Tension machine dynamometer

A technology of tensioning machine and dynamometer, which is applied in the field of cargo binding, can solve the problems of loose and slipping cargo, inability to accurately know the safety status of cargo, damage to cargo, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

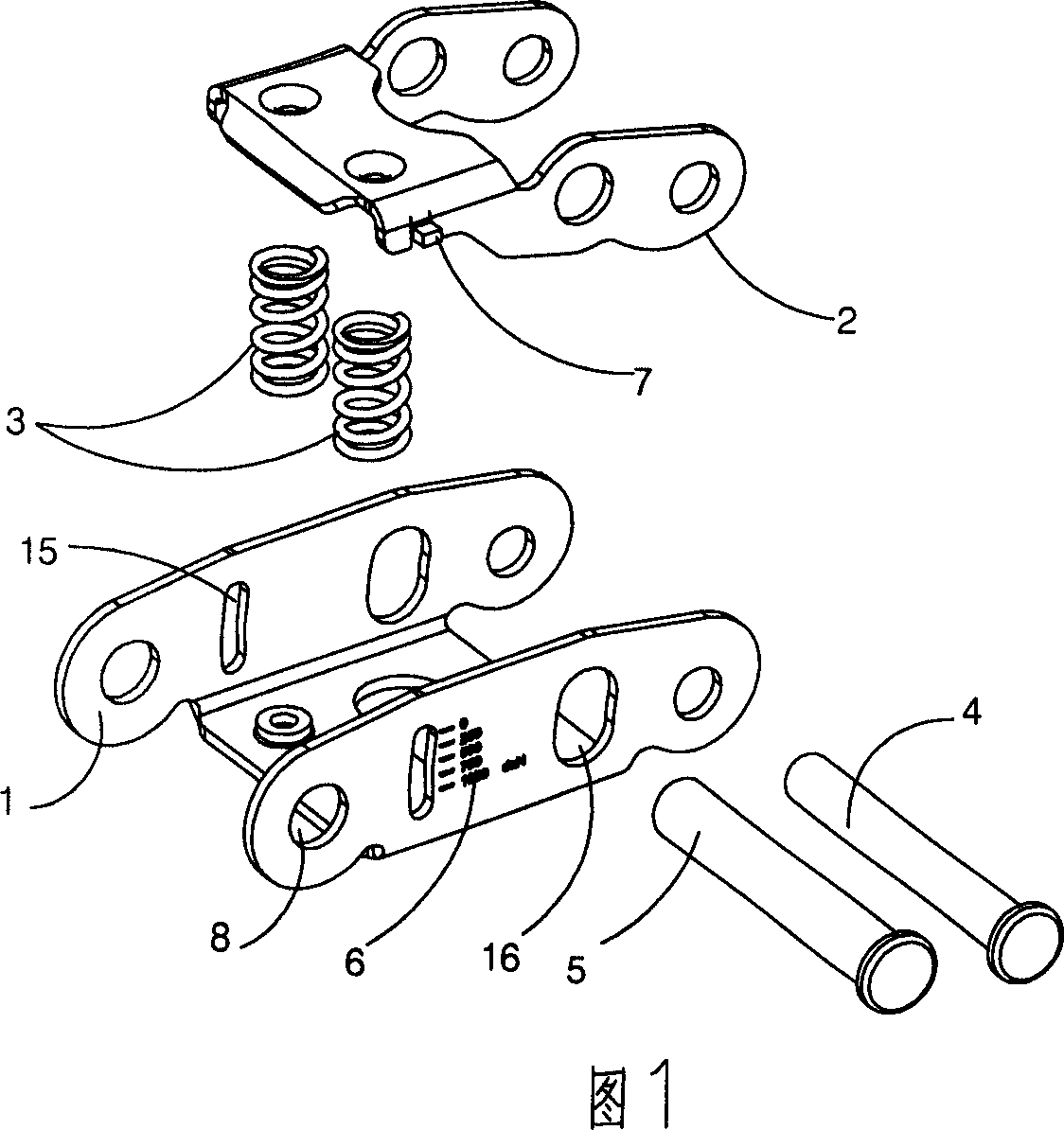

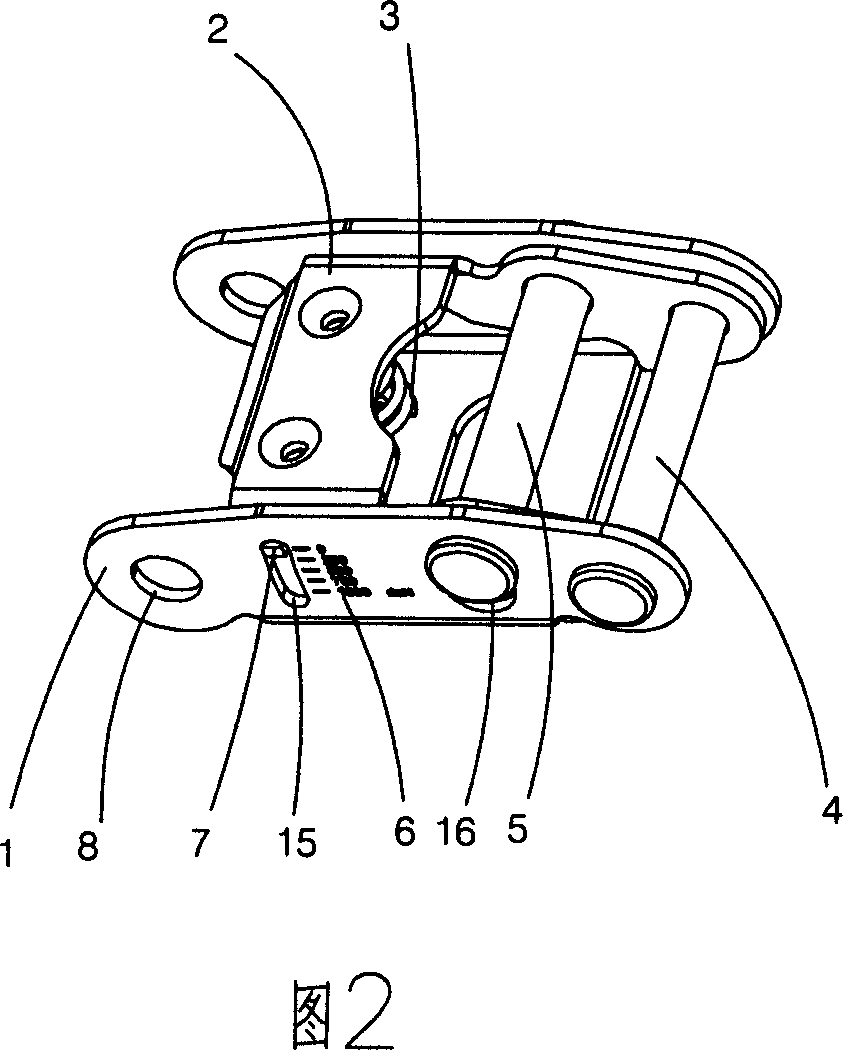

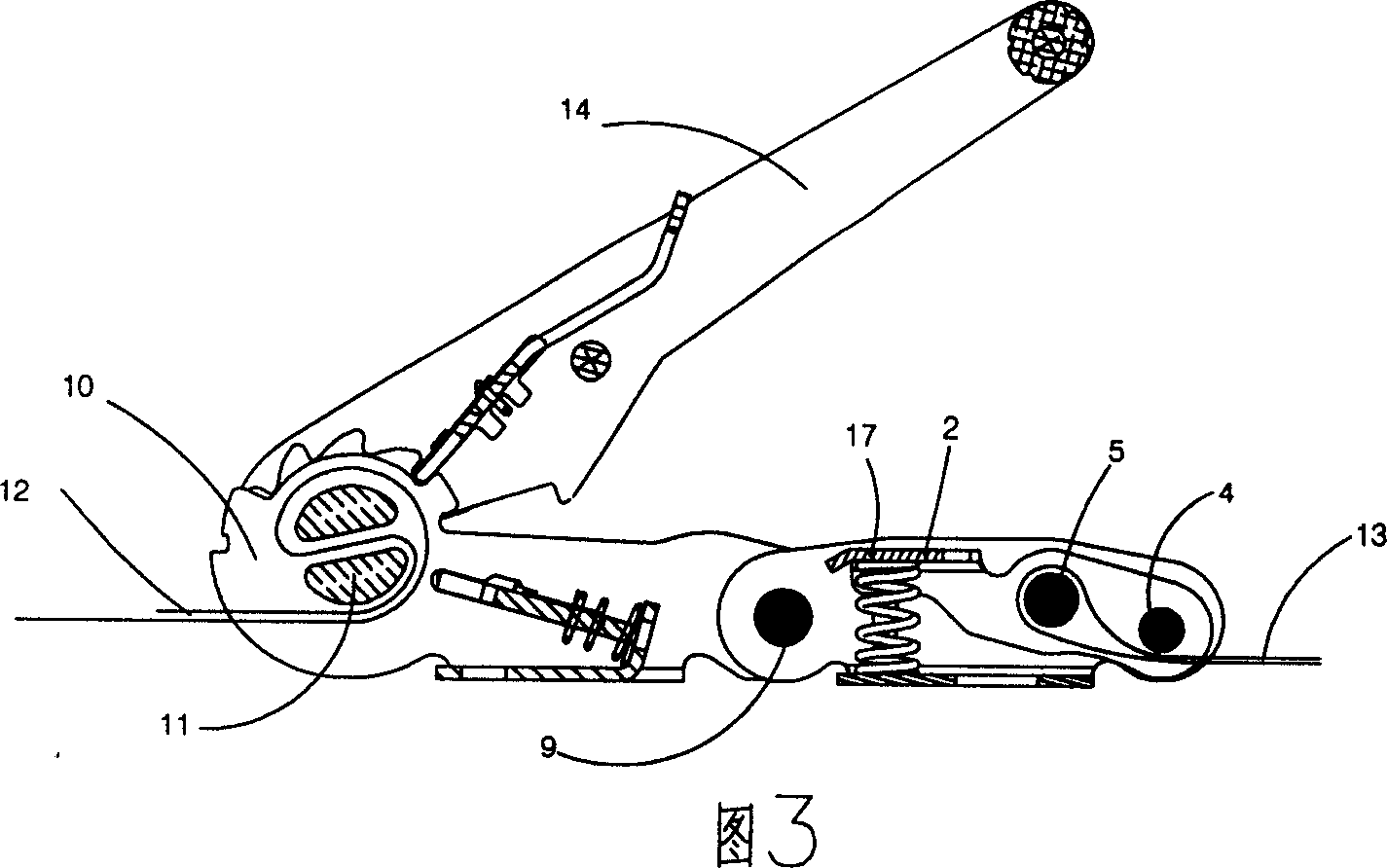

[0015] As shown in Fig. 1 and Fig. 2, it comprises housing 1 and spring 3 described in this embodiment, is provided with pointer indication hole 15 on housing 1, is provided with tension value scale 6 beside pointer indication hole 15, and spring 3 is provided with In the housing 1 , one end of the spring 3 is positioned and connected to the housing 1 , and the other end of the spring 3 is connected to the stretching mechanism 17 . The stretching mechanism 17 is provided with an indicator needle 7 corresponding to the pointer indicating hole 15 . The stretching mechanism 17 described in this embodiment includes a gland 2, a fixed shaft 4 and a movable shaft 5, the gland 2 is connected to the housing 1 through the fixed shaft 4, and the fixed shaft 4 and the movable shaft 5 can be connected by bolts. accomplish. Between the gland 2 and the housing 1, the rotation limit connection is realized through the movable shaft 5 and the waist-shaped hole 16. During implementation, the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com