Door and window lintel for motor vehicle

A technology for motor vehicles, motor vehicles, applied in the direction of vehicle components, engine seals, doors, etc., can solve the problems of increasing complexity and cost, expected cost and complexity increase, etc., to achieve the effect of reducing the possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

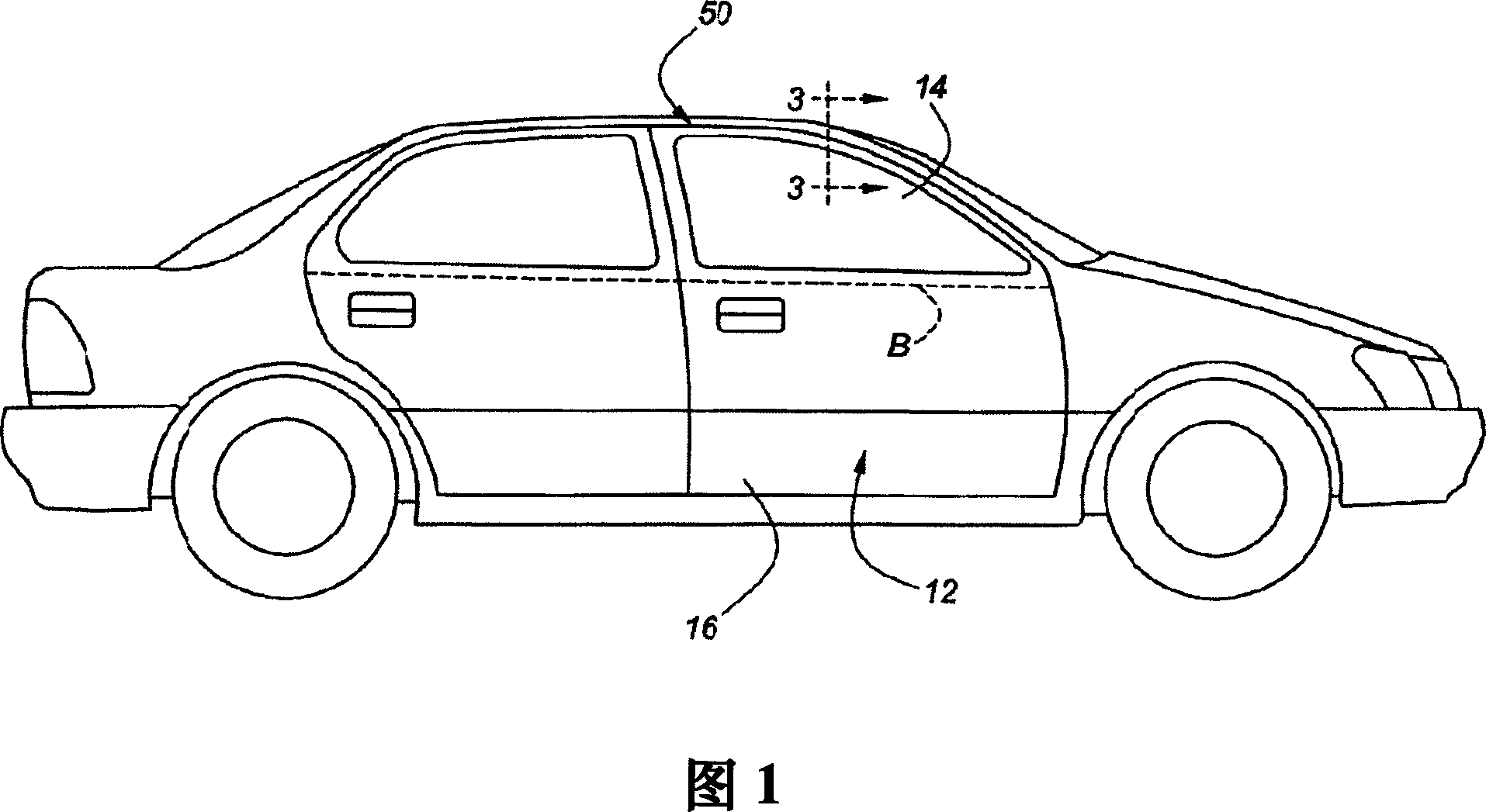

[0011] As shown in FIG. 1, a vehicle 10 has a door 12 with a glass window 14 mounted therein. The door 12 includes an outer panel 16 and a lintel 50 . In Figure 1, the term "sash" refers essentially to the portion 24 of the door 12 above the dotted line (labeled "B").

