Dishware cleaning machine

A dishwashing machine and washing tank technology, applied in dishwashing machine/washing machine, dishwashing machine/rinsing-washing machine parts, dishwasher application, etc., can solve the problems of rising air humidity and user discomfort, etc. , to achieve the effect of good energy saving performance and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

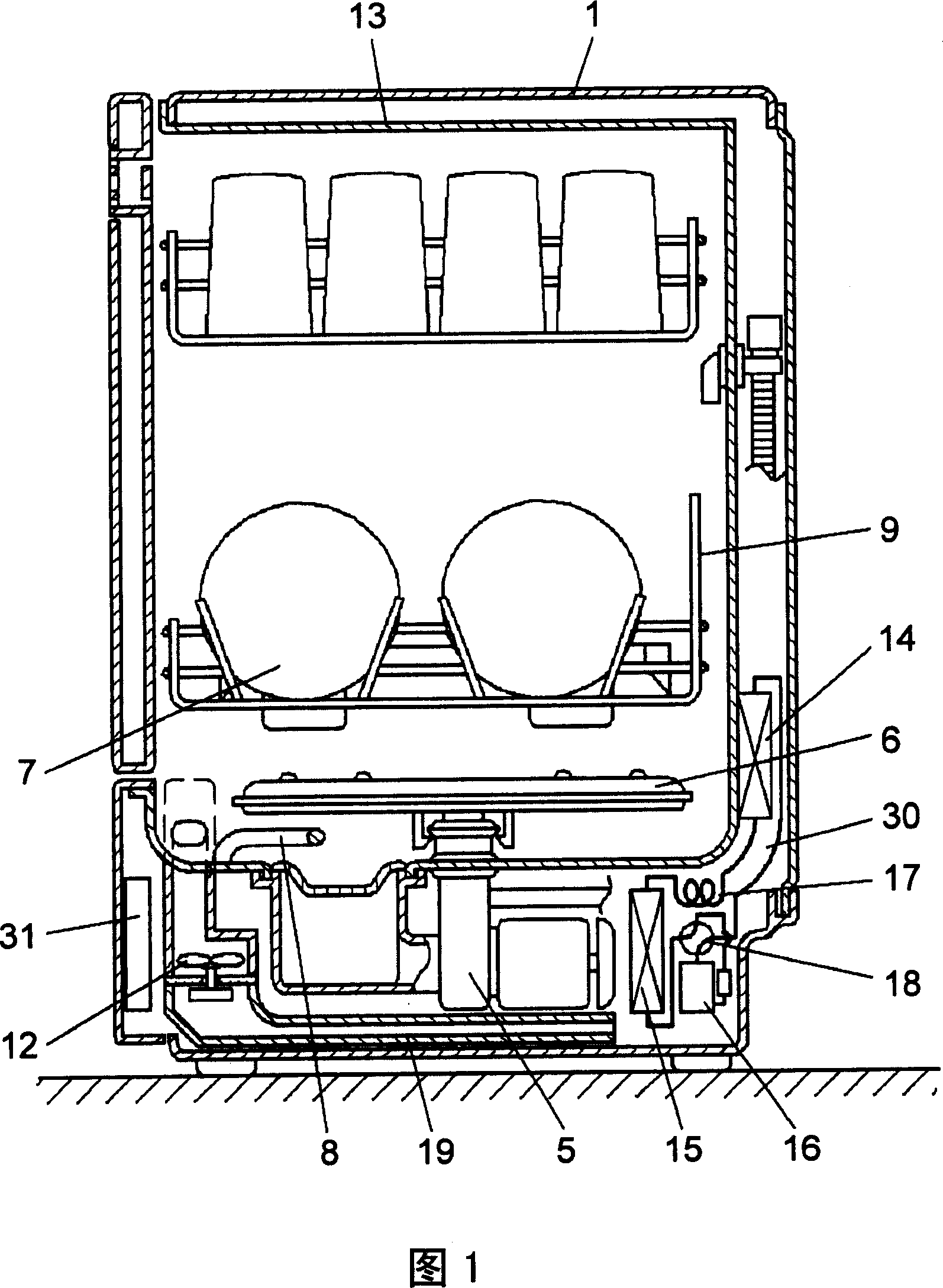

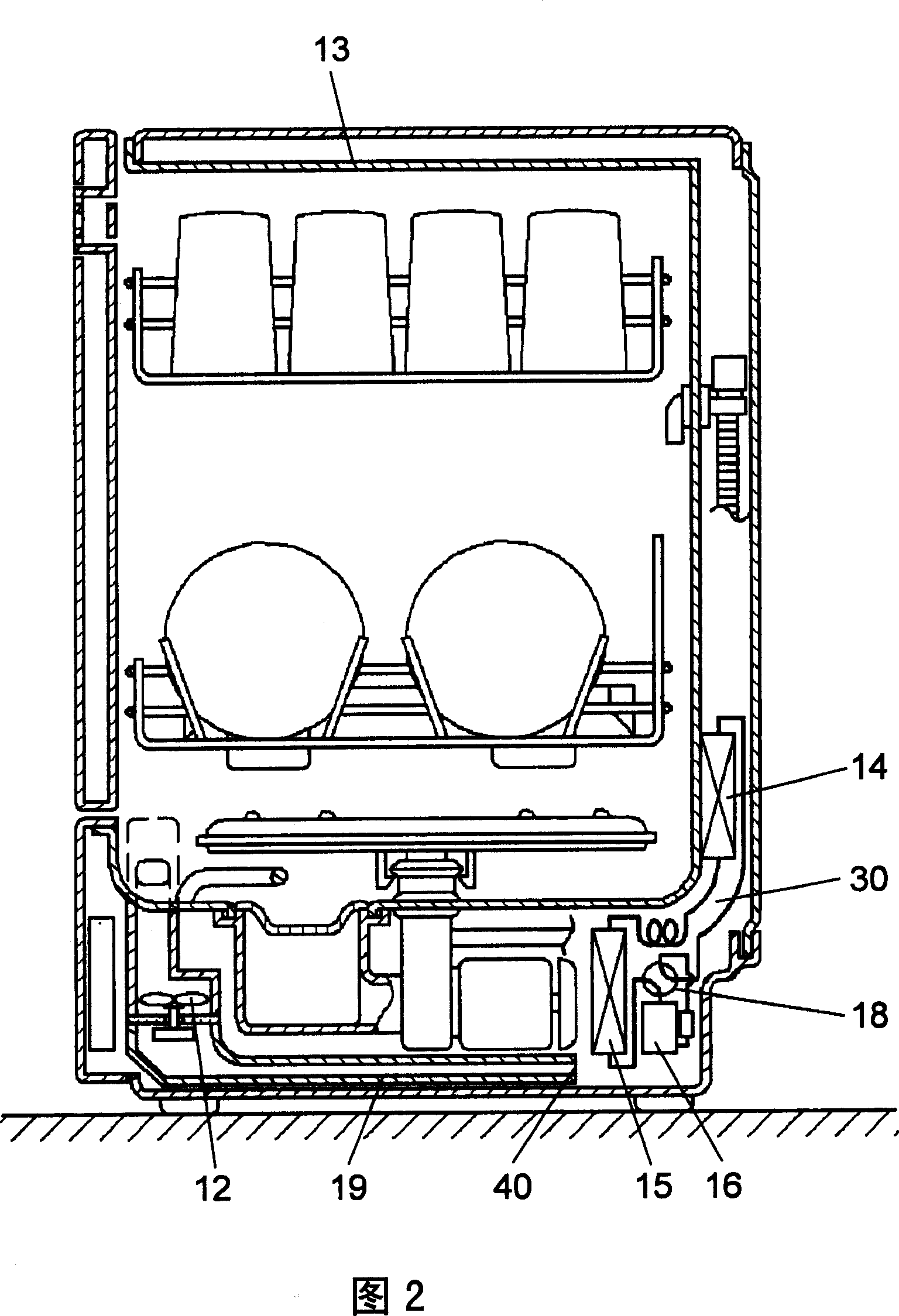

[0019] Fig. 1 is a side sectional view of the dishwasher in embodiment 1 of the present invention in the cleaning process, and Fig. 2 is a side sectional view of the dishwasher in the drying process.

[0020] First, the main components of the dishwasher in Embodiment 1 will be described using FIGS. 1 and 2 . The dishwashing machine of the present embodiment 1 includes: a cleaning tank 13; a heat pump unit 30; a control unit 31 for sequentially controlling a series of operation strokes such as cleaning, rinsing, heating and rinsing, and drying; The heat exchanger 14 for exchanging heat with the cleaning water in the tank 13 . The control unit 31 performs switching control on the heat exchanger 14, so that it becomes a condenser in at least one of the cleaning and heating rinsing strokes, and becomes an evaporator in the drying stroke.

[0021] With such a configuration, the heat pump unit 30 can transfer the surrounding heat to the washing water during the washing and heating ...

