Relay terminal device of circuit breaker

A technology for relay terminals and circuit breakers, which is applied in the direction of circuit breaker parts, switch terminals/connections, protective switch terminals/connections, etc. Solve problems such as terminal shape and size restrictions, and achieve the effect of convenient wiring work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

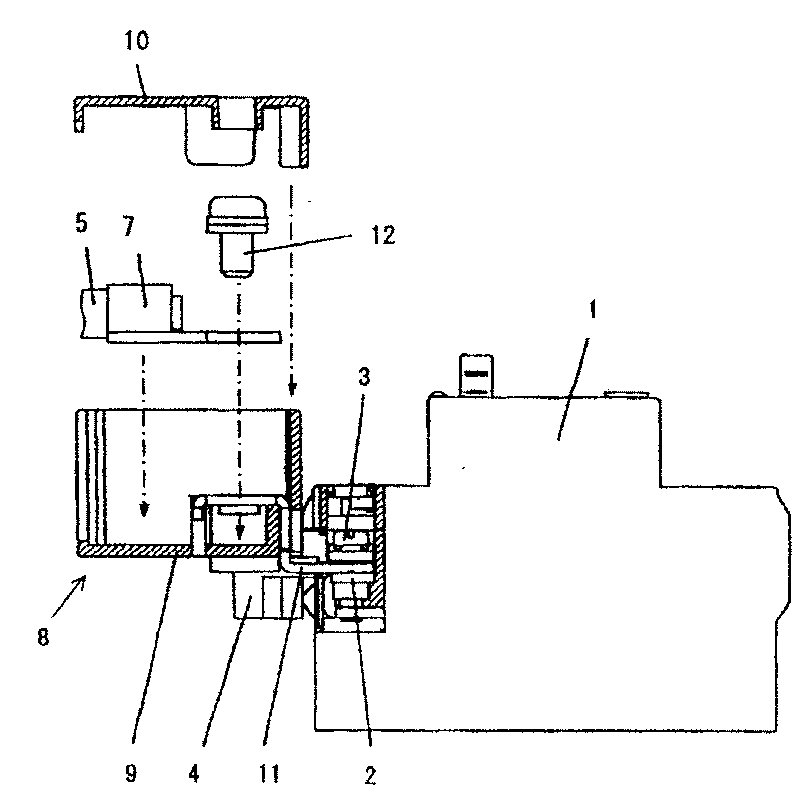

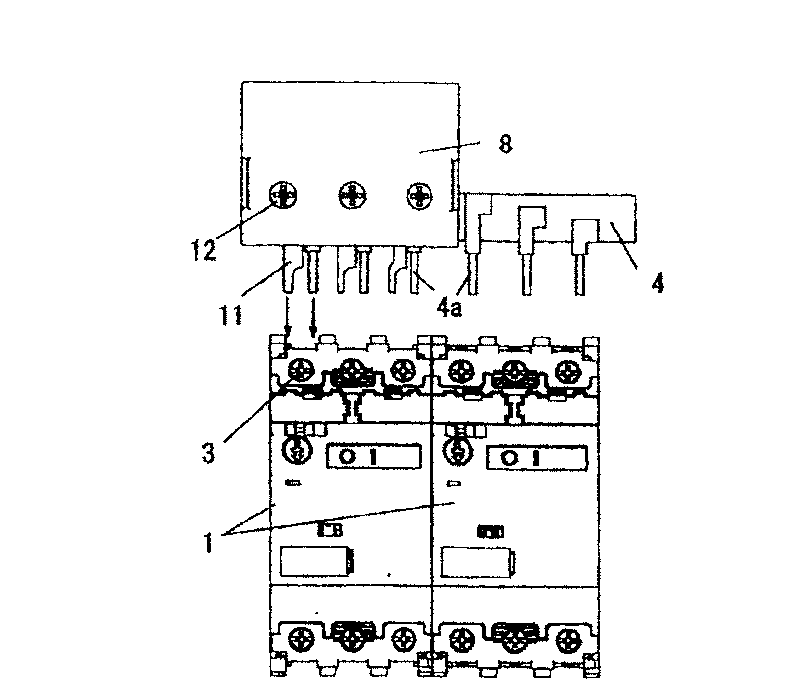

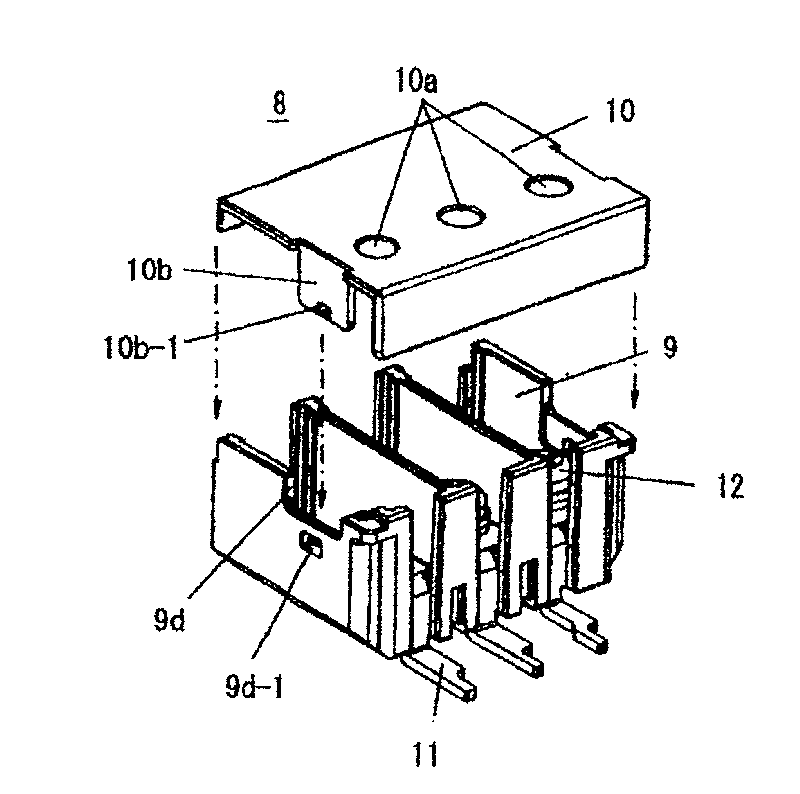

[0026] Below, according to Figure 1 to Figure 6 The shown examples illustrate the implementation of the present invention. in, figure 1 It is an exploded sectional view of the relay terminal block externally installed on the circuit breaker, figure 2 It is a plan view of the arrangement when the relay terminal block is connected to the circuit breaker, image 3 It is an exploded perspective view of the relay terminal block, Figure 4 is the detailed structural diagram of the box-shaped enclosure, Figure 5 It is a detailed structural diagram of the upper cover, Image 6 is a detailed structural diagram of the terminal board, and in addition, in the diagram of the embodiment, for the Figure 7 Corresponding components are assigned the same reference numerals, and descriptions thereof are omitted.

[0027] First, in figure 1 Among them, the circular crimping terminal 7 is attached to the electric wire 5 (rubber insulated flexible cable) arranged in a detour in the pane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com