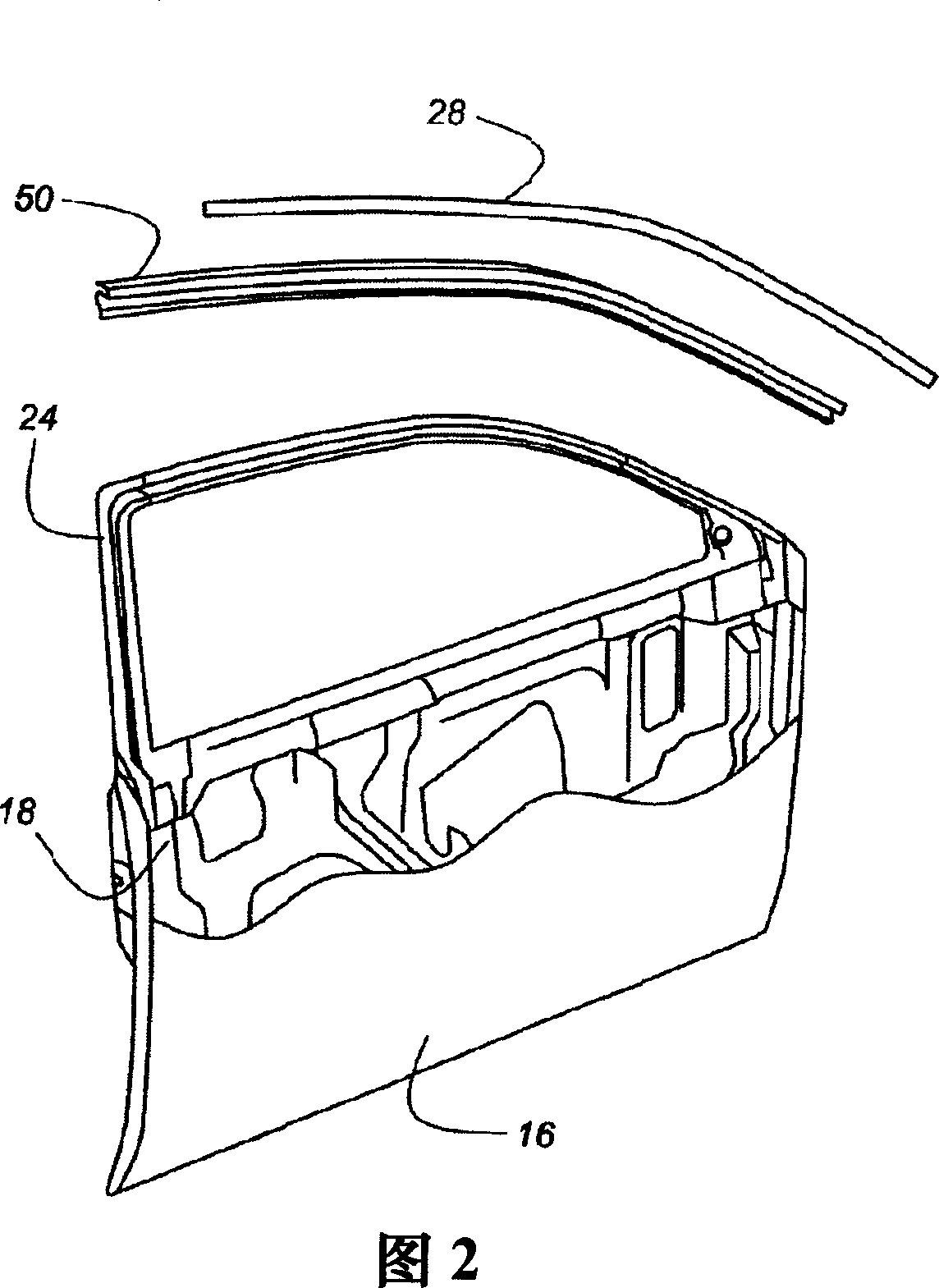

[0012] FIG. 2 shows a vehicle door 12 having an outer panel 16 covering an inner panel 18 . The window frame 24 is an integral part of the inner door panel 18 and can be welded together with the panel surface 18 or integrally formed with the panel surface 18 . The lintel 50 is shown in its exploded position, while it is shown assembled in FIG. 3 . Finally, the exterior trim molding 28 is shown in Figure 2, also in an exploded position.

