Tricolor LED mixed color apparatus used for direct lighting LED backlighting source

An LED backlight, three primary color technology, applied in optics, nonlinear optics, instruments, etc., can solve the problems of package product size limitation, lamp position arrangement and quantity limitation, etc., to improve the color mixing effect and increase the optical path. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

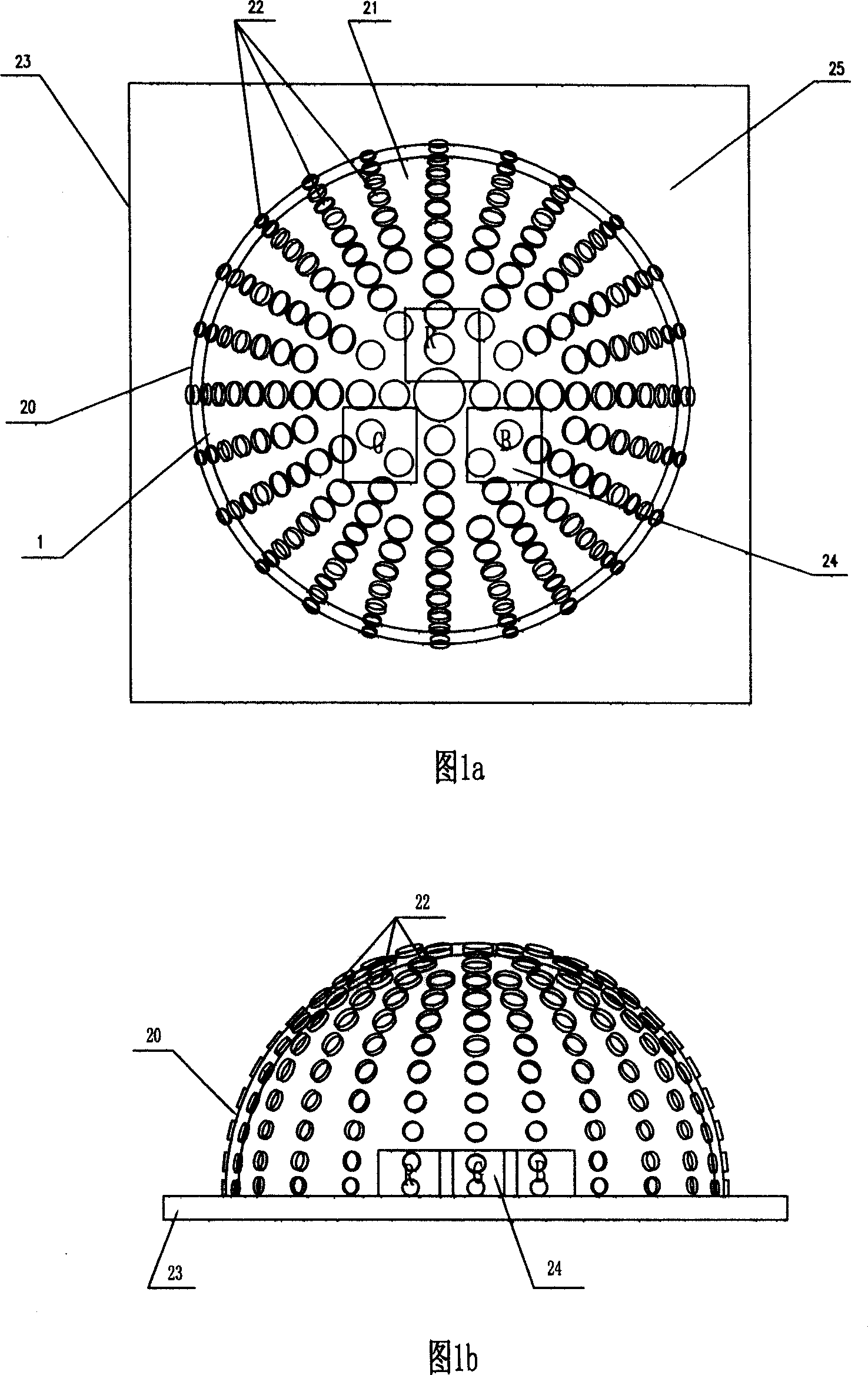

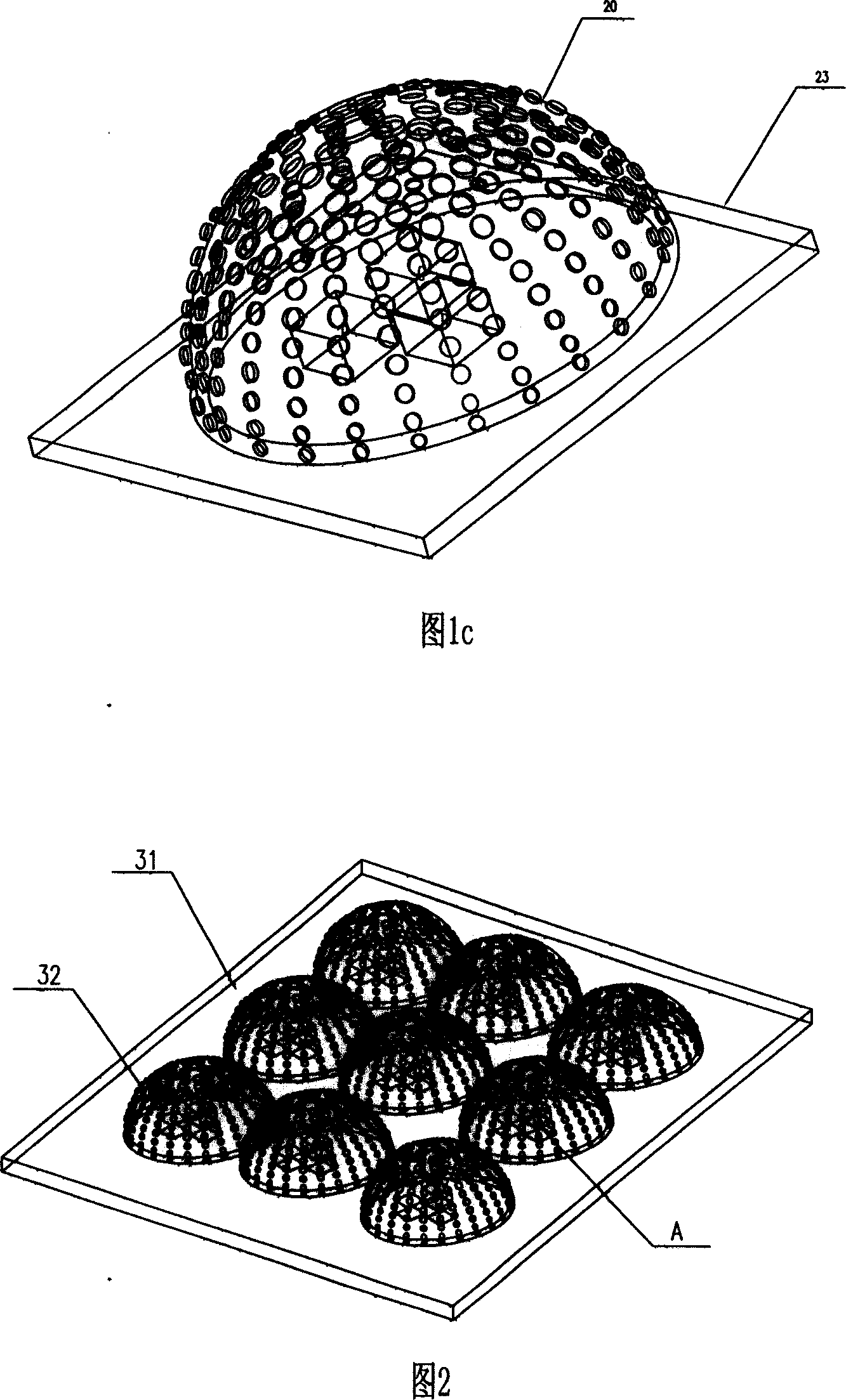

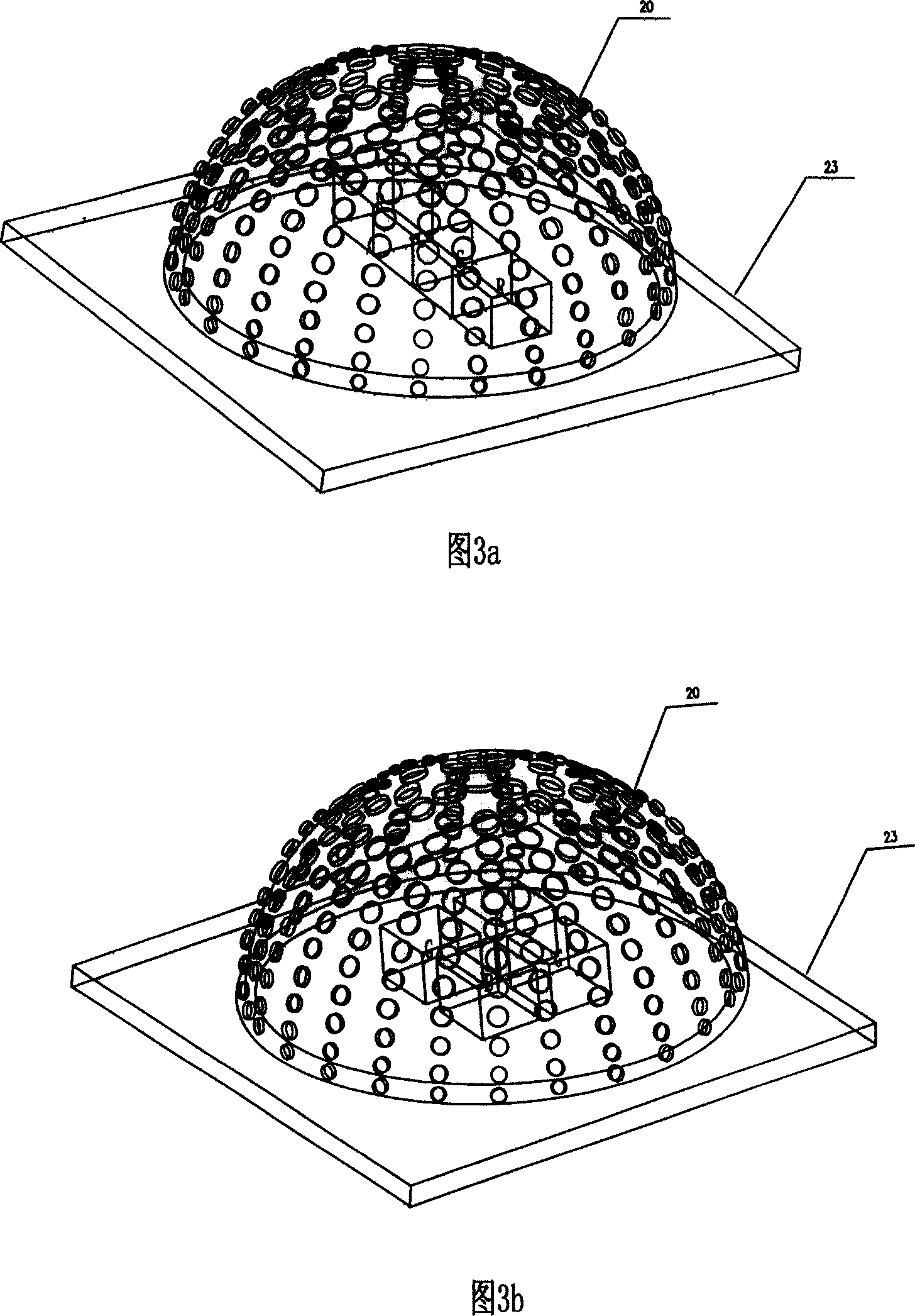

[0019] As shown in Fig. 1 and Fig. 2, the three-primary-color LED color-mixing device used for the direct type LED backlight source of the present invention comprises a substrate 23 and a three-primary-color LED 24, and the three-primary-color LEDs are separated from each other and installed on the substrate, and the surface of the substrate Set the outer cover 1, which is the spherical crown molding part of the color mixing device. On its surface, a layer of reflective material 21 that does not absorb light is plated. The reflective material 21 is plated according to the distribution of dots 22, and the dots are based on LED The arrangement and the distribution of light intensity are set. The LEDs distributed on the surface of the substrate are concentrated directly under the package lens. The arrangement order of the three primary color LEDs is not particularly limited. LEDR, LEDG, and LEDB are arranged linearly or squarely. cloth, its luminous center is directly opposite to ...

Embodiment 2

[0022] As shown in FIG. 4 , for the shape of the color mixing device, besides the spherical cap structure, it can also be made into a cube structure. For the color mixing device 50 of the square structure, a layer of non-absorbing reflective material 51 is plated on its upper surface, and the reflective material 51 is plated with dots 52. The light emitting diode LED is placed directly below the color mixing device and placed on the substrate. 53 , the substrate 53 is plated with a reflective substance that does not absorb light.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap