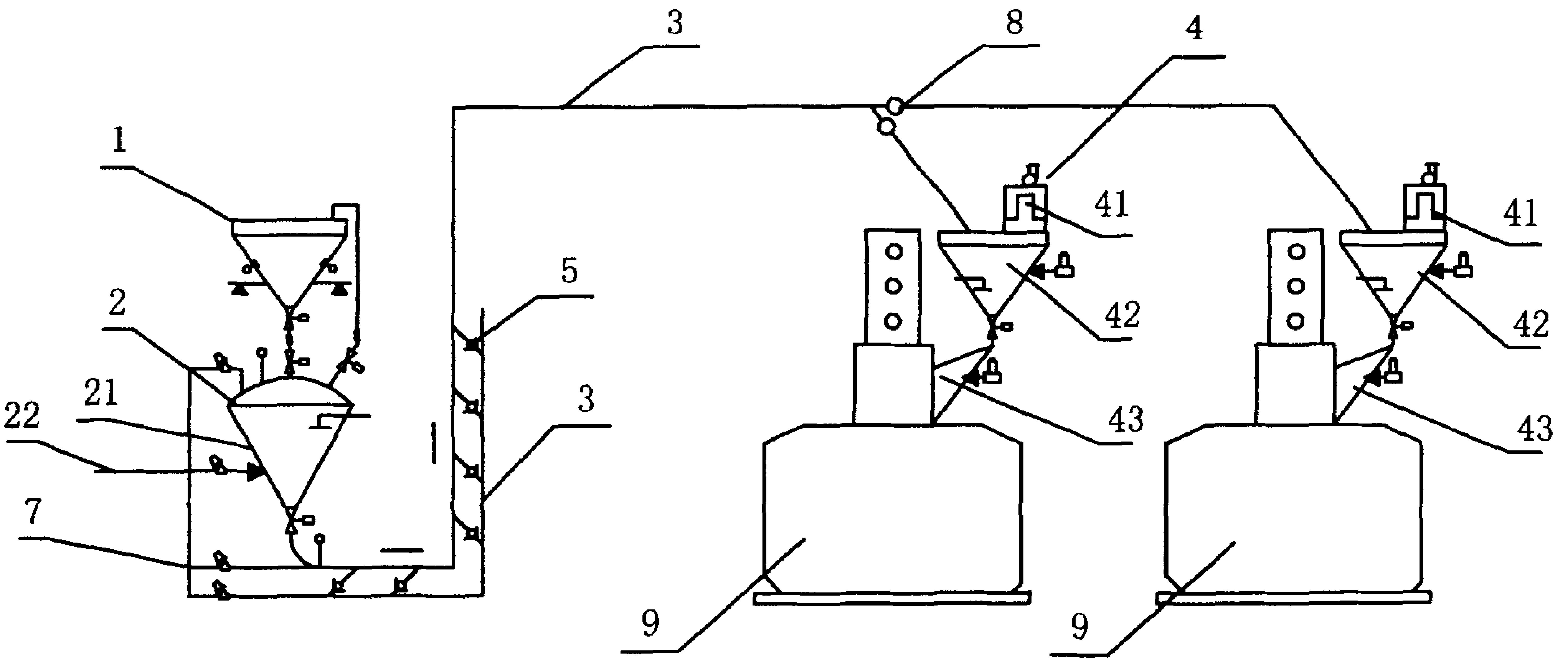

[0033] The pneumatic conveying pipe 3 communicates with the material sending device 2, and adopts a rubber braided pipe, and several pressure sensors 31 are arranged on its inner wall.

[0034] A sending control pipeline 7 is set between the material sending device 2 and the pneumatic conveying pipeline 3, which includes a pneumatic shut-off valve, a pressure regulating valve, a filter and the like.

[0035] The material receiving and feeding device 4 communicates with the pneumatic conveying pipeline 3 and the banburying equipment 9 , and includes a bag filter 41 , a mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com