Powerful asynchronous wind driven generator with duplex winding in dual speeds

A technology of wind power generators and double windings, applied in the direction of asynchronous induction motors, windings, electromechanical devices, etc., can solve the problems of motor heating, large size, affecting motor operation and power generation, and achieve stable operation, high efficiency, and practical structural design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

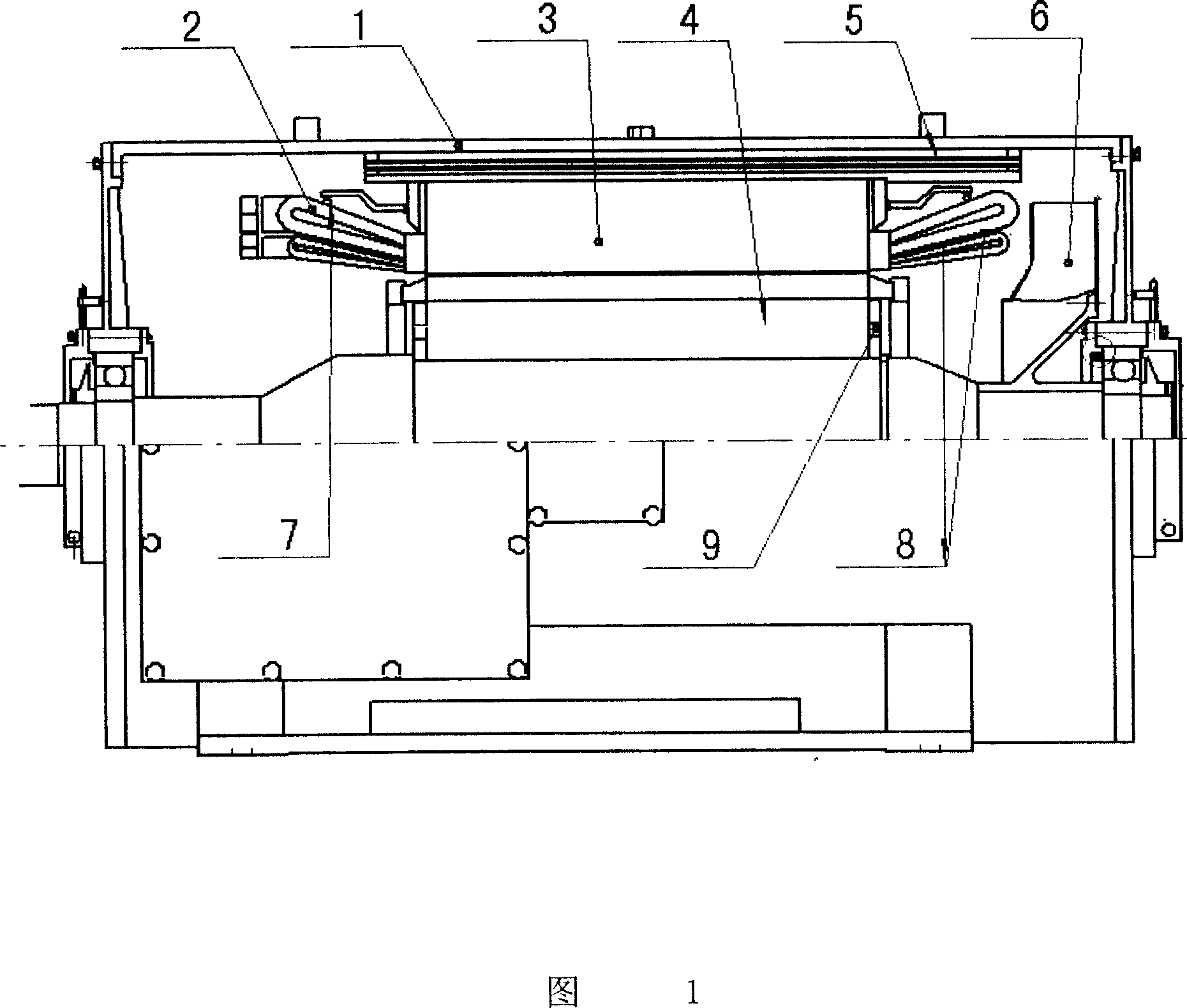

[0009] Referring to Fig. 1, this embodiment includes a casing 1, a formed stator winding 2, a stator core 3, and a rotor 4. The casing 1 is made into a water-cooled interlayer, and a ventilation pipe 5 is embedded in the interlayer of the casing 1. Two sets of Connected into double-molded stator windings 2 with different numbers of poles, and a centrifugal fan 6 is installed on the rotor. The soft end hoops 7 at the ends of the forming winding 2 are bound, and the two windings are separated by double soft end hoops 8 intermittent bindings. The rotor core 3 is provided with axial ventilation holes 9 . Centrifugal fan 6 presses the hot air generated on the rotor from the non-drive end into the water jacket ventilation pipe for heat exchange, and the cold air after heat exchange cools the end of the stator winding, and at the same time, axially enters the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com