Minitype constant temperature chiller

A freezer and constant temperature technology, applied in the field of small constant temperature freezers, can solve problems such as damage, high system cost, and thermal shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

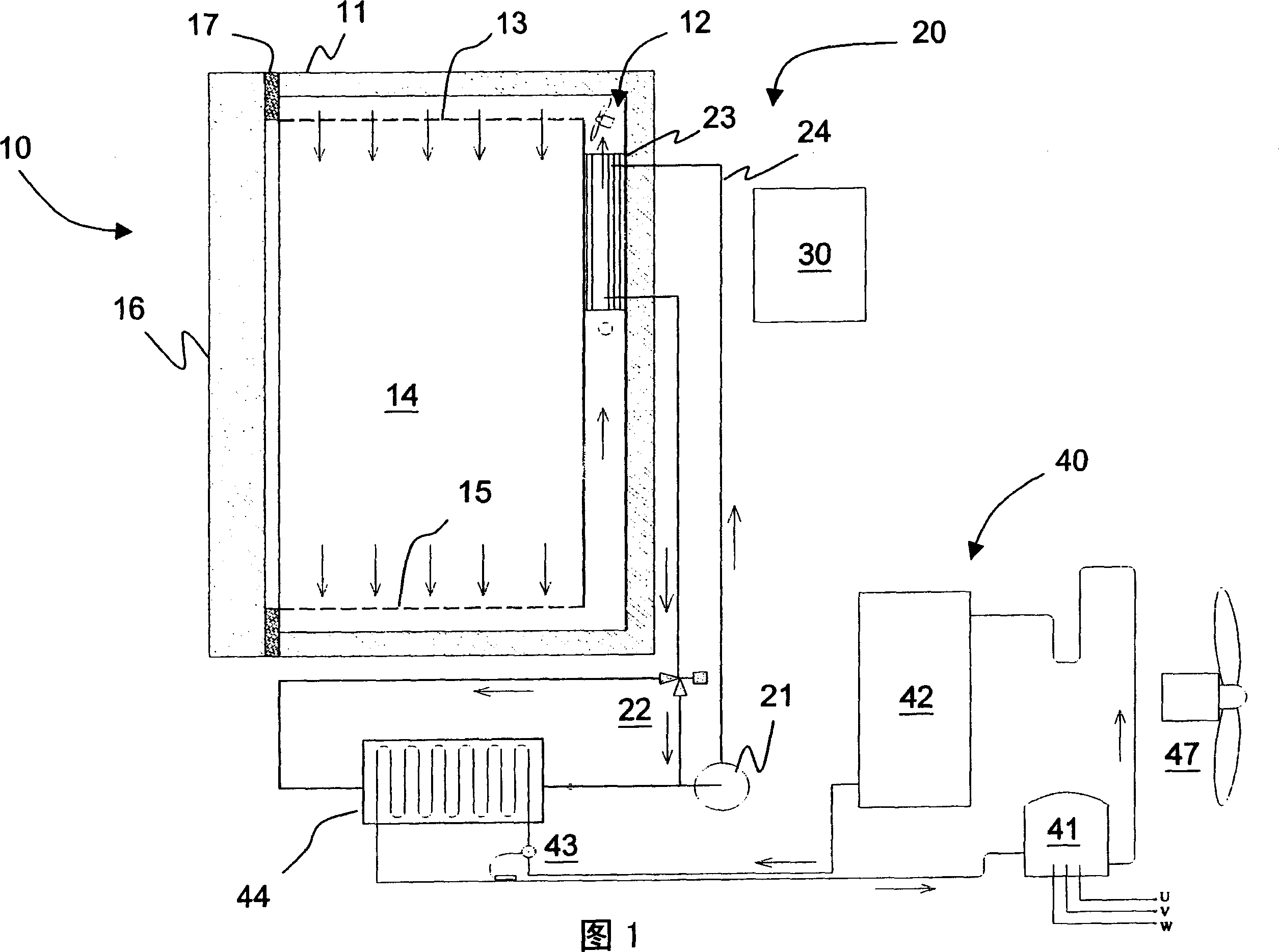

[0050] According to the disclosed small constant temperature refrigerator of the present invention, it is applied on a load body, which is called control volume (control volume) theoretically. Firstly, it is explained by taking the box body 10 as an example. Please refer to FIG. 1, which includes a box body body 10, a secondary refrigerant (secondary coolant) circulation system 20, a constant temperature control system 30 and a frequency conversion refrigeration system 40, the inside of the box body 10 has an accommodating space 14, the outer side is an insulation layer 11, and has a door leaf 16, and the seams are used The door leaf liner 17 prevents external heat energy from entering the accommodating space 14 . The secondary refrigerant circulation system 20 includes a heat exchanger 23, a pipeline 24, a three-way valve 22, and a pump 21; the inverter refrigeration system 40 includes an inverter compressor 41, a fan 47, a condenser 42, an expansion valve 43, and an evaporati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com