Embodiment 2

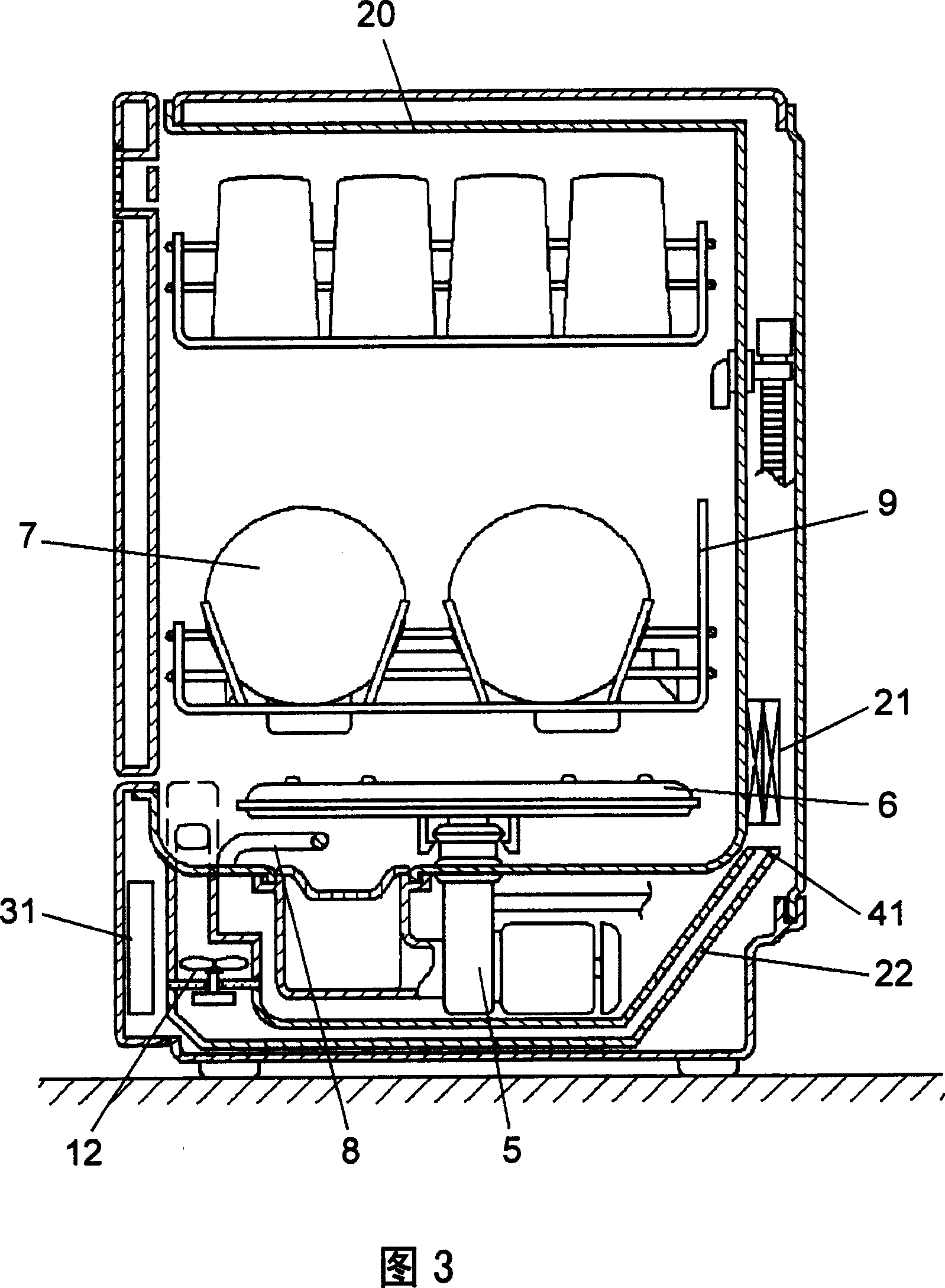

[0031] Fig. 3 is a side sectional view of the dishwasher shown in Embodiment 2 of the present invention. As shown in FIG. 3 , the dishwasher of the second embodiment is provided with a Peltier element 21 in contact with the outside of the rear wall of the washing tank 20 , instead of the heat pump unit 30 in the first embodiment. In addition, since other components in the dishwasher are the same as those in Embodiment 1, description thereof will be omitted here.

[0032] Next, the operation and function of the dishwasher in the second embodiment having the above-mentioned structure will be described. Before washing the tableware, the user first loads various tableware 7 into the tableware basket 9 , and then loads the tableware basket 9 into the cleaning tank 20 . After the dish washer starts to work, the washing pump 5 is driven, and the pressurized washing water is sprayed from the washing nozzle 6 to various tableware 7 .

[0033] In the washing process and the heating an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com