Thawing combined parts for refrigerator and thawing chamber

A technology for assemblies and thawing chambers, applied in lighting and heating equipment, food preservation, household appliances, etc., can solve the problems of shortening the thawing time and not being able to thaw the inside of frozen objects more effectively

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

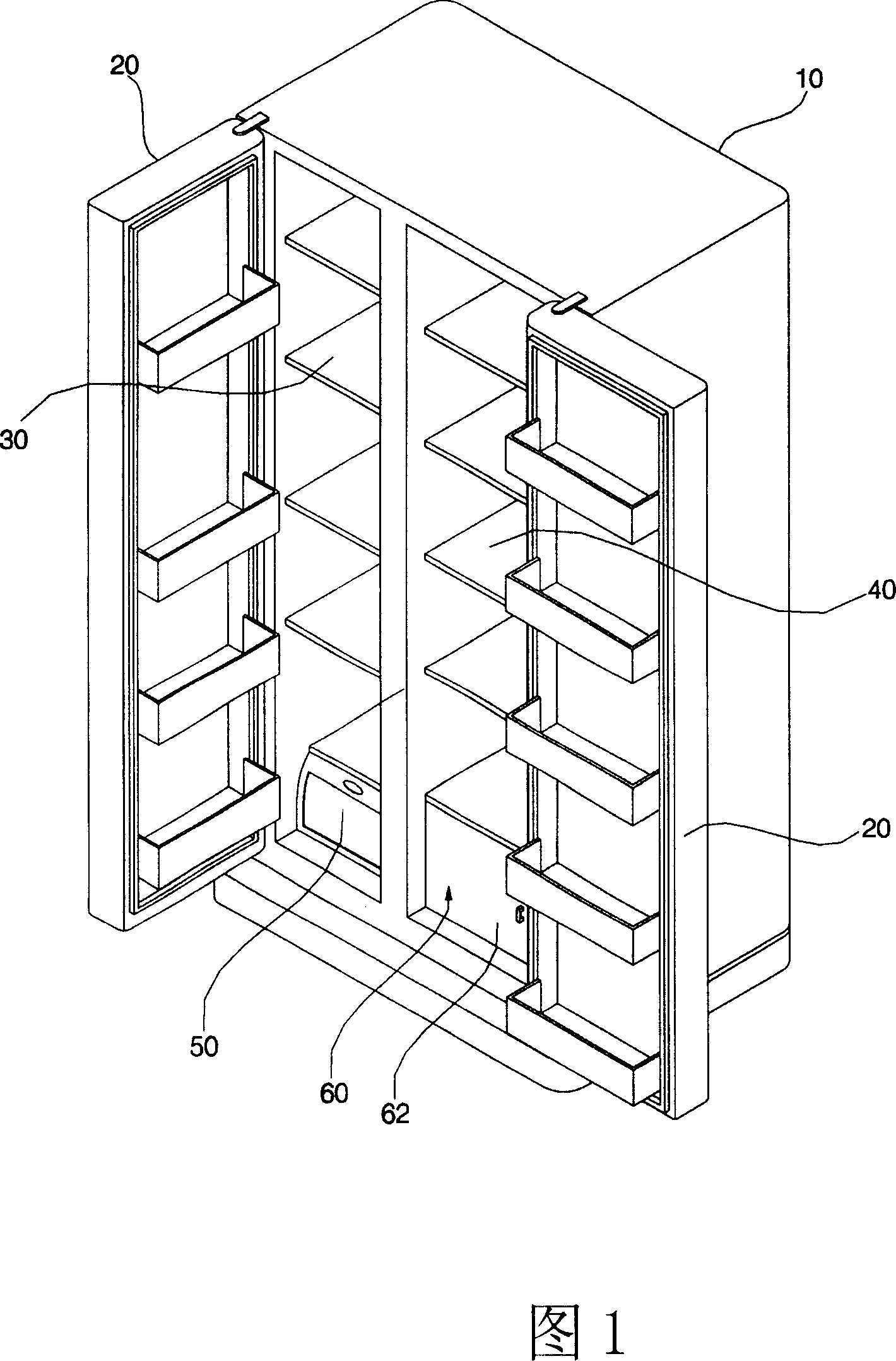

[0039] As shown in Figure 1, the present invention comprises: the main body 10 that constitutes external shape; Be arranged on the door 20 of the front of above-mentioned main body 10; Room 60.

