Jig for inclined bent axle processing

A tooling fixture, oblique bending shaft technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of high processing cost and cumbersome processing methods, and achieve the effect of simple structure, convenient management and easy manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

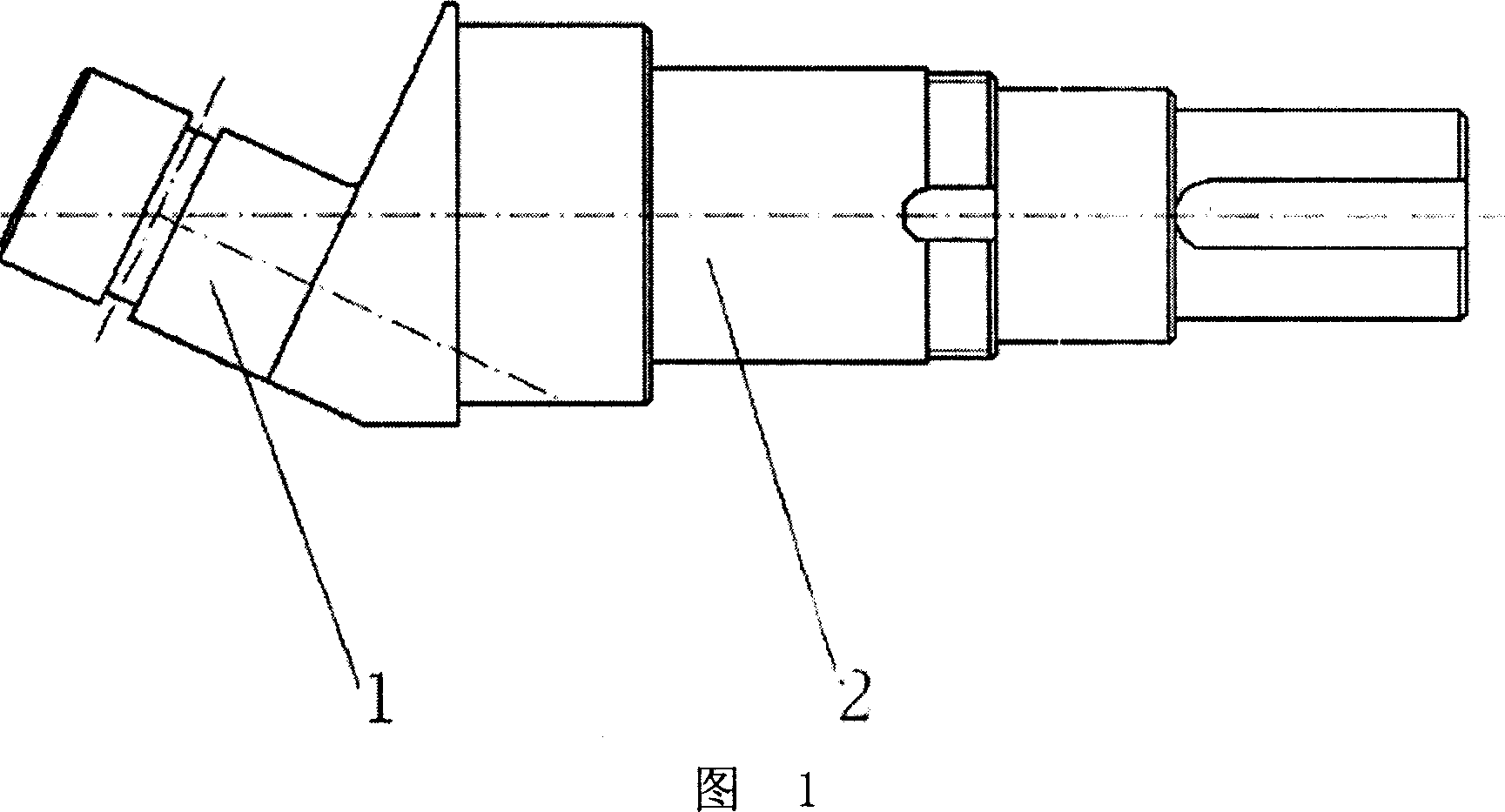

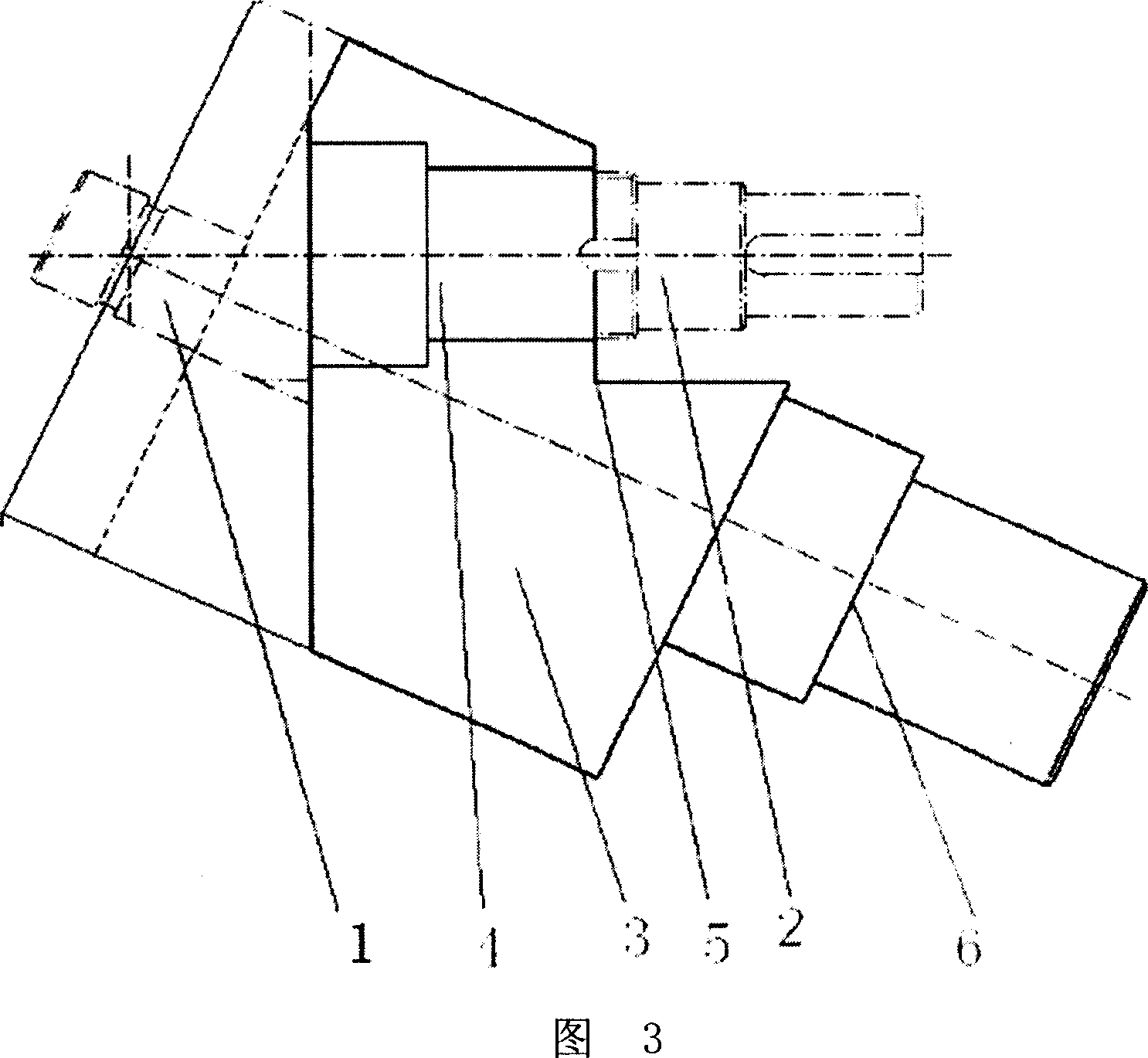

[0011] In Fig. 1, one of the oblique shafts for plunger pumps to be processed is given, wherein the oblique shaft part 1 at the left end of the oblique shaft, the straight shaft part 2 of the oblique shaft, and the oblique shaft part of the oblique shaft The part and the straight axis part are oblique. The difficulty of its processing lies in the determination of the inclination angle of the oblique axis at the left end during the processing.

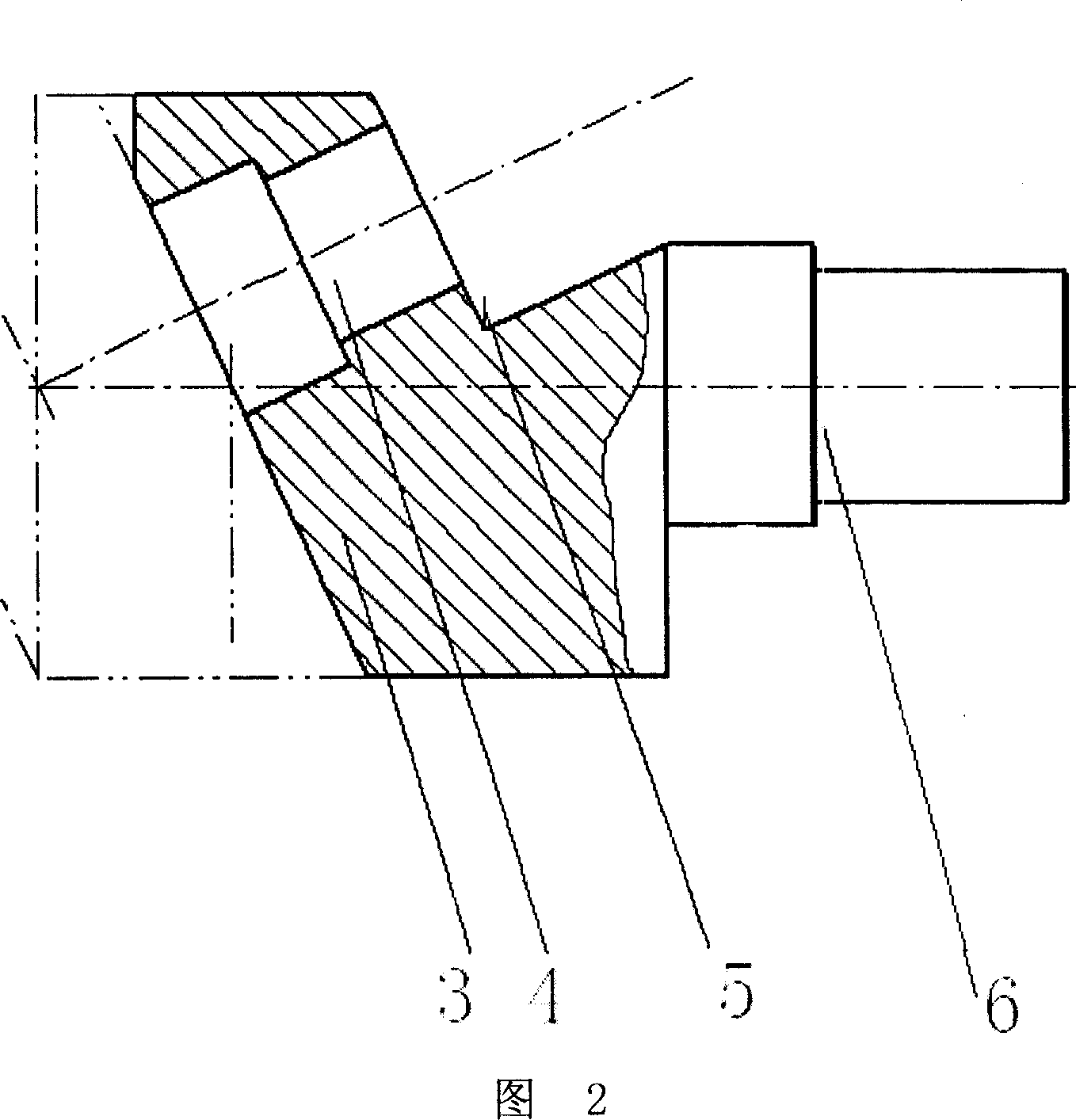

[0012] Fig. 2 has shown the structural shape of clamp embodiment of the present invention, and when manufacturing this clamp, earlier it is processed into three sections of stepped cylinders, and its right end stepped part forms stepped straight axis 6; Cut out an inclined surface to become an inclined part. The angle between the normal line of the inclined surface and the axis of the straight axis is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com