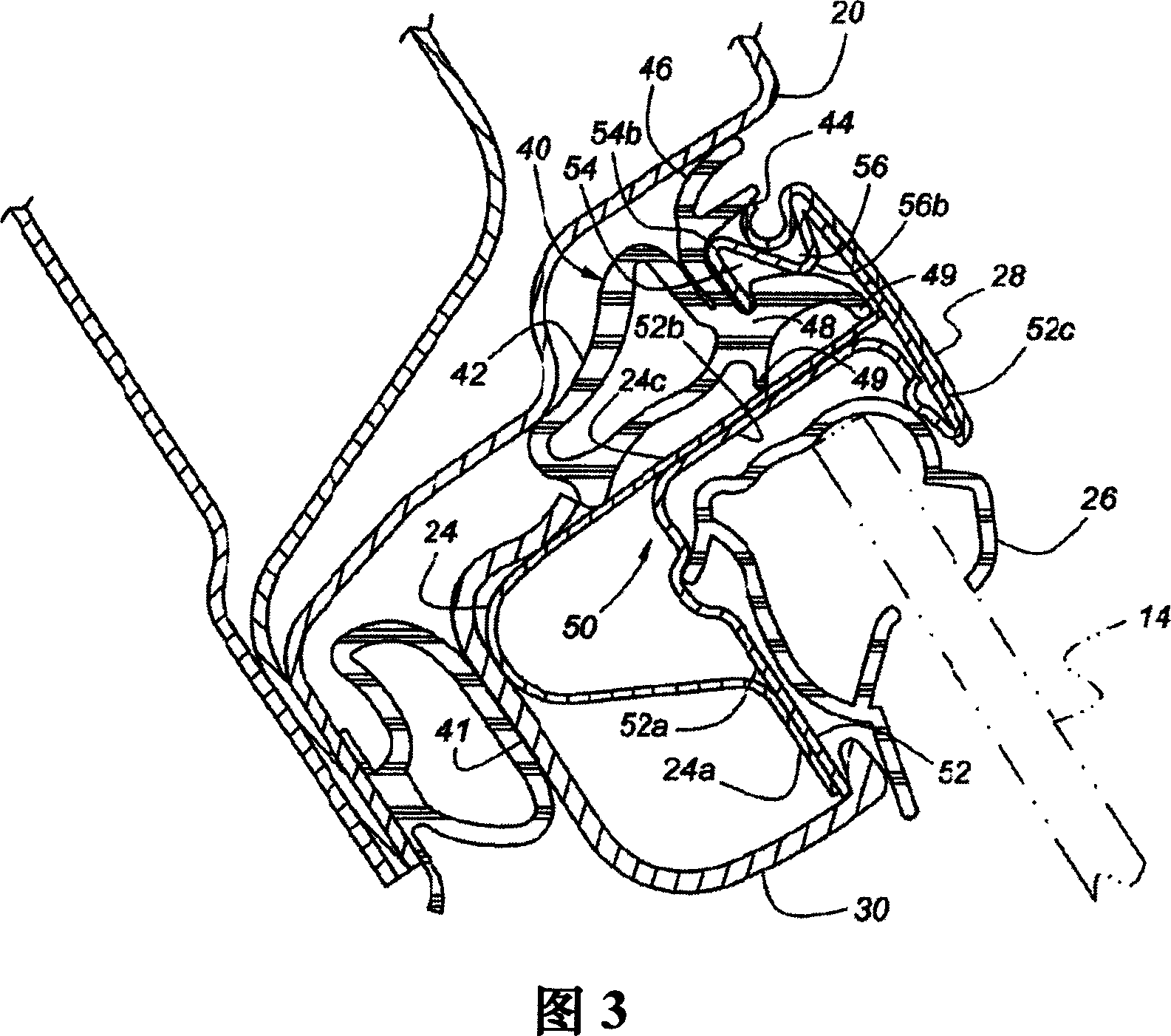

[0013] Turning now to FIG. 3 , which shows the glazing 14 mounted in the glazing strip 26, the glazing strip 26 is mounted in the lintel 50 and held thereto by means of the glazing strip holder 52, which Is the first integral part of the lintel. The glass sealing strip hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com