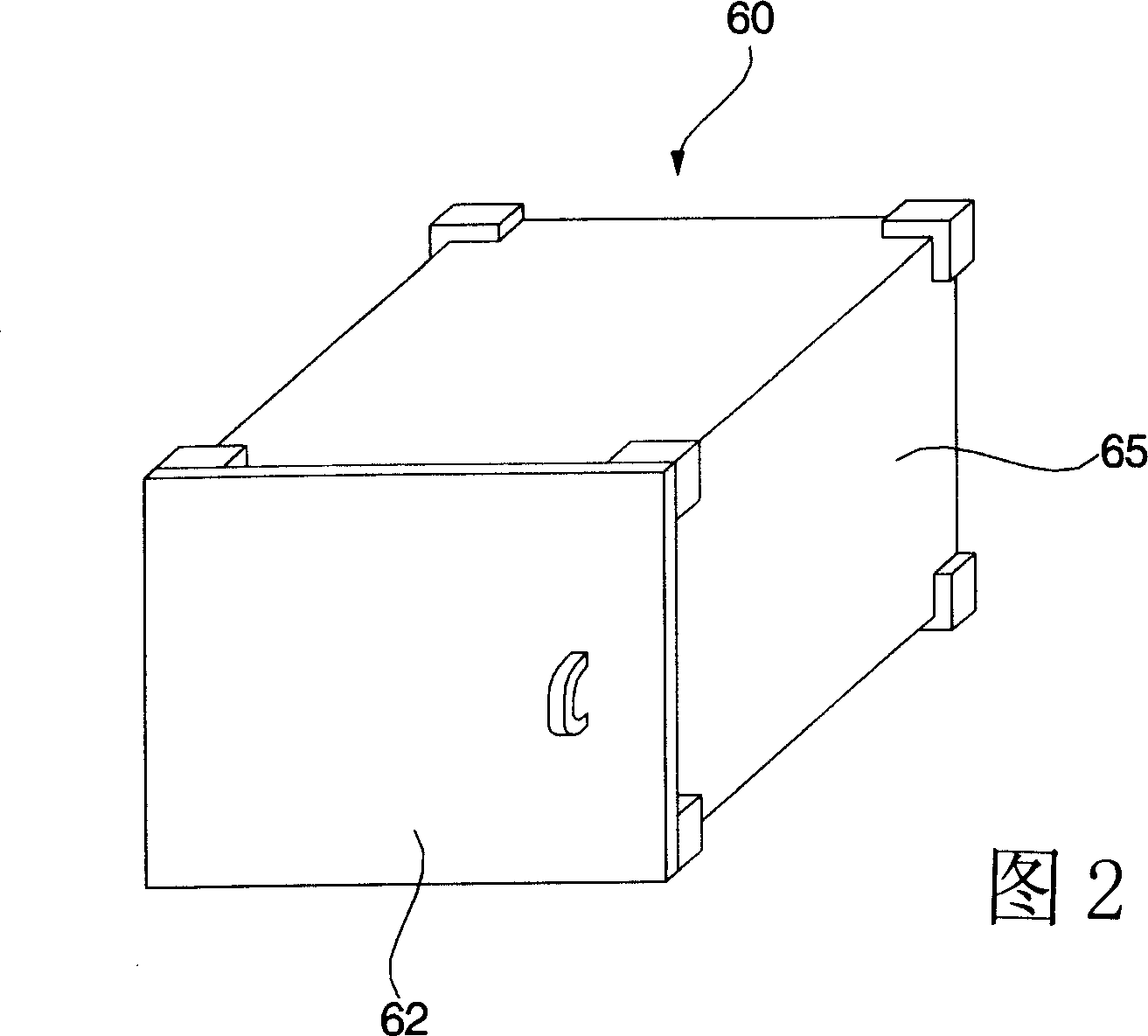

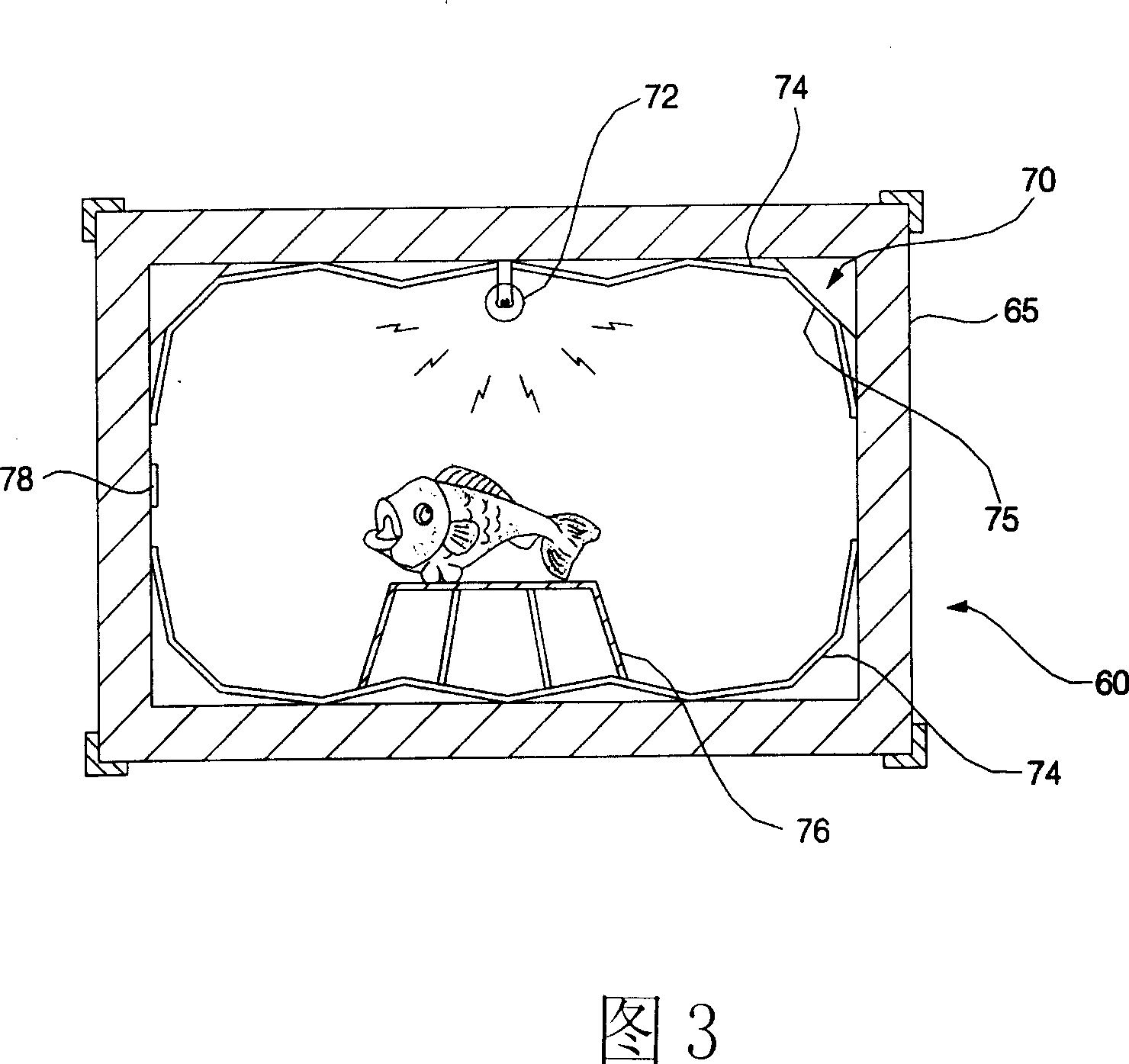

[0040] As shown in Figure 2 or Figure 3, the thawing chamber 60 of the present invention includes: the thawing chamber body 65 that is arranged in the inside of the above-mentioned main body 10 and occupies a part of the space inside the above-mentioned main body 10; Close the thawing chamber door 62 in the front of the above-mentioned thawing chamber body 65. The thawing chamber 60 is provided with a thawing assembly 70 inside, and the thawing assembly generates radiant heat to thaw the frozen objects.

[0041] The above-mentioned thawing chamber body 65 may also be integrally formed with the above-mentioned main body 10, and in order to prevent heat from being transferred to the above-mentioned main body 10, it is preferably made of a heat insulating material.

[0042] The above